Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

A decade ago, NASA commissioned some of the nation’s top aerospace companies to build a series of expendable rockets to take American astronauts to the moon and someday to Mars. SpaceX started a similar project years after NASA but has spent vastly fewer tax dollars. Now both are racing to the launch pad. Cat Hofacker set out to find out why NASA shows no signs of wavering on the Space Launch System.

When Virginia Barnes retired from Boeing in 2015, her colleagues gave her four poster board-sized tickets resembling the giant checks given to TV game show winners. The golden cardboard slabs were printed with these words: “ADMIT ONE, SLS First Launch,” at the time thought to be just a few years off.

Barnes is still waiting to cash in her prize, but perhaps not for much longer. The uncrewed inaugural launch of the Space Launch System, the expendable rockets that will deliver astronauts to lunar orbit ahead of surface landings, might now be just months away.

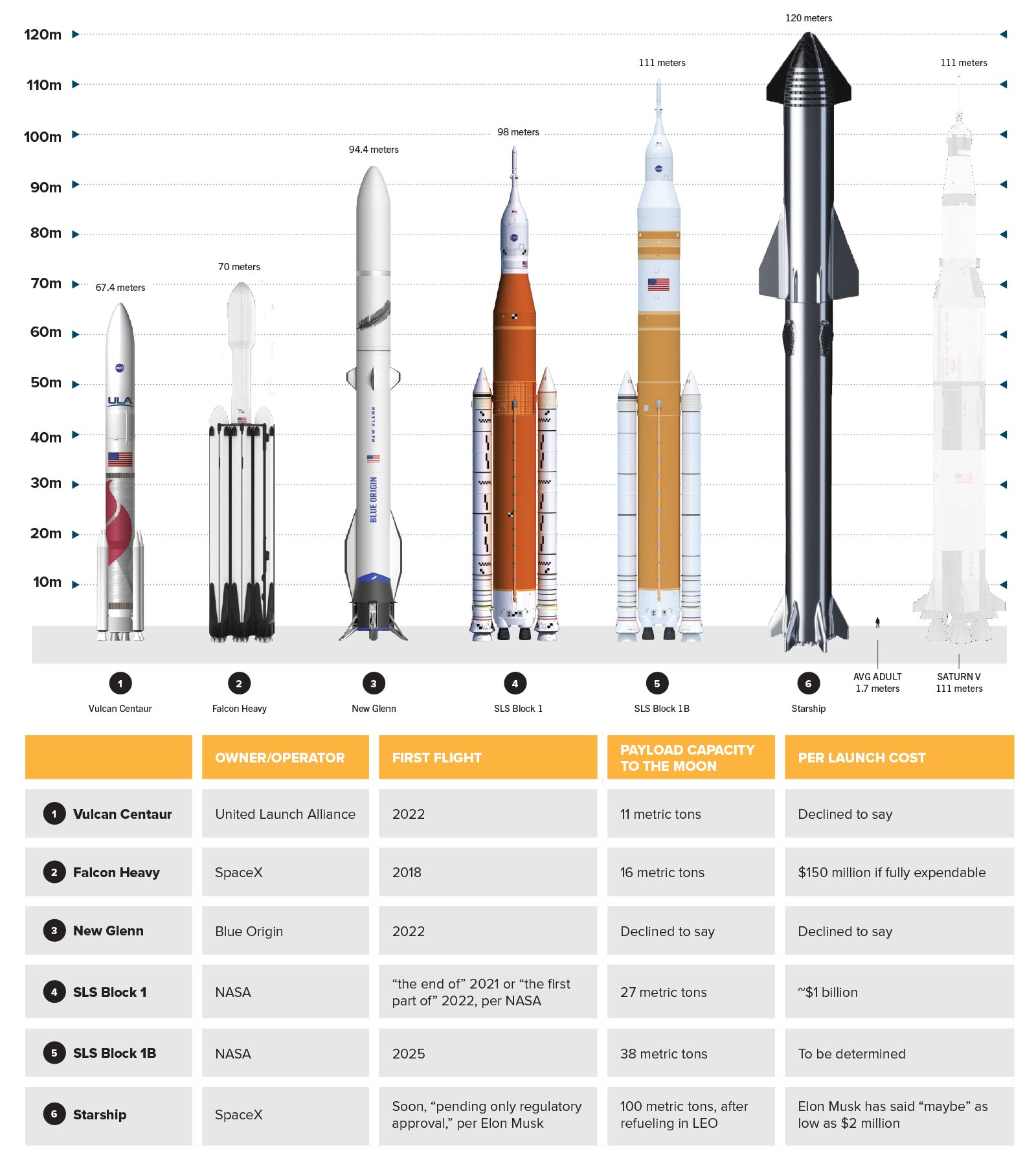

The launch will be a big moment for NASA, but perhaps not a triumphant one, even if all goes as planned. The launch is four years overdue, and the program’s anticipated cost has doubled to $20 billion. That figure doesn’t include the $18 billion spent developing the Orion crew capsules that would fly atop the rockets, plus the necessary upgrades at the launch pad at NASA’s Kennedy Space Center in Florida. The delays and cost overruns have led to hard questions from outside analysts over whether NASA, in fact, still needs its own fleet of deep space rockets, given the number of companies developing their own heavy-lift vehicles, including SpaceX. Its Starship design is the farthest ahead and most comparable to SLS in terms of throw weight, and the first Starship could reach space about the time the first SLS does.

“Maybe three to four years ago, SLS filled a hole in the market,” says Jordan Noone, co-founder and partner at Embedded Ventures, a California venture capital firm that funds innovative space infrastructure startups. “Now that hole is being rapidly closed in the commercial sector” because companies including SpaceX have drastically reduced the cost of launch, freeing startups to focus on markets including optical comms.

NASA shows no signs of second thoughts, if it is having any. Why is that? Casey Dreier, the senior policy analyst at the California nonprofit The Planetary Society, has a theory: SLS “is the essence of the agency, so it has a high symbolic value,” he says. “It has to succeed.”

This account of NASA’s unwavering support of the long-delayed and over-budget SLS is based on reviews of agency planning documents, reports from the NASA Office of Inspector General and the congressional Government Accountability Office, as well as interviews with analysts, space industry executives and a half-dozen current and former leaders from Boeing and NASA.

