Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

The push to expand Earth’s economy into space has prompted NASA to pump millions of dollars into the old idea of establishing propellant depots in Earth orbit for satellites or passenger transports and cargo tugs headed for deep space. Jon Kelvey looks at the reasons for the renewed interest — and the hurdles ahead.

William Notardonato is an expert in the cold: minus 252.87 degrees Celsius cold, to be exact. A 30-year veteran of NASA, Notardonato spent his career investigating in-space storage and handling of liquid hydrogen. Combined with liquid oxygen, these cryogenics are of course best known as common propellants for space launch vehicles, but if large volumes of them could be stored in tanks in space, rockets could swing by these depots in the vicinity of Earth, take on propellant and carry passengers and cargo into deep space, whether to the moon, Mars, an asteroid or a human outpost.

“We ended up doing a lot of things with liquid hydrogen [in the lab] that nobody’s ever done before,” Notardonato says. “Keeping it in a zero-loss storage condition, doing zero-loss chill downs, no vent transfers.”

One thing he didn’t do? A space experiment to verify that these techniques work as expected in free fall, also known as microgravity. So when Notardonato left NASA in 2019, he decided to pursue the goals that got away from him as a public servant, founding Eta Space with “a bunch of ex-NASA guys with a lot of good ideas.”

He won’t try to fuel anything up for deep space right away. Instead, Eta Space plans to launch its LOXSAT 1 technology demonstrator to low-Earth orbit in 2024. The 150-kilogram satellite mainly consisting of a spherical storage tank and a cubic radiator will demonstrate techniques essential to long-term storage of cryogenics. First up will be proving the satellite can store liquid oxygen with zero boil-off over its nine-month mission. Eta Space will also conduct pressurization and depressurization tests, practice zero propellant loss chill downs of fluid transfer components and attempt to transfer propellant between LOXSAT’s internal tanks. NASA is on board, having awarded Eta Space $27 million in Tipping Point program funding for the LOXSAT demonstrator in 2020.

“A lot of this stuff we have done on the ground,” Notardonato says. “It’s really proving it now in a microgravity environment, which has never been done before.”

Eta Space won’t attempt to dock the LOXSAT demonstrator with another spacecraft, but assuming a successful mission, the company plans to launch Cryo-Dock, a larger version of LOXSAT 1 at 20,000 kg, as the first commercial propellant depot offering liquid hydrogen and liquid oxygen to spacecraft ranging from rocket upper stages heading for deep space to orbital transfer vehicles conducting satellite servicing or debris removal. Eventually, Notordonato says, Cryo-Dock could even refuel shuttles and landers heading toward the moon.

Staging propellant in space or refueling on orbit isn’t a new idea, but it’s a concept enjoying a moment. In addition to Eta Space, NASA and SpaceX are depending on a lunar lander variant of SpaceX’s Starship vehicle that is designed to require refueling with cryogenic methane and liquid oxygen in Earth orbit shortly after launch, a technique that SpaceX must prove as part of an uncrewed lunar landing demonstration with Starship before the first flight with astronauts. And in the satellite domain, the idea of propellant depots is gaining steam, with at least one operational facility offering noncryogenic propellants already. In the long term, proponents talk up the possibility of creating a sustainable cislunar economy as a foothold toward utilizing resources on the moon — or asteroids, or Mars — to create fuel where it’s cheapest: outside Earth’s steep gravity well.

It’s enough to make one wonder just why depots are having a moment now, and not 10, 20 or 30 years ago. The answers are political and technical, with politics often dictating the pace of innovation.

