Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

The work of the Adaptive Structures Technical Committee enables aircraft and spacecraft to adapt to changing environmental conditions and mission objectives.

This year, multiple efforts across the community addressed shape-memory materials. A team at Arizona State University made significant progress in developing shape-memory polymer, or SMP, composites with self-sensing and self-healing capabilities. In July, the team demonstrated Joule heating in an SMP glass fiber composite by implementing a conductive indium-tin oxide coating. In October, the team combined the ITO-enhanced glass fiber composites with stress-responsive mechanophores to develop an SMP composite that acted as its own sensor. Developed with U.S. Office of Naval Research funding, this novel material will contribute to stronger, safer and more capable aerospace structures.

Regarding shape-memory alloys, students and faculty at Texas A&M University continued their collaboration with NASA’s Langley Research Center in Virginia. In November, the team began construction of a wind tunnel model of a structural component formed from shape-memory alloys designed to significantly reduce noise generated by the slat-wing interface. The planned testing will involve acoustic wind tunnel facilities and a custom-built scanning beamforming array to allow researchers to “see” noise reductions from these adaptive structures.

Structural adaptivity without the use of shape-memory materials also showed new promise early in the year. In January, researchers from the U.S. Army Research Laboratory in Maryland flight tested a novel wing-strike alleviation mechanism that combined classical components with a buckling strip, enabling both wings to sweep back symmetrically when either wing impacted an object. For the flight test, a small drone was flown into fixed poles, resulting in catastrophic failure of unmodified wings. When the wing strike alleviation mechanism was incorporated, both wings rotated to mitigate impact effects and then returned to their original position after clearing the obstacle, enabling recovery and continued flight.

In March, a patent was granted to researchers from Delft University of Technology in the Netherlands for a system that passively changed the camber of helicopter blades based on the magnitude of the centrifugal force, which changes with rotor speed. The system allows blades to assume the best possible shape for various flight conditions without requiring additional energy.

In April, the Army Research Laboratory supported researchers from Texas A&M University, the University of Michigan and NextGen Aeronautics of California in demonstrating a novel automated and multidisciplinary design framework for the first time. Given a set of mission-level requirements — such as mission segments and vehicle speeds — the framework explored the design space of morphing unoccupied aerial vehicles with computational fluid dynamics data to quantify the aerodynamic performance, vehicle maneuverability and agility capabilities, design space decomposition to rank adaptivity schemes, and finite element analyses incorporating pressure fields from the CFD to quantify the weight penalties of morphing. The framework was effective in enabling designers to answer two specific questions: “Does morphing provide a significant enhancement in performance?” and “What morphing scheme is most advantageous?”

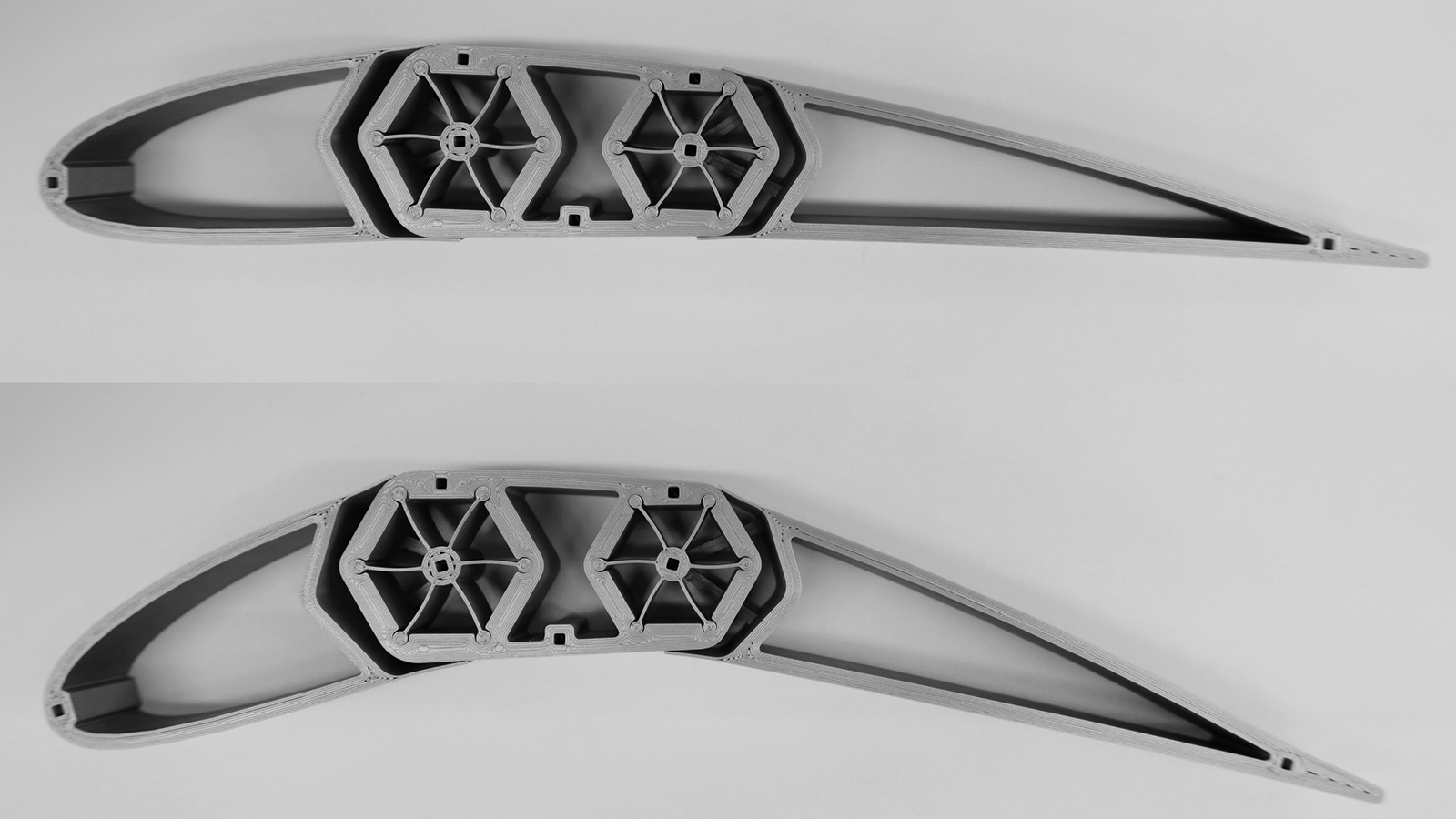

In October, the Army Research Laboratory hosted researchers from Johns Hopkins University for wind tunnel testing of a new bistable mechanism for airfoil leading- and trailing-edge morphing. The mechanism consists of rotary elements that rotate a central element by up to 40 degrees. Such a mechanism enabled the deployment and retraction of both leading-edge slats and trailing-edge flaps for changing wing performance across diverse flight conditions.

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.