Aircraft engine community improves standing for operations after recovery

By MICHAEL G. LIST|December 2020

The Gas Turbine Engines Technical Committee works to advance the science and technology of aircraft gas turbine engines and engine components.

The aircraft engine community saw a strong start to the year, with focus on improving manufacturing, sustainability, efficacy of operations and responsiveness to airframers and airliners.

GE Aviation and Boeing celebrated the first flight of the 777X at Paine Field in Everett, Washington, in January. Two GE9X engines powered the widebody aircraft. GE Aviation developed the GE9X engine, which includes 300 3D-printed engine parts in seven components, including fuel nozzles, heat exchangers and low-pressure turbine blades. A second 777X airplane began flight testing in April, and in September, GE Aviation received airworthiness certification from FAA for the GE9X after nearly 5,000 hours of testing.

In February, Pratt & Whitney announced that the first aftermarket 3D-printed part, a fuel system component, would replace conventionally manufactured parts. The joint effort with Component Aerospace Singapore and Singapore-based ST Engineering represented a new application of additive technology for commercial engine maintenance, repair and overhaul, or MRO, operations that will reduce the overall logistics footprint.

In February, Rolls-Royce began manufacturing UltraFan composite fan blades at its Bristol, England, location for a new demonstrator engine with a diameter of 3.556 meters. UltraFan is part of a geared turbofan engine for high bypass ratio and is reportedly the largest fan diameter in development. The engine is being designed to deliver a 25% fuel and emissions reduction over Rolls-Royce’s first-generation Trent engines.

The fall in demand for air travel due to the covid-19 pandemic accelerated in March. Throughout the industry, companies worldwide announced lockdowns, reductions in employees, furloughs and facility closures as they tightened and refocused. Despite the negative business impacts, the engine manufacturers renewed focus on support and MRO of existing fleets.

Pratt & Whitney exploited excess capacity at its MRO partners to conduct upgrades across the Geared Turbofan fleet. The PW1100G, which powers the Airbus A320neo, underwent a material change in the third stage of the low-pressure turbine and replacement of the main gearbox to increase durability. In August, Pratt & Whitney announced completion of the turbine and gearbox upgrades for IndiGo of India.

In July, Rolls-Royce announced that no Boeing 787 aircraft remained grounded for durability problems, positioning the fleet for improved operations as demand increases. Rolls-Royce redesigned intermediate pressure compressor blades and high-pressure turbine blades and replaced intermediate turbine blades for the Trent 1000 TEN engine. In addition to the upgrade efforts, Rolls-Royce piloted improved training and inspection capabilities via Librestream, a digital visualization platform that allows airline technicians to conduct inspections in conjunction with remote experts.

Honeywell Aerospace, based in Arizona, obtained FAA certification in August for a 3D-printed, flight-critical No. 4/5 bearing housing on the ATF3-6 turbofan engine. The engine, designed in the 1960s, powers the Dassault Falcon 20G aircraft for the French Navy. Printing the bearing housing reduces lead-time from two years to two weeks for about a dozen aircraft in operation.

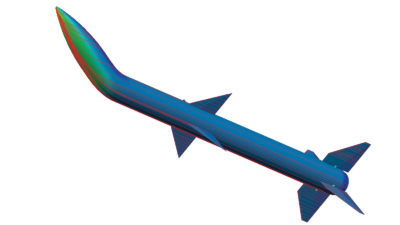

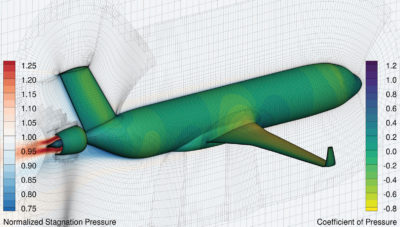

The industry also continued support of advanced aircraft demonstrations for next-generation aviation. In August, NASA’s Armstrong Flight Research Center in California took delivery of an afterburning GE Aviation F414-GE-100 engine to power the Mach 1.42 X-59 Quiet Supersonic Technology X-plane. GE Aviation redesigned the F414 engine operation and controls as well as externals to meet X-59 needs. Lockheed Martin’s Skunk Works in California began the X-59 assembly this year. Once complete, the company will test the aircraft and collect data on quiet supersonic flight to inform regulators as new rules for over-land supersonic flight are considered.