Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

The Meshing, Visualization, and Computational Environments Technical Committee explores the application of computer science to preprocessing, postprocessing, and infrastructure in support of computational simulation in the aerospace community.

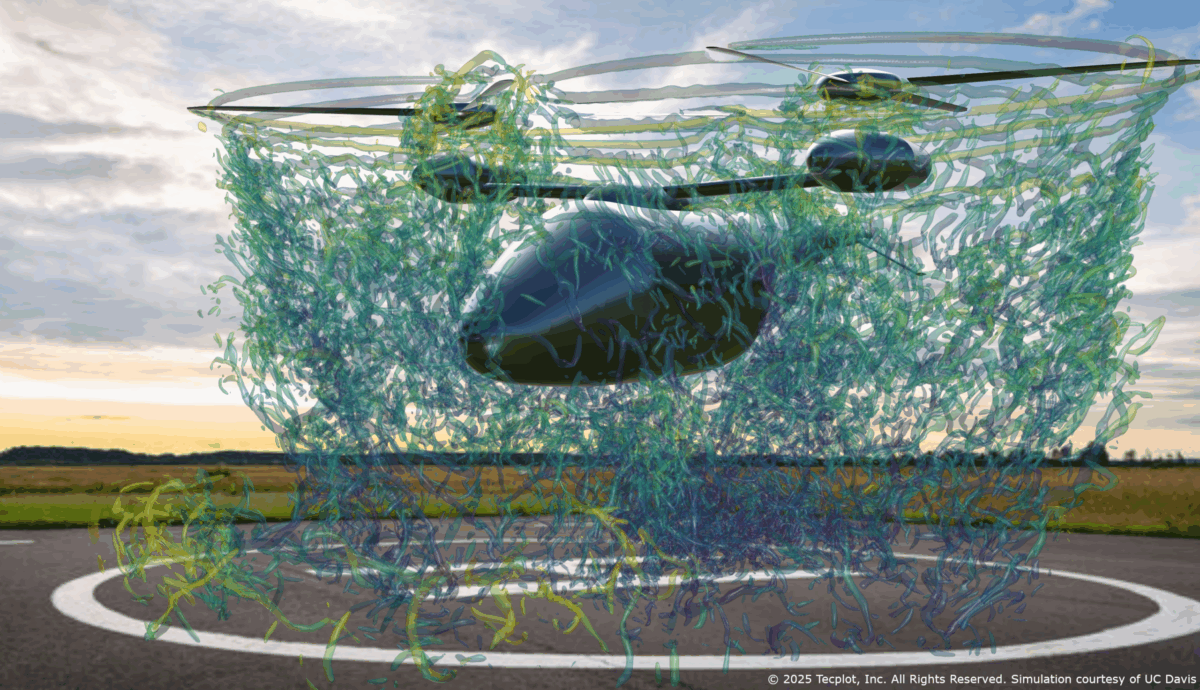

Most computer aided engineering (CAE) visualization tools used in aerospace rely on OpenGL, an application programming interface (API) dating to the early 1990s. In 2025, Tecplot developed a next-generation graphics engine designed to meet the increasing demands of aerospace simulations. This engine leverages the modern API Vulkan to deliver faster rendering, more efficient memory utilization and advanced visualization techniques. For engineers working with complex datasets, Vulkan-based Tecplot 360 and FieldView versions have demonstrated performance improvements of up to 200 times. FieldView’s updated engine extends visualization fidelity through Physically Based Rendering (PBR) and Image-Based Lighting (IBL) to more accurately represent real-world material behavior that not only enhances visual realism but also improves the speed and scalability of postprocessing workflows.

There was a major leap toward graphics processing unit (GPU)-native adaptive mesh refinement (AMR) for aerospace computational fluid dynamics (CFD), with key efforts to adopt such frameworks to high-fidelity solvers. These approaches share focus on end-to-end GPU execution, block-structured refinement and multiphysics support for chemically-reactive flows. By running entirely on the GPU, these solvers eliminate the central processing unit (CPU)-GPU data transfer bottleneck. Octree or patch-based meshes allow for efficient scaling to multi-GPU systems.

