Supplying the space station, preparing to put humans back on the moon

By Hang Woon Lee and Koki Ho|December 2019

The Space Logistics Technical Committee fosters development of integrated space logistics capabilities that enable safe, affordable and routine space-faring operations.

Northrop Grumman and SpaceX completed Commercial Resupply Services missions to carry cargo to the International Space Station this year. Space X’s CRS 17 and 18 launched in May and July; Northrop Grumman’s Cygnus NG-11 launched in April. Phase 2 of NASA’s Commercial Resupply Services contract began with the launch of Cygnus NG-12 to the ISS in November. SpaceX’s CRS 19 was scheduled for December.

In its efforts to establish a planned space station, China deorbited Tiangong-2 in July, marking the official end of its experimental space station mission. China is set for the launch of Tianhe for its modular space station.

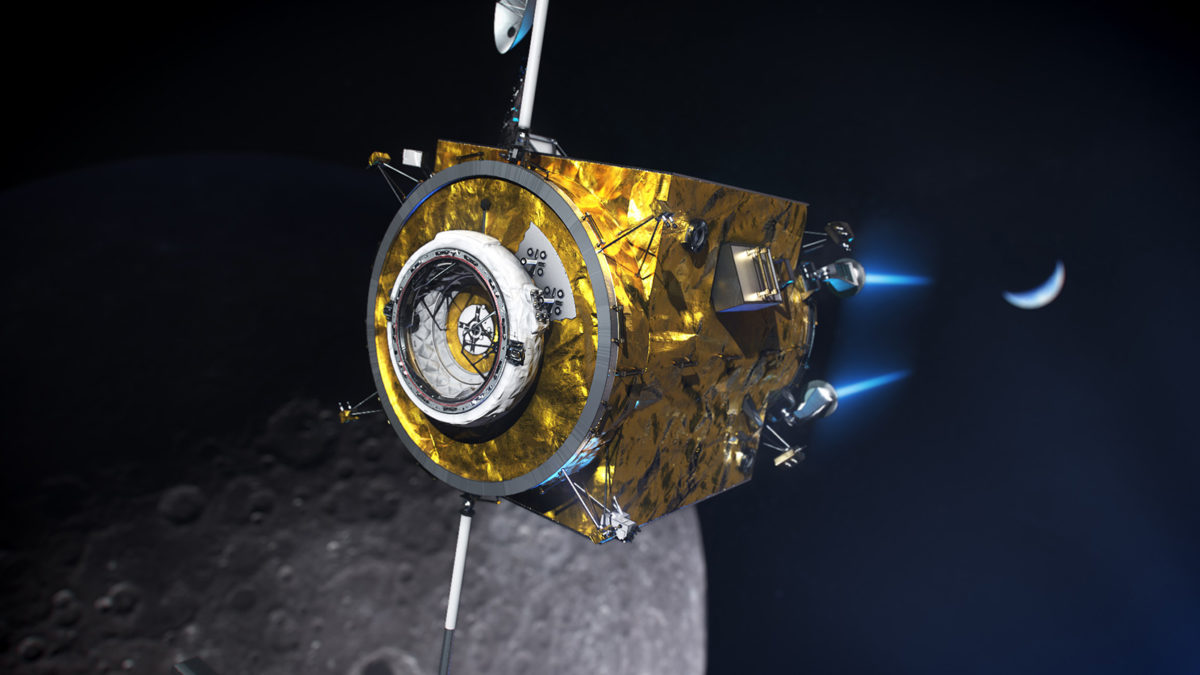

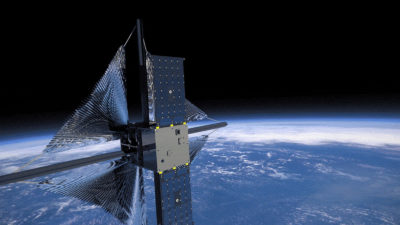

NASA made a significant movement in the ongoing development of the crewed lunar spaceflight program. In May, NASA Administrator Jim Bridenstine announced that the return-to-the-moon program would be called Artemis, after the twin sister of Apollo. Artemis envisions the use of the lunar Gateway to provide sustainable transportation to the lunar surface. Gateway, in a near-rectilinear halo orbit, will be a transportation and logistics hub for supporting future crewed and cargo missions. In May, NASA awarded Maxar Technologies a contract to build Gateway’s Power and Propulsion Element module. The PPE will provide a high-power solar electric propulsion capability. In August, NASA formally announced a request for proposals for logistics services to Gateway, encouraging commercial partnerships in the cislunar regime with the total offering up to $7 billion.

In February and July, NASA announced the list of scientific payloads and experiments that will fly to the moon as part of the Commercial Lunar Payload Services program. CLPS is a major logistics-based NASA initiative to deliver small-to-medium payloads to the lunar surface as a service that NASA and perhaps others would buy as needed. NASA is using the same commercial approach to procure a human lunar lander system using a public-private partnership — that is, buying a logistics service rather than owning and operating the system.

On the academic side, in September, the Space Systems Optimization Laboratory at the University of Illinois at Urbana-Champaign (now moved to the Georgia Institute of Technology) completed a one-year study for NASA to analyze the strategy of deploying in-situ resource utilization systems while considering the overall efficiency of the space logistics architecture. The study introduced a new multifidelity space infrastructure optimization framework that can perform efficient and reliable system-level architecture trade studies. Also this year, researchers at the Massachusetts Institute of Technology developed a new analysis method called Mass, Crew time, and Risk-based Optimization of Supportability Strategies, or MCROSS, which enables forecasting and optimization of spares mass and maintenance crew time for a given level of risk, including options for in-space manufacturing. The development effort started in 2017 as part of a NASA Space Technology Research Fellowship in collaboration with NASA’s Langley Research Center in Virginia. MCROSS informs NASA technology investment and mission planning activities.

Contributors: Olivier de Weck, Andrew Owens and Robert Shishko