A monster rocket

It was March 2019, and then-NASA Administrator Jim Bridenstine was testifying in front of the U.S. Senate Commerce Committee. The committee backed SLS, but it was getting harder and harder to do so. The inaugural SLS flight to send an unoccupied Orion capsule around the moon was in danger of slipping to the right — again. Committee chair Sen. Roger Wicker, R-Miss., in whose state NASA tests the majority of the SLS hardware, pressed Bridenstine about NASA’s efforts to keep the June 2020 target date.

Bridenstine paused for the barest second. Then, speaking slowly and appearing to take great care in choosing his words, he said NASA was studying whether two commercial heavy-lifters might instead conduct the mission. One rocket, such as a Delta IV Heavy from United Launch Alliance, would blast the 22.7-metric-ton combination of Orion crew module and service module that weighs roughly the same as two orcas to low-Earth orbit. Another rocket, perhaps a SpaceX Falcon Heavy, would launch the upper stage that would set the capsule on a trajectory to lunar orbit.

The proverbial Washington walk-back quickly ensued. The day after the hearing, NASA posted the text of an email from Bridenstine to the NASA workforce on NASA.gov, which emphasized that the agency “is committed to building and flying the SLS” in part because “launching two heavy-lift rockets to get Orion to the Moon is not optimum or sustainable.” The message seemed to be: Please don’t misconstrue multiple commercial rockets as a possible long-term alternative to SLS.

The exchange illustrates the two central questions about the necessity of SLS. The first is philosophical: What is NASA’s unique role that can’t be filled by space companies designing and building their own rockets with their own dollars? The second is technical: Why a big rocket?

The answers lie in the chain of events that led to the creation of SLS.

February 2010 was a gloomy month for those inside and outside of NASA who believed that, no matter what concepts might be percolating in the private sector, NASA needed its own fleet of launch vehicles to ensure American leadership in human space exploration. The first disappointment was that NASA’s 2011 budget request proposed zeroing, rather than replacing, the George W. Bush administration’s Constellation moon program and its in-development Ares rockets. These would have blasted crew capsules and landers to Earth orbit to prepare for lunar surface missions.

The second disappointment was less surprising. The request reflected the long-standing plan to retire the space shuttle fleet, meaning that the United States would need to buy seats on Russian Soyuz capsules to get astronauts to and from the International Space Station. For the longer term, the budget proposed funding the development of privately owned spacecraft that would transport NASA astronauts to ISS under contracts.

