Developing technology for smallsat solar arrays and antennas

By Mark Silver|December 2020

The Spacecraft Structures Technical Committee focuses on the unique challenges associated with the design, analysis, fabrication and testing of spacecraft structures.

As small satellite capabilities continue to grow, the demand for solar arrays and antennas also grows. Through novel methods of deployment, inflation and in-space construction, the spacecraft structures community is developing new technologies to meet these needs.

In January, NASA announced two contract awards for in-space construction on its planned On-orbit Servicing, Assembly, and Manufacturing 1 spacecraft, or OSAM-1, formerly known as Restore-L and scheduled to launch in December 2023. First, Maxar Technologies of Colorado will develop a robotic arm to build a Ka-band antenna in space. Second, Tethers Unlimited of Washington will develop technology to manufacture a 10-meter composite beam.

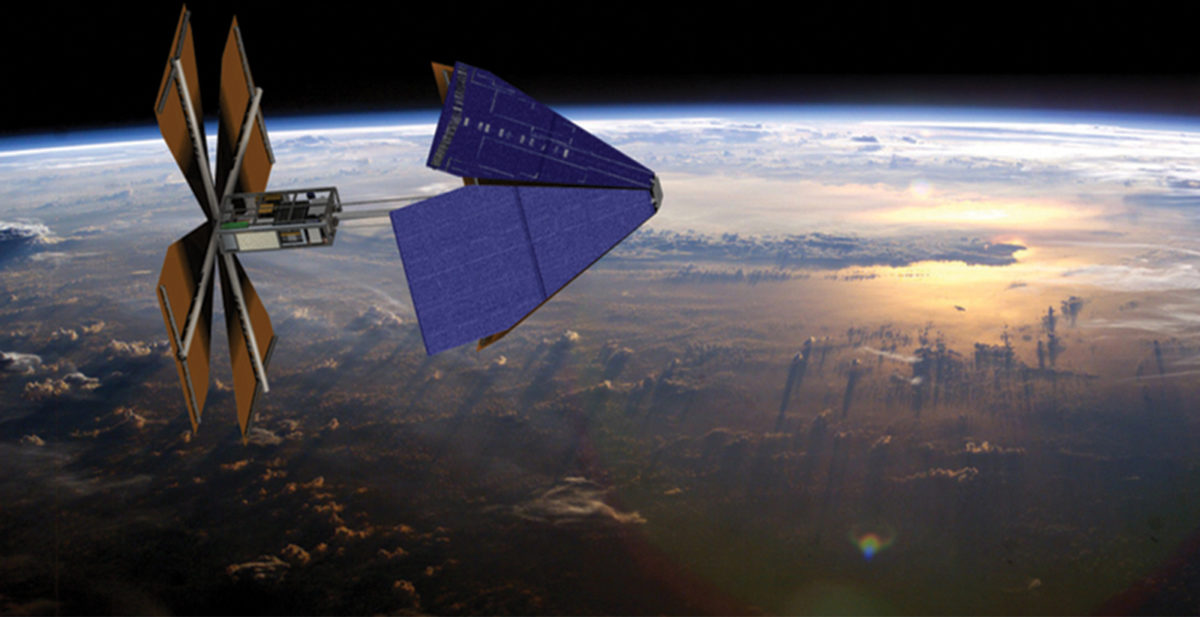

In February, Colorado-based Blue Canyon Technologies and Florida-based Made in Space announced their partnership in building NASA’s OSAM-2 satellite. The satellite will demonstrate the in-space manufacturing of two, 10-meter booms on opposite sides of OSAM-2 to support solar arrays. As the booms are 3D-printed in space, the solar arrays will unfurl in tandem. These solar arrays will be able to generate up to five times more power than traditional solar panels on similar-sized spacecraft, NASA says. This technology is being developed to help expand solar power generation capabilities for NASA’s Artemis program, which aims to put humans back on the moon by 2024 and on Mars.

Roccor Inc. of Colorado completed radio frequency testing of its Link 16 deployable antenna in May. Link 16 is the tactical data link used by NATO aircraft, ships and ground forces. Viasat is building the constellation of satellites that will carry the antenna as part of the U.S. Air Force Research Lab’s XVI program. Viasat’s first XVI satellite is scheduled to launch next year. Roccor’s design is a 2-meter-long, helical, L-band antenna that deploys from a 20-by-10-by-10-centimeter volume using a high-strain composite deployable mechanism.

In August, NeXolve Holding Co. completed a design review of the Lightweight Integrated Solar Array and Transceiver with NASA’s Marshall Space Flight Center in Alabama. The LISA-T deploys from a 10-by-10-by-10-centimeter volume and can generate up to 340 watts of power with simultaneous communication in the Ka-band through its antenna. This review included results from microgravity deployment experiments of the LISA-T performed earlier in the year.

Also in August, Airbus finished ground deployment testing of its 12.3-meter-long C-band Synthetic Aperture Radar antenna for the European Space Agency’s Copernicus Sentinel-1C satellite. ESA will use the Sentinel-1C SAR to map the Earth’s surface; collect data on the arctic, marine and forest environments; and help manage humanitarian relief and disasters. During the tests, Airbus measured the mechanical properties of the antenna after deployment, including planarity and shape accuracy. These measurements are critical to predicting performance of the SAR once on orbit. The next step for SAR acceptance is full radio frequency functional testing including the deployed antenna and electronic subsystems.

Contributor: Jim Moore