Refueling research

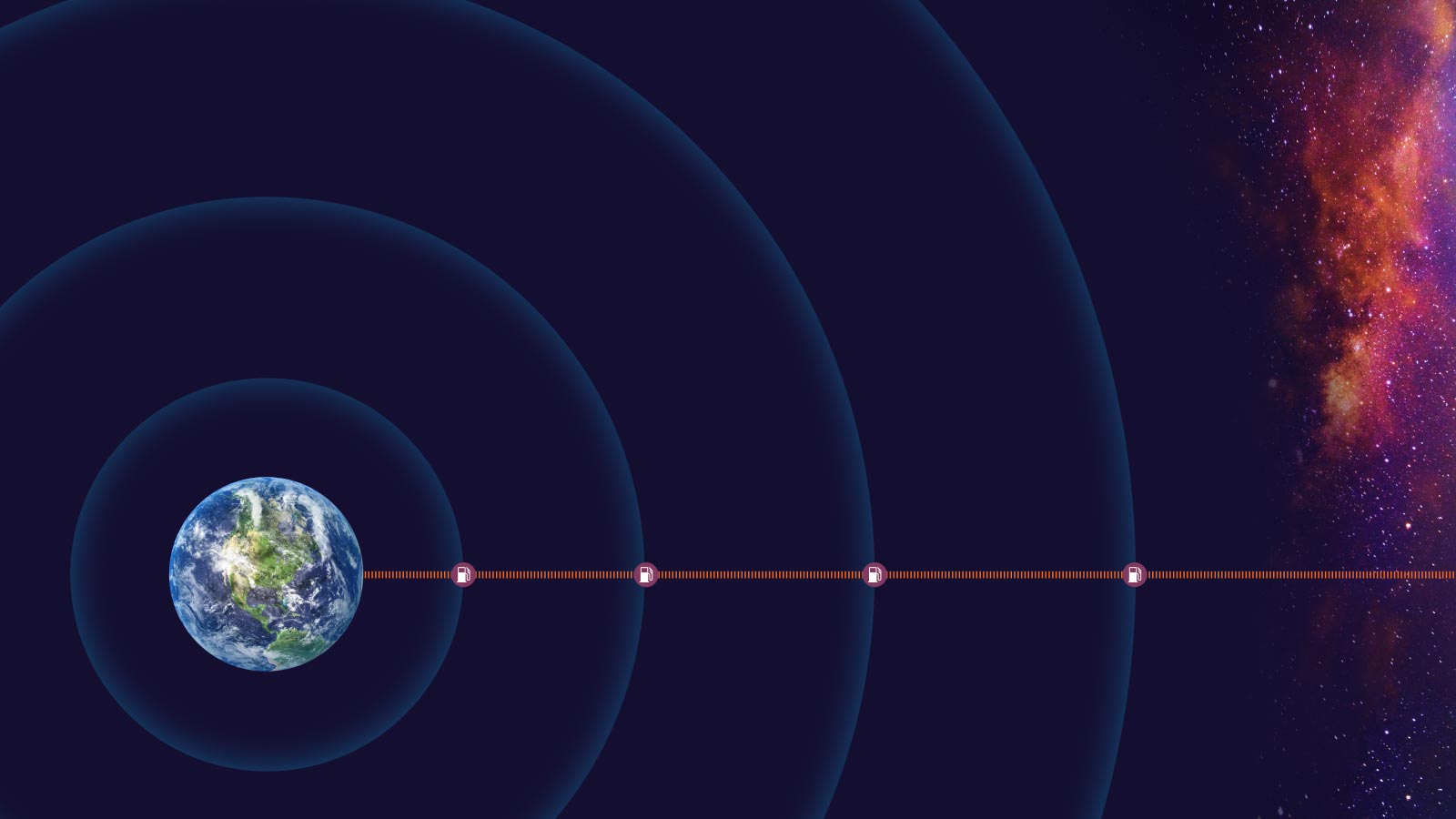

For rocket builders, depots could be the answer to one of their greatest conundrums: how to store as much fuel as possible without making a rocket too heavy to escape Earth’s gravity well. Refueling a rocket’s upper stage from an orbital depot means you don’t have to carry everything with you in one go.

“Depots allow you to address bigger missions with smaller vehicles,” says Jonathan Goff, the owner of aerospace consulting firm Starbright Engineering. And smaller, cheaper vehicles can make for a higher flight rate, “which is kind of key for getting the cost down.” Depots can also enable entirely new operations and designs, such as reusable space stages that, for instance, could shuttle back and forth between Earth orbit and lunar orbit without ever returning to Earth.

Eta Space is the smallest of the four companies to receive 2020 Tipping Point funding from NASA, with Lockheed Martin receiving $89.7 million, United Launch Alliance $86.2 million and SpaceX $53.2 million. Lockheed Martin plans to demonstrate liquid hydrogen management in space. ULA is looking into keeping Vulcan Centaur upper stages in orbit after each launch and using them as deep space tugs, and so it plans to explore long-term storage and internal transfer of cryogenics within a Vulcan Centaur upper stage. And SpaceX would transfer 10 metric tons of liquid oxygen between tanks aboard a Starship spacecraft in Earth orbit, as though it were fueling up the Starship that will head toward lunar orbit and rendezvous with an Orion capsule to take two astronauts to the surface for NASA’s Artemis III mission, currently scheduled for 2025.

