Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

The High-Speed Air-Breathing Propulsion Technical Committee works to advance the science and technology of systems that enable supersonic and hypersonic air vehicle propulsion.

2025 recorded several exciting developments in high-speed air-breathing propulsion ground and flight testing, especially in terms of multidisciplinary efforts combining different propulsion technologies. These included turbojet and detonation engines fused with ram/scramjet propulsion systems to achieve sustained supersonic and hypersonic flight.

In Edmonton, Canada, Space Engine Systems (SES) in July and August performed ground tests based on a hypersonic Los Angeles-to-Sydney trajectory. Aims included validating thrust coefficients and establishing throttling protocols to prevent engine seizure during the turbojet-to-ramjet transition. At the company’s Villeneuve Airport facility in Canada, the precooler-enabled turbojet demonstrated operational performance up to Mach 3 with simulations extending to Mach 5, including windmilling. Full-scale ramjet ground tests achieved sustained hydrogen combustion for up to 30 seconds at fuel flow rates of 0.5-3.0 kilograms per second and air equivalence ratios of 0.3-1.0 k/s, providing confidence in thrust coefficients for a flight-ready ramjet. As the trials simulated full-scale conditions, they also served to optimize and demonstrate a working flame holder design along with an actuated, variable-throat rectangular nozzle.

In May, Venus Aerospace completed the first U.S. flight of a rotating detonation rocket engine (RDRE). The prototype, known as the Venus Detonation Ramjet (VDR2), integrates a ramjet with the RDRE to support sustained flight at speeds of Mach 6 to Mach10 directly from conventional runways. Unlike traditional engines that rely on steady combustion, the RDRE harnesses a continuous detonation wave: a supersonic shock front that propagates around a ring-shaped chamber thousands of times per second.

This approach delivers 15-30% higher fuel efficiency and greater thrust in a compact design. The engine operates by injecting fuel, such as jet fuel or hydrocarbon propellants, with a stabilized liquid oxidizer (typically hydrogen peroxide at 70-100% concentration) into the annular chamber, where ignition triggers a self-sustaining detonation wave. Each cycle compresses and ignites fresh mixture, generating immense pressure and thrust while consuming less propellant. With this breakthrough, Venus Aerospace joins other U.S. companies — including Anduril Industries, Hermeus, Castelion, Ursa Major and Kratos Defense & Security Solutions — driving innovation in hypersonics as the nation races to maintain leadership in the global aerospace arena.

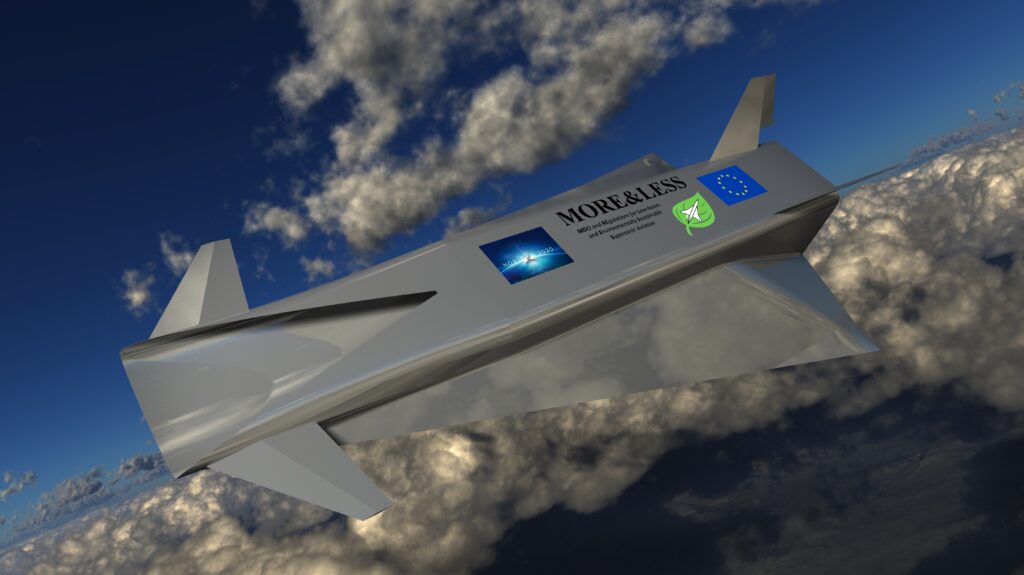

The German Aerospace Center’s (DLR) Institute of Space Propulsion continued its sustainable aviation fuel (SAF) ramjet test campaign within the European More & Less project for emissions testing through multiple test campaigns throughout 2025. Additionally, a big test campaign on rotational detonation combustors (RDCs), a campaign between The French Aerospace Lab (ONERA) and DLR, kept the M11.1 test bench busy from June through August. The tests in this campaign led to a 300 grams per second hot run for two seconds at the end of July after several weeks of successful testing with different configurations and different boundary conditions.The test schedule was completed by two smaller campaigns on new injectors designs at the end of the year.

POLARIS Raumflugzeuge GmbH, a German startup based in Bremen, accomplished its historic in-flight ignition of a linear aerospike rocket engine during a test flight in October of its MIRA II demonstrator. The small company also crossed its 100-flight mark with its four demonstrators in December.

Contributor: Friedolin Strauss

Opener image: Thermal analysis of the HELLO-1 craft at Mach 5 cruise. This is the first in a series of reusable air-breathing vehicles in development by Space Engine Systems of Canada. Credit: SES

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.