Structures tested; modeling developed

By HARRY H. HILTON|December 2019

The Structures Technical Committee works on the development and application of theory, experiment and operation in the design of aerospace structures.

In July, NASA demonstrated that the Orion spacecraft launch abort system can jettison astronauts to safety during launch emergencies. The test was another milestone for the Artemis program, which is dedicated to sending Americans back to the moon and eventually to Mars. During the test, a representative Orion crew module was launched from Cape Canaveral on a modified Peacekeeper missile built by Northrop Grumman. The test version Orion experienced maximum expected high-stress aerodynamic loadings, traveled to a 6-mile (9.7-kilometer) altitude and reached Mach 1.3 when the planned abort sequence triggered.

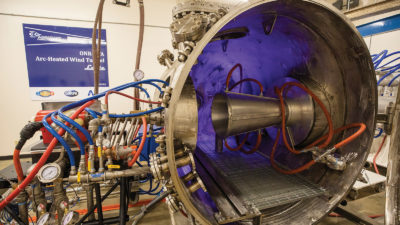

In June, NASA began structural testing of the largest component for the United States’ new deep space rocket, the Space Launch System, at NASA’s Marshall Space Flight Center in Alabama. The liquid hydrogen tank, which is 64.6 meters tall and has a diameter of 8.4 m, comprises two-thirds of the rocket’s core stage, and it holds, at minus 217 degrees Celsius, the approximately 2 million liters of supercooled liquid hydrogen necessary to power the RS-25 engines. During those tests, which wrapped up in September, dozens of hydraulic cylinders in a 66-meter-tall test stand pushed and pulled the tank, subjecting the test article to the same stresses endured during liftoff and flight.

The Mechanics of Structure Genome project at Purdue University continued its ongoing multiscale modeling effort that seeks to provide a new, unified approach to modeling composite anisotropic heterogenous structures. MSG simplifies multiscale composite modeling by determining and executing only necessary analyses to sufficiently capture the relevant physics. MSG also provides a rigorous yet efficient approach to handling complex buildup structures. The Purdue team developed a companion code, SwiftComp, as constitutive modeling software for virtual structures and materials testing, as well as for executing finite element analysis codes for efficient, high-fidelity composite material modeling. This year, the MSG project developed an MSG-based multiscale Timoshenko model, an efficient and accurate multiscale method for predicting failure envelopes that uses MSG-based thermo-viscoelastic multiscale modeling and AI-assisted, MSG-based multiscale modeling.

Arizona State University continued developing a computationally efficient multiscale modeling framework for nanoengineered composites. With support from the Office of Naval Research, investigators studied material behavior across multiple length scales while quantifying analysis uncertainty. These efforts in nanotechnology led to the fabrication and application of carbon nanotube-enhanced carbon fiber reinforced polymer composites and nanoengineered novel architectures (such as radially grown fuzzy fiber composites). This approach was used to characterize elevated-temperature mechanical properties of thermosets reinforced with randomly dispersed carbon nanotubes.

GKN Fokker and Gulfstream continued to assess thermoplastic composites as primary aircraft structures. High out-of-plane strength and sustainability/recyclability are some of the thermoplastic advantages. Efforts to develop cost-effective manufacturing technologies continue across the globe — particularly in the Netherlands.

Boeing continued to refine the design of the proposed hypersonic, passenger-carrying airliner it unveiled at the 2018 AIAA Aviation Forum in Atlanta. It is similar to an uncrewed hypersonic surveillance and reconnaissance concept the company presented in January; both have a general delta-wing configuration with dual rear fins, streamlined fuselage and sharp nose. The vehicle could travel at up to Mach 5 and cross the Atlantic and Pacific oceans in two and three hours, respectively, Boeing said.

Boeing made public its newest Transonic Truss-Braced Wing design in January at the AIAA SciTech Forum in San Diego. Researchers say this aircraft would fly higher and faster than the previous TTBW concepts. Originally, the TTBW was designed to fly at Mach 0.70 to Mach 0.75; engineers modified the design for more aerodynamic efficiency while flying at Mach 0.80. By adjusting the wing sweep angle, the resulting optimized truss can more efficiently carry lift, thus allowing designers to increase the wingspan to 51.8 m with a folding wing concept. The integrated design is expected to increase the aircraft’s cruise speed.

Contributors: Siddhant Datta, Zhenning Hu, Bruce D. Willis, Michael Wolff and Wenbin Yu