The year also saw major improvements in the underlying input/output (I/O) architecture for supporting aerospace-scale simulations. GPU-aware I/O enhancements in ADIOS 2 allow direct writes and reads from GPU memory, bypassing expensive CPU staging. These are paired with on-GPU compression and smart buffering strategies, including node-local burst buffers and significant standards differences (SSD) tiers to reduce I/O latency and storage footprint.

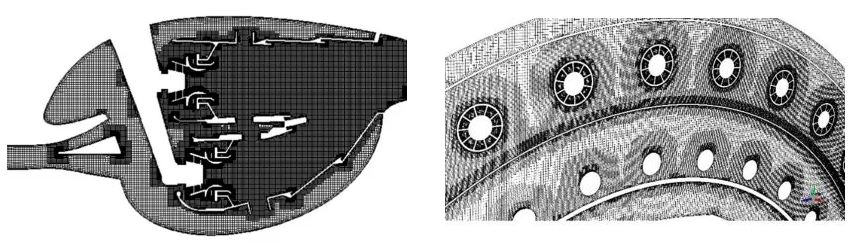

In February, Ansys Fluent introduced rapid octree meshing, which generates volume meshes first prior to projecting them onto geometry, reducing or eliminating surface-mesh preparation and the related computer-aided design cleanup. Massive parallelism is utilized to produce billion-cell meshes in under 30 minutes on thousands of CPU cores with near-linear scaling. For example, a 1-billion-cell combustor mesh was built in 28 minutes on 1,536 cores and solved on 48 NVIDIA L40 GPUs in 28 hours, whereas a billion-cell aircraft large eddy simulation (LES) was meshed in under half an hour and solved in 30 hours on 40 GPUs. These improvements dramatically reduce turnaround time, enabling routine use of high-fidelity LES/DES and combustion simulations.

The aerospace/high performance computing community also made substantial progress in visualization pipelines, particularly via the Catalyst-ADIOS 2 framework. Simulation codes can perform lightweight data reduction in situ and then send a much smaller, processed dataset in transit to dedicated visualization nodes without halting or delaying the solver. This hybrid method strikes a balance by maintaining the responsiveness and immediacy of in situ workflows while avoiding the bandwidth bottlenecks of full-data streaming allowing users to monitor ongoing simulations, spot issues, and make corrections earlier in the workflow.

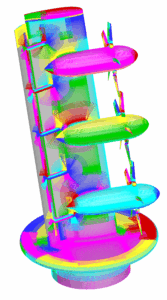

In August, NASA’s Ames Research Center announced recent advances in the overset structured mesh generation toolset EPOGS and the rotor blade mesh generation tool BladeGen, which together enabled rapid generation of meshes and input files for flow and aerodynamic loads computation in applications involving relative-motion components. The Tiltwing Test Rig case was completed in about 1.5 days, including repair time, whereas the VAERA Drone case was completed in under one hour with no repair needed.

Two freely available geometric modeling tools — the Vehicle Sketch Pad (OpenVSP) and the Engineering Sketch Pad (ESP) — were combined in January to give the designers more power during the conceptual design phase. OpenVSP’s strengths include a graphical user interface for the rapid creation of aerospace vehicles by combining wing-like and fuselage-like bodies. ESP’s strengths include a robust set of tools for combining models from various sources into a geometric model to be analyzed by multidisciplinary analysis tools. Parts retain their sensitivities, allowing for analysis of the impact of design parameters on objective functions such as lift and drag.

Contributors: Yves-Marie Lefebvre, Mohammed Kamel, John Francis Dannenhoffer III, and William M. Chan

Opener image: A simulation post-processed with the Vulkan-based version of FieldView, released in December 2025, that leverages physically-based rendering (PBR), image-based lighting (IBL), and order-independent transparency (OIT). Credit: Tecplot Inc.

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.