When the request landed, the behind-the-scenes fuming began. Space executives and some U.S. lawmakers were deeply unhappy that the 2011 budget request had simply ended Constellation. Among those upset was former astronaut Charlie Bolden, the NASA administrator at the time. The White House’s Office of Management and Budget had overruled the agency’s original budget submission.

“In that budget, the only thing about human spaceflight that included NASA was production of a LOX [liquid oxygen] kerosene or LOX-rocket propellant engine” that would be suitable for powering a future heavy-lift rocket for crew transportation beyond LEO, recalls Bolden. Yet with no near-term plan to develop such a rocket, “NASA was essentially going to be relegated to the sideline.”

In response to the fuming, the Obama administration quickly struck a compromise with Sens. Kay Bailey Hutchison, R-Texas, and Bill Nelson, D-Fla., the leaders of the Senate Commerce Committee that authorizes NASA programs and recommends spending levels: Hutchison and Nelson agreed to support the Commercial Crew program in the pending multiyear spending authorization bill, but the bill also committed NASA to developing a heavy-lift “Space Launch System” for human missions to Mars in the 2030s.

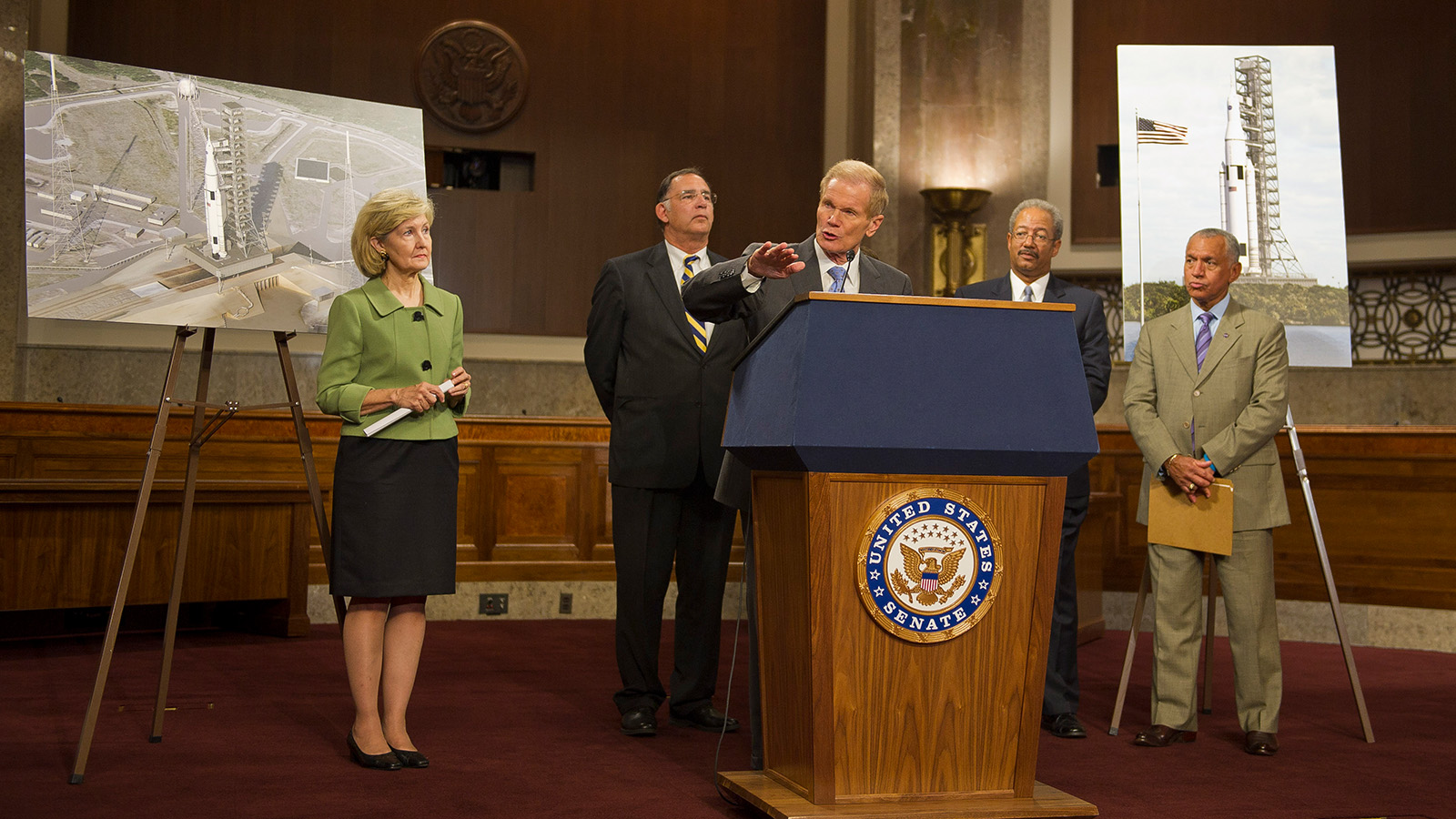

The next year, Hutchison was a featured speaker at the Capitol Hill press conference where NASA unveiled an early design of the first SLS rocket, the one that would be launched by the end of 2021 if all goes as planned. It was the SLS Block 1 design, the version that lacks the more powerful upper stage but could still send the 22.7-metric-ton Orion crew and service modules toward lunar orbit in a single launch ahead of a planned larger version, Block 1B.

The new program represented “a commitment that NASA” — Hutchison paused for emphasis — “NASA is going to lead the pack.” The private rockets and spacecraft that would launch astronauts to ISS were a crucial capability, “but the leader is going to be the launch system that is being announced today.”

It was a clear answer to the question about NASA’s unique role: private companies could take over crew transportation to LEO, freeing up NASA to focus on more ambitious destinations.

The poster board drawings of SLS on each side of the speakers certainly looked the part: Two massive solid rocket boosters flanked a white core stage reminiscent of the Saturn V (though NASA would later leave the core stage bright orange, the natural color of its insulation). The design was produced by an internal NASA working group that over the span of a year solicited feedback from space companies and considered dozens of designs and mission scenarios in which one or multiple rockets would launch astronauts in crew capsules, says AIAA Executive Director Dan Dumbacher, who co-chaired the working group as the then-deputy associate administrator for NASA’s Exploration Systems Development division.