And propellant depots are not just for rockets and deep space operations. The concept is further along in the satellite world: Last year, Colorado-based Orbit Fab launched its Tanker-001 Tenzing, the first operational propellant depot for defense satellites. Tenzing carries high-test peroxide, not more difficult to store than cryogenic propellant, although Orbit Fab co-founder Jeremy Schiel says the company might consider cryogenic depots in the future. Refueling satellites can not only extend their lives and make deorbiting them easier, it can also free operators to maneuver as their needs dictate, rather than their fuel budget, he says.

“Once you start refueling, it changes the paradigm,” he says. “The hurdle that’s being overcome in the next three to five years is just the 60 years of history of not having fuel on orbit.”

Historical challenges

Each era of spaceflight has had its own circumstances that turned NASA’s attention away from orbital fueling strategies. In the Apollo era, America’s race to beat the Soviets to the moon led NASA to adopt a mission architecture in which a single rocket would boost the astronauts, their lander and command module toward lunar orbit, where the command module would dispatch the lander to the surface. However, Wernher von Braun and others at NASA’s Marshall Space Flight Center had favored the Earth Orbit Rendezvous concept, in which two spacecraft would have been launched by two rockets, one carrying the Apollo astronauts and the other carrying fuel as a tanker, for rendezvous and assembly in low-Earth orbit. Ultimately, von Braun and NASA decided that the Lunar Orbit Rendezvous approach was necessary to make Kennedy’s famous deadline.

“If they had done the tanker mode, they wouldn’t have needed as big of a vehicle; they could have gotten away with the Saturn 1,” Goff says. That could have allowed for a higher flight rate and a more sustainable program, since “the technology would have been on the shelf where they could have done follow-on missions easier, even if they had shut down the capabilities.”

As it happened, the Nixon administration decided to truncate Apollo after Apollo 17, and by the late 1970s, NASA transitioned into the space shuttle era. With NASA’s focus on orbital spaceflight rather than deep space exploration, crafting fuel depots to unlock human exploration of deep space simply was not a priority, a trend that continued all the way through the early 2000s and the era of the International Space Station.

For a time during the Obama administration, it looked to Goff like depots might be back on the table. At the time, he was CEO of Altius Space Machines, a maker of robotic arms, propellant valves and other space technologies. In 2010, the new administration canceled the Bush-era Constellation program and its development of a giant moon rocket in favor of fostering development of privately owned rockets by the nascent commercial space launch industry for transporting astronauts to and from ISS. Those rockets might eventually also boost astronauts and equipment to the moon or Mars, Goff thought, an approach that would potentially lend itself to positioning one or more fuel depots in orbit for refueling.

But he did not anticipate the political backlash.

“We really set up a dynamic where it was seen as depots versus big NASA rockets,” Goff says. “And there are congressional people who care about the jobs that come from big NASA rockets and their districts.”

Members of Congress led by Republican Sen. Richard Shelby of Alabama and Democratic Sen. Bill Nelson of Florida — now NASA administrator — still wanted a line of big, expendable NASA rockets, and they got it in the Space Launch System program. Once development of SLS began in 2011, Goff says, NASA and big contractors alike wanted nothing to do with propellant depot concepts.

“It was just verboten,” he says. “If you said anything depot related, you were the enemy.”

So one answer to the question of why orbital fueling is gaining traction now could be that much of the political pressure of the 2010s has now lifted. “SLS is about to fly, [SpaceX’s] Starship is about to fly,” Goff says. “Almost all the people in the Senate that are behind SLS have retired.”

But that easing of pressure is not the only answer. The commercial space industry has heated up to the point where there’s pent-up demand for services like satellite refueling. When Orbit Fab first looked at that market four years ago, “there were eight companies looking at doing satellite servicing,” Schiel says. Now, globally, there are over 100 companies, including Northrop Grumman and its Mission Extension Vehicles and tug services like Momentous of California.

“We started at the perfect time when servicing was starting,” Schiel adds.

Another reason the concepts are having a moment is also related to NASA and SLS.

“Why now is because of Artemis,” says space consultant Laura Forczyk, author of “Becoming Off-Worldly: Learning from Astronauts to Prepare for Your Spaceflight Journey.” When NASA selected a variant of SpaceX’s Starship as the Human Landing System for the Artemis III mission, the agency committed to a mission architecture requiring as many as 16 Starship launches to fill a “tanker” version of Starship with liquid methane and liquid oxygen. That tanker Starship would then transfer fuel to the HLS Starship in Earth orbit.

