Researchers aid development of AI, additive manufacturing

By ANDREW C. OLLIKAINEN|December 2018

The Non-Deterministic Approaches Technical Committee advances the art, science and cross-cutting technologies required to advance aerospace systems with non-deterministic approaches.

From deriving material allowables to design optimization to reliability-based fleet management to service life extension programs, the field of non-deterministic approaches directly impacts how risk is managed and airworthiness is assured and maintained. This field of applied mathematics deals with uncertainty with a foundation of statistics and probability. Researchers develop the methods and techniques that enable the aerospace enterprise to, for instance, identify and quantify uncertainty in all stages of a vehicle’s life cycle.

Many artificial intelligence and machine learning programs rely heavily on techniques common to non-deterministic approaches. AI is already ubiquitous when discussing autonomy and AI is now being applied to “classical” NDA such as the optimization of vehicle design, and the fusion of data input from multiple sources. More progress on this front was made this year.

In January, a team of researchers from the Massachusetts Institute of Technology, Naval Postgraduate School and Brown University presented the application of statistical learning in the design optimization of a specialized hydrofoil. In July, DARPA issued a program announcement for a streamlined contracting vehicle for basic and applied research in AI. In August, the first opportunity under the Artificial Intelligence Exploration program was listed for automated scientific knowledge extraction.

Accounting for uncertainty in multidisciplinary design optimization and risk analysis involves a very large number of iterations. As the number of variables in the system increases, so too does the computational resources needed to solve these problems. Over the course of the year, researchers from government, industry and academia advanced methods to increase the efficiency of solving higher-order problems. Specifically, researchers undertook this kind of NDA work at the U.S. Air Force Research Laboratory, Army Research Lab, Sandia National Labs, the United Technologies Research Center, GE Global Research Center, and at several universities. Several projects benefited from the continuing support of DARPA’s Defense Sciences Office through the Enabling Quantification of Uncertainty in Physical Systems program. This program aims to advance NDA for large-scale, complex systems.

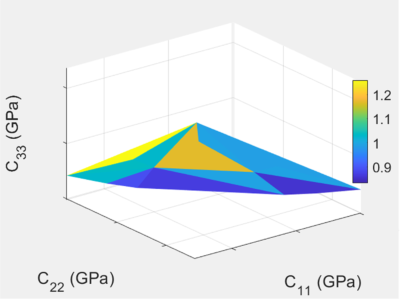

Additive manufacturing and 3D printing were buzz-words in the industry in 2018. In order to benefit from all the possible opportunities these technologies afford, it must be proven that parts made by these processes are safe to fly. Understanding the impact on structural risk requires quantifying the uncertainty associated with how variability in manufacturing parameters impact scatter in mechanical properties. Southwest Research Institute, University of Michigan, Ohio State University, University of Tennessee, Texas A&M, Vanderbilt University and University of Wisconsin worked to improve our understanding of the uncertainties involved in material variability and how to model them.

In the photo: Additive manufacturing enables the creation of lightweight parts, like this lattice structure produced at Southwest Research Institute in Texas. The variation in geometry and the uncertainty in material properties must be considered to qualify these optimized designs. Credit: Southwest Research Institute