The group’s findings answered the technical question about the necessity of a big rocket, concluding that launching a single Saturn V-class rocket was the most efficient option for delivering astronauts to within range of Mars or other deep space destinations, both in terms of cost and crew safety.

Dumbacher compares the strategy to the one employed by most first-year college students moving onto campus: “You pack up all your stuff and put it in mom’s SUV or on one giant moving van. You don’t spread it out across 20 smaller trucks.”

This endeavor would be like no other in NASA’s history, however. During development of the space shuttle fleet, the Saturn Vs and their predecessors, mission requirements alone had guided NASA designers — how much thrust was required to launch X number of astronauts in a Y-sized capsule to the desired destination. The working group was given a new constraint: Congress in the multiyear authorization act directed NASA to utilize existing contracts from the space shuttle and Constellation programs “to the extent practical.”

At the time, that seemed like a good way to stay within the $3 billion annual spending limit for the program, which equated to an $18 billion total cost for the first SLS rocket, its Orion crew capsule, service module and launch pad upgrades. The estimate for all that would later grow to $38 billion, but NASA says that figure also includes the cost of test articles, facility upgrades and components for future rockets and capsules.

The group’s recommendation, reflected in the SLS drawing unveiled at the 2011 press conference, was largely pieced together from disparate components — a Boeing-built core stage would be a brand new design, but powered by RS-25 engines from the shuttle orbiters; an upper stage derived from the blueprint for a Delta IV upper stage; and the Lockheed Martin-built Orion crew capsules originally designed to fly atop Ares rockets.

In some cases, the constraints limited the technical performance of SLS. For instance, NASA opted to modify and refurbish the 16 remaining RS-25s from the shuttle orbiters, even though their liquid hydrogen fuel is not as energy dense as the hydrocarbon RP-1 kerosene that powered the Saturn V, meaning there’s less energy per unit of fuel. Also, the projected cost and time of developing the new core stages meant NASA had to delay development of the Block 1B variant, in which a more powerful upper stage could propel an additional 11 metric tons to the moon.