A Starship prototype has yet to fly higher than 10 kilometers, and never attached to a Super Heavy booster needed to send it to orbit, but “NASA now is relying on this technology to be able to get humans to the surface of the moon,” Forczyk adds.

Making it work

And of course, there are also technological challenges remaining.

“If you’ve got a cryogenic propulsion system, there’s a few key technologies that don’t exist yet,” says Jason Adam, who manages NASA’s cryogenic fluids management portfolio project office. His team manages the Tipping Point programs, including preparations for Eta Space’s demonstration mission, and also conducts research focused on the challenges of in-space cryogenic fueling.

The first challenge is active cooling. Insulation can only do so much when liquid hydrogen boils at just over minus 253.15 C, so if you had a camera inside a rocket on the launch pad, “it would be sitting there boiling.” That problem doesn’t go away in space just because convection is lost as a heat transfer mechanism, and any depot designed to store cryogenic fuel for long durations will need to minimize boil-off. Adam’s team is developing a cryocooler technology to solve those issues.

“Think of it as a refrigerator motor that would go on a rocket,” he says. The goal is to keep the liquid hydrogen and liquid oxygen stable, “or what we call a zero-boil-off condition.”

Cryocooler technologies have existed for a while, with much of the development driven by NASA science missions like the Hubble Space Telescope, according to Notardonato, but “the cryocooler technology was not as advanced in the 1990s” compared with today.

The second challenge, and one that all of the Tipping Point companies must contend with, is managing propellant in microgravity. You have a depot with a tank half full of liquid hydrogen and a spacecraft you want to transfer it to: Where is this hydrogen?

“On Earth, the hydrogen will be at the bottom of the tank because we’re in 1G,” Adam says. But in free fall, “where the heck is the hydrogen? It could be anywhere.”

It’s not yet clear if techniques long used to manage noncryogenic fluids in microgravity, such as inflatable bladders and internal storage tank vanes and baffles to make use of surface tension, will work for cryogenics, but Adam said the various Tipping Point programs aim to explore the possibilities.

Meanwhile, NASA engineers at Marshall Space Flight Center are working on yet another challenge: keeping the propellants contained.

“If you’ve ever had any experience in cryo systems, the one thing that you’ll know is all cryo systems leak,” Adam says.

A small amount of leakage isn’t a big deal from a rocket that’s delivering a payload in a matter of minutes and is then done. But for a mission to Mars or a liquid hydrogen propellant depot, getting cryogenics sealed in tightly is important.

And NASA’s making progress: “We’re doing some ground tests right now on some large cryogenic valves that would improve internal leakage between two and three orders of magnitude over the state of the art,” Adam says.

He’s fairly confident that NASA’s research, along with the Tipping Point programs, will solve a lot of the problems with cryogenic fluid management, though certainly not all of them. “Cryo is pretty crazy stuff. I’ve been around long enough to know anything could happen.”

The future with depots

It’s true, anything could happen with cryogenics, and with space generally. But what if good things happen? What might success look like?

For Orbit Fab, it would mean launching its Tanker-002 later this year or early next year, a geostationary gas station carrying 90 kg of hydrazine, and getting satellite operators used to a whole new way of thinking about fueling.

“Fuel today is a capital expense,” Schiel says. “You put it all up, and once it’s done, it’s done.”

