Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

The Aeroacoustics Technical Committee addresses the noise produced by the motion of fluids and bodies in the atmosphere and the responses of humans and structures to this noise.

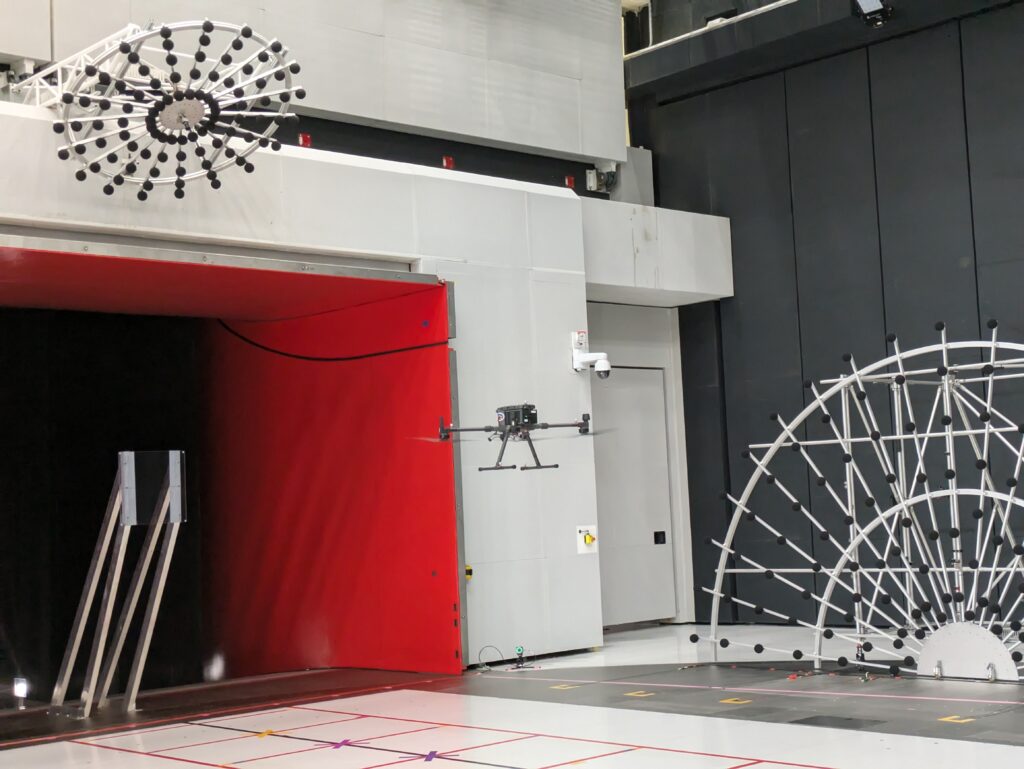

Blue Ridge Research and Consulting, LLC (BRRC) and Archer Aviation in March presented results of November 2024 tests at the NASA Acoustics Technical Working Group meeting. These were the first concurrent measurements of the external community noise and internal cabin noise of an urban air mobility (UAM) vehicle in flight. BRRC applied signal processing techniques to separate individual noise source contributions from the Midnight aircraft’s 12 propellers in flight to understand their complex aeroacoustic interactions.

In early 2025, ATA Engineering Inc., completed a joint project with Merrick-RS&H Joint Venture, Naval Air Warfare Center Aircraft Division, and Hambric Acoustics to redesign an engine test cell to support a higher-thrust engine. They modeled the test cell facility’s acoustic environment and identified a preferred noise control treatment design by utilizing a novel aerovibroacoustic modeling method to characterize the interior acoustic environment of the engine test cell.

In March, the University of California, Davis initiated a research partnership with Seoul National University in South Korea to investigate broadband noise associated with UAM aircraft using high-fidelity computational fluid dynamics simulations, with support from the National Research Foundation of Korea.

In May, Pennsylvania State University and partners at the RTX Technology Research Center, Altair Engineering and Cornerstone Research Group focused on characterizing complex triply periodic minimal surface acoustic liners as part of FAA’s ASCENT Project 79. They sought to identify, understand and account for geometric deviations and manufacturing defects produced via vat photopolymerization additive manufacturing. The team leveraged computed tomography scanning, manual measurements and automated image processing to identify potential problem areas in manufactured specimens.