Converting existing hardware from the Constellation and shuttle programs afforded a political advantage “in selling the rocket and keeping it sold” to U.S. lawmakers writing NASA’s annual budget, says Barnes, the former Boeing employee, who oversaw SLS design and early construction as program manager between 2013 and 2015. A former NASA official describes the trade-offs more bluntly: “Do you want a rocket program or not?”

What went wrong

By 2015, when Barnes retired, the original 2017 launch date had been bumped following the critical design review that cleared the contractors to begin flight hardware production in earnest. The new target of July 2018 amounted to a seven-month slip — not unheard of in the history of NASA as program schedules are refined, but the SLS launch date kept moving to the right. July 2018 became November 2018, which turned into December 2019, then June 2020. A new November 2020 target changed to mid-2021. Most recently, a November 2021 launch date has given way to NASA’s current estimate of late 2021 or early 2022.

So what happened? There is no single answer.

Some point to a series of technical errors by NASA and its contractors. According to a March 2020 report by the NASA Office of Inspector General, the errors “collectively have resulted in $2 billion of cost overruns and increases and at least 2 years of schedule delays.”

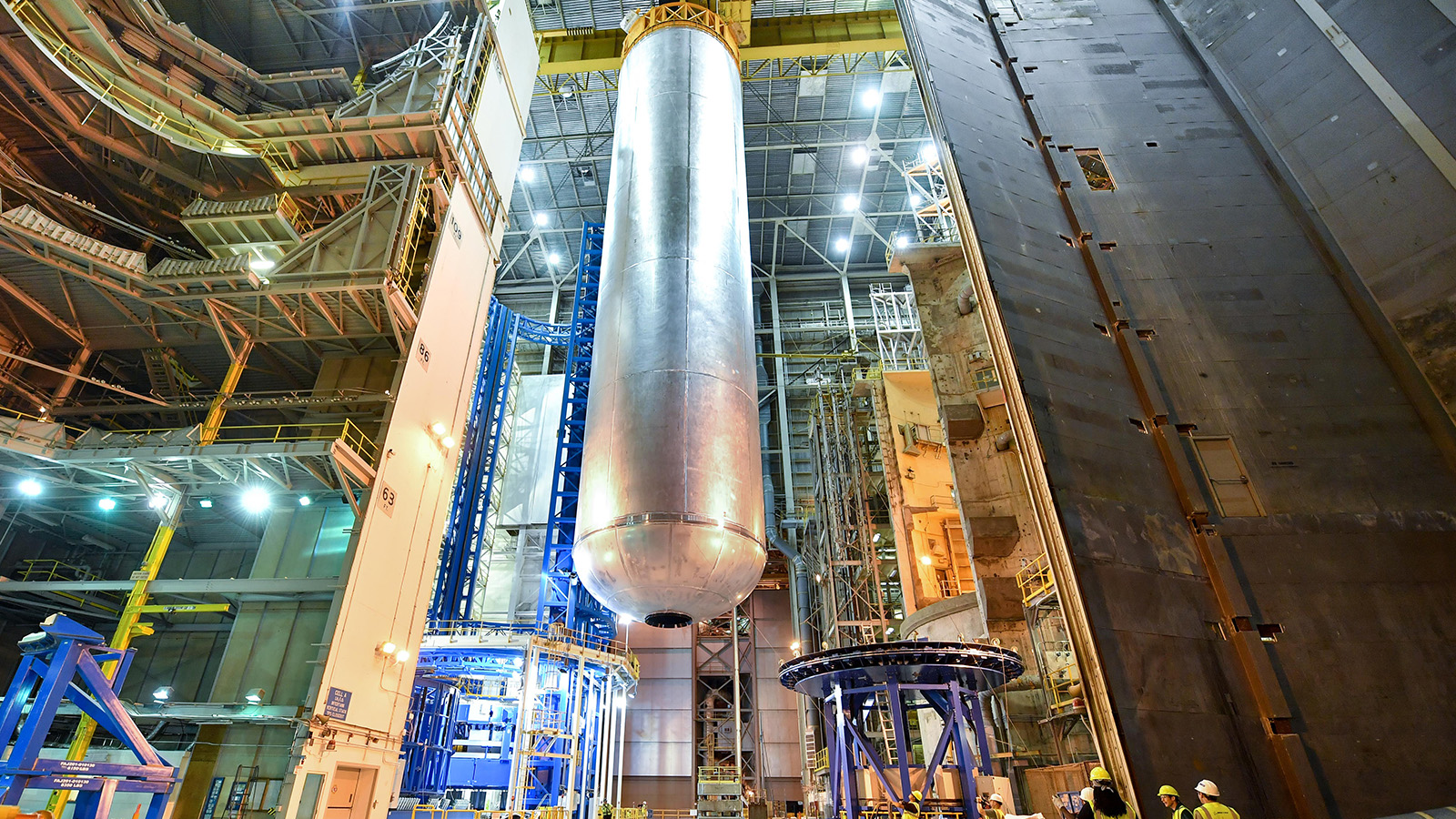

Boeing and NASA say some of these errors can be attributed to the challenges of first-time production, including the installation of custom tooling at NASA’s Michoud Assembly Facility in Louisiana that took longer than expected.

The single biggest tooling error was the misalignment of the giant welder that assembles the aluminum barrels, domes and rings that comprise the core stage propellant tanks. After Boeing’s subcontractor completed the cylindrical, cage-like welder in late 2014, technicians discovered the rails on which tank components are moved up and down via a metal ring were slightly lopsided, so the ring couldn’t lift the core stage pieces to the full height of the 50-meter-tall welder.

NASA later found that the subcontractors didn’t reinforce the floor at Michoud before installing the welder, so test hardware production had to be halted while the foundations were fortified and the tool rebuilt.

“When you start off and you haven’t even finished the facility in which you’re going to do the manufacturing and you find that you’re delayed by two years because the tool’s not right, that’s not good,” former NASA Administrator Bolden says. “You find that you have things that were not forecast or unforeseen and that’s what brought us to where we are” with the program.

Compounding the technical errors is flat program funding, says analyst Dreier.