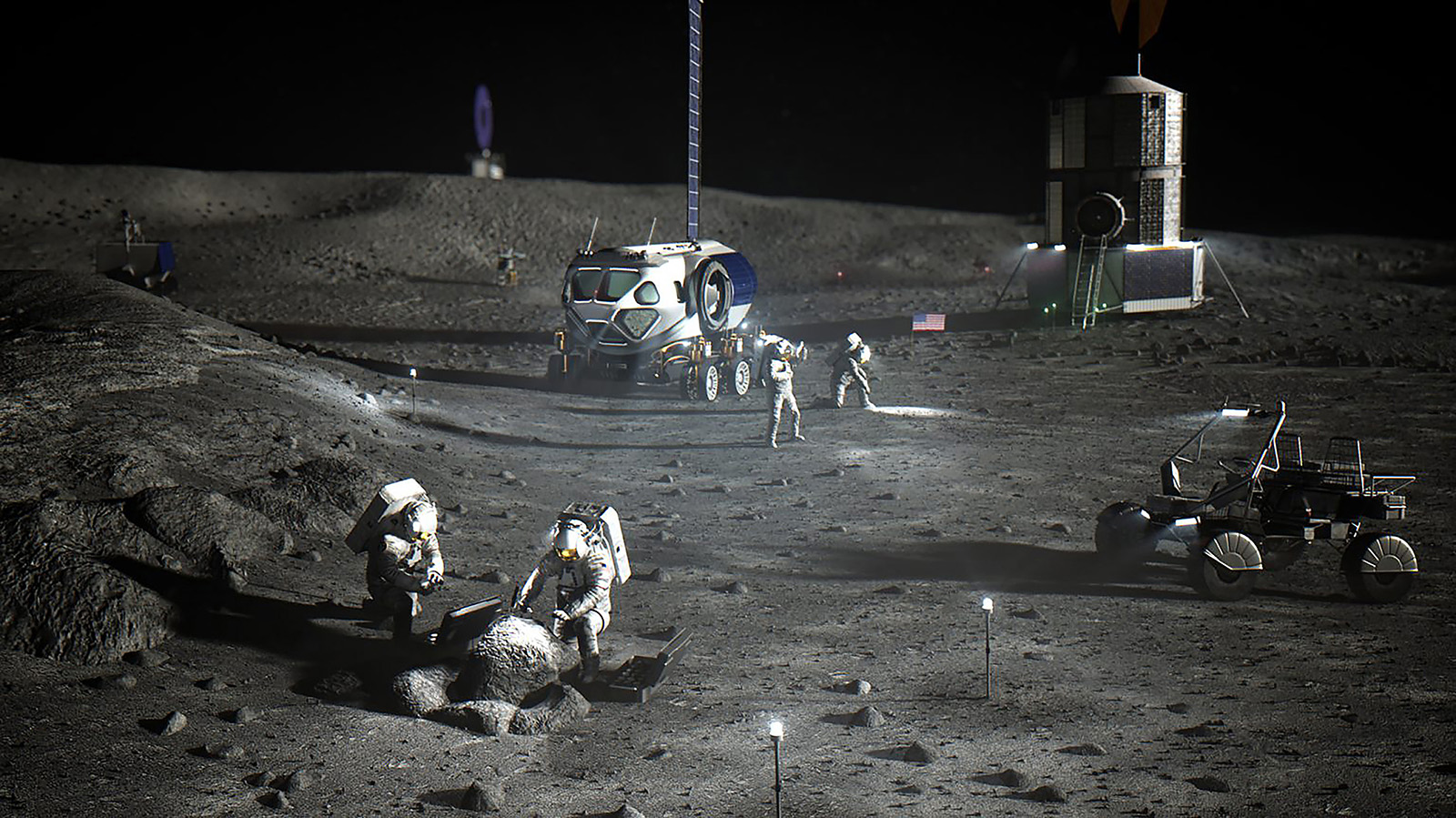

For Eta Space, success would mean a LOXSAT mission that proves the technology for the first Cryo-Dock and, eventually, propellant depots on the surface of the moon to support NASA’s Artemis program — assuming SpaceX solves its cryogenic fluid transfer puzzle necessary to land astronauts.

At that point, Forczyk says, NASA and companies including Eta Space might start looking at manufacturing propellants from lunar resources and forgo launching them from Earth altogether.

The idea is to “leapfrog to the point where you’re making that fuel in situ somewhere,” she says. “The moon is our closest neighbor, and it does have all the materials that we need for fuel for propellants.”

Government and industry might then consider building up a strategic propellant reserve on the moon, as ULA CEO Tony Bruno suggested to the National Space Council in 2020, which Forczyk calls “an excellent way to kick-start a cislunar economy.”

That’s getting maybe a decade ahead of the story right now, she notes, and the technical challenges and economic and political realities could change the pace of the plot. But “it seems like we’re on the cusp of it beginning,” Forczyk says. “Some version of orbital refueling is happening, is going to happen. Whether all of the promises of orbital refueling come into play, I don’t think anyone can say.”

“Fuel today is a capital expense. You put it all up, and once it’s done, it’s done.”

Jeremy Schiel, Orbit Fab

About jon kelvey

Jon previously covered space for The Independent in the U.K. His work has appeared in Air and Space Smithsonian, Slate and the Washington Post. He is based in Maryland.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.