In June, BRRC collected data during SpaceX Falcon 9 launches at Vandenberg Space Force Base in California with acoustic sensors, accelerometers and weather stations located at some 15 unique sites from within 1 kilometer to over 15 km from the launch pad. These measurements were captured after an extended 12-launch data collection campaign at Cape Canaveral Space Force Station in January. The measurements were conducted in support of ongoing validation of BRRC’s Rocket Noise Simulation Model, RUMBLE, used by the regulatory community to describe the noise environment in communities surrounding rocket facilities.

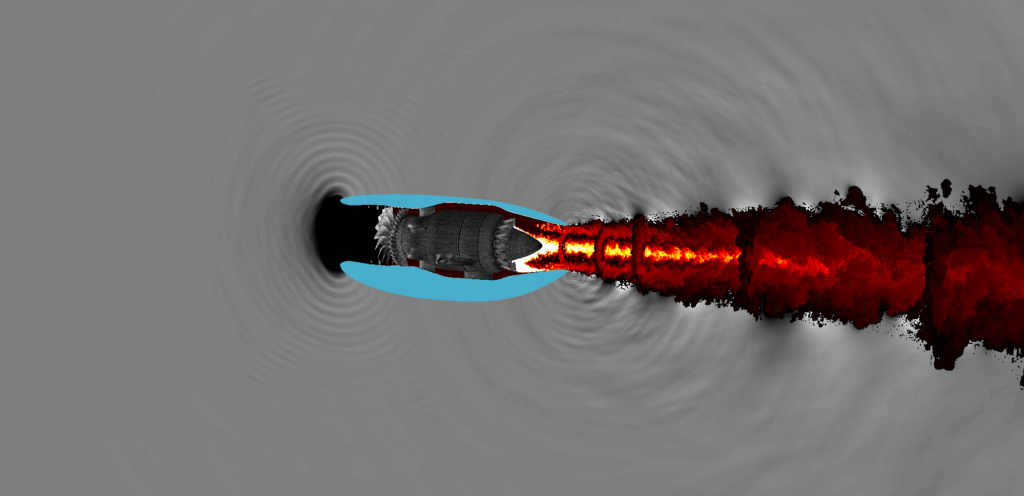

In July, in partnership with Honda R&D, Cadence performed graphics processing unit (GPU)-accelerated large-eddy simulations of the full-scale HondaJet turbofan engine. As a step toward integrated system-level analysis, the model includes the nacelle, bypass duct, OGV, lobe mixer, and the full-wheel fan, low-pressure compressor and turbine. Noise predictions within a few decibels of microphone measurements were obtained in about one day on modest GPU count.

In June and July, NASA’s Commercial Supersonic Technology project conducted a full-scale “dress rehearsal” in the Mojave Desert to prepare for supersonic overflight noise measurements of the X-59 quiet supersonic research aircraft. Using an F-15B aircraft as a stand-in for the X-59, researchers ran through every aspect of the planned test campaign, from flight planning to data collection, to refine their test plan and control room procedures for more orderly X-59 flights.

The Honda Automotive Laboratories of Ohio Wind Tunnel in July awarded aeroacoustics test time under the newly-launched research network convened by The Ohio State University, the Mobility Innovation eXchange in Aero/Acoustics. The National Research Council Canada was invited to conduct wind noise and flight stability testing in the large hemi-anechoic wind tunnel, sized for full-scale ground vehicles.

In August and September, researchers at NASA’s Langley Research Center tested a five-bladed prototype propeller for a tiltrotor UAM vehicle in the 14- by 22-Foot Subsonic Tunnel. This test, supported by the Revolutionary Vertical Lift Technology Project, is to provide modelers and vehicle developers with critical knowledge of the aerodynamic and acoustic behavior of a propeller during the transition modes between vertical and axial forward flight.

Contributors: Juliet Page, Seongkyu Lee, Kevin Disotell, Alexandra Loubeau, Nikolas Zawodny, Parthiv Shah, Jeffrey Mendoza, Guillaume Brès

Opener image: Archer Aviation and Blue Ridge Research and Consulting in 2025 presented results of testing conducted in late 2024. Credit: Archer Aviation

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.