Consider the budget for the Saturn V rockets, which was $8 million (in 2020 dollars) in fiscal 1961, the first year of development. Congress steadily approved more money for Saturn V year after year through fiscal 1966, when funding peaked at $11.6 billion (in 2020 dollars). In contrast, during the first five years of the SLS program, Congress approved a $300 million increase between fiscal 2011 and fiscal 2016.

“They were told to do an Apollo-level rocket program with a 21st-century budget,” says Dreier, meaning that when delays arose such as the one with the Michoud welder, there were no additional funds to keep the program on schedule.

And the nature of the cost-plus contracts under which SLS work is done means that NASA has paid more than expected for rocket components. For instance, the $2.8 billion contract the agency awarded Boeing in 2011 for the first two core stages and preliminary work on the Block 1B upper stage had to be modified in early 2020. The new value is $9 billion.

Noone of Embedded Ventures pointed to the hierarchy of the SLS program as a reason why NASA and its contractors have struggled to stay within schedule and cost estimates. Unlike private launch companies including SpaceX that manufacture the majority of their rocket components in-house, SLS core stage prime contractor Boeing builds the stages at Michoud, Orion prime contractor Lockheed Martin constructs capsules in Colorado and at NASA’s Kennedy Space Center in Florida, and so on. And each prime has its own network of subcontractors and suppliers, with parts coming from across the U.S. According to a NASA webpage of Artemis program suppliers, SLS in 2019 had suppliers in 41 of the 50 U.S. states, plus the District of Columbia.

“That is a very slow-paced machine,” says Noone, who before co-founding his venture capital firm was a founder and the chief technology officer at California launch startup Relativity Space, whose approach of 3D printing their rockets cuts down on the number of required technicians and components.

In the case of SLS, he says, the multiple layers of subcontractors mean that reacting quickly to unexpected production errors or expediting work “is almost impossible.”

But political support plays a role here as well, Dreier contends. The thousands of jobs across the country created by the program strengthens the rationale for Congress to continuously fund SLS. “It has, in a sense, a luxury of being so strongly supported that, in a way, inefficiency is not a bug but a feature of the system.”

As with any program, there have also been factors out of NASA’s control. Since 2011, a series of tropical storms and hurricanes have intermittently halted SLS core stage production at Michoud. In late August, for instance, Michoud was closed to guard against the strong winds and floods from Category 4 storm Hurricane Ida. Though no SLS hardware was damaged, officials told me the halt amounted to a three-week delay.

Like everyone, NASA has also had to contend with telework and social distancing restrictions prompted by the covid-19 pandemic. In August alone, 100 employees tested positive at Kennedy where technicians are assembling the first SLS, Nelson — now NASA’s administrator — said during an early September media roundtable. He didn’t say how many of those cases were people working on SLS.

A tale of two rockets

Despite the delays, the first SLS rocket continues to take shape in the Vehicle Assembly Building at Kennedy. The next major step was scheduled for early October, when technicians from NASA and its contractor Jacobs were to roll the Orion capsule over to the VAB and begin joining the two vehicles for final tests.

Several states over, in Texas, another monster rocket is coming to life. Standing at 120 meters tall, the first prototype of SpaceX’s shiny stainless-steel Starship is even taller than the 98-meter-tall SLS Block 1 when both rockets are fully stacked.

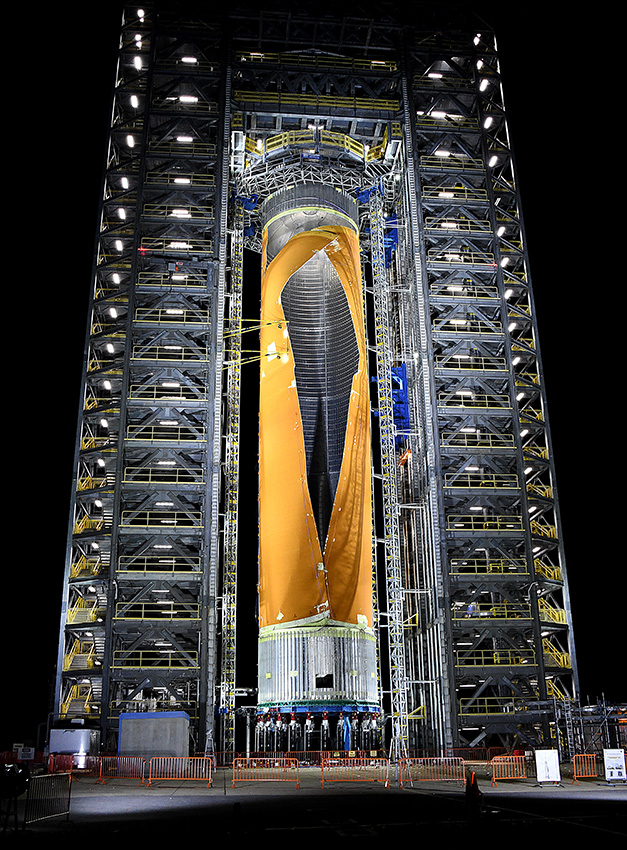

And the differences don’t end there. The SLS program has spent a decade and $19.6 billion. Along with constructing the hardware for the upcoming first SLS launch and some components for future rockets, the time and funds have been spent finalizing the Block 1 design and building and ground testing a handful of test articles including propellant tanks, as well as setting up the flow of operations for long-term production.

By contrast, over the span of nine years SpaceX designed an entirely new liquid-methane engine to power Starship and built at least the first 100 of these Raptor engines, constructed its Starbase facility in Texas and launched upper stage prototypes to low altitudes about 10 times. Most of the flights ended in spectacular explosions, but SpaceX says the rapid build-fly-repeat cycle has prepared the company to conduct the first orbital test flight of a Starship upper stage atop a Super Heavy booster before the end of this year, which means Starship could possibly beat SLS to space. However, that’s pending completion of an FAA environmental assessment.

Not that NASA has anything against Starship. A Starship upper stage could ferry two astronauts from lunar orbit to the surface of the moon for a base-first landing in 2024, under a $2.9 million contract awarded by NASA in April. All but an initial $300 million remains in limbo because of ongoing protests and lawsuits from Blue Origin of Washington state, which also bid for the contract. NASA in August agreed to suspend Starship work until Nov. 1 while a lawsuit before the U.S. Court of Federal Claims is litigated, but none of this stops SpaceX from funding Starship development and testing on its own dime or pulling from the roughly $140 million NASA previously awarded the company under 2019 and 2020 study contracts.

Noone says the rapid progress of Starship is an indicator that the private launch market has matured to the point where NASA should transition from an operator to a customer, as it’s done with the transport of astronauts to ISS.

“Objectively, SLS will be obsolete probably before it takes off from the pad,” he says, so NASA should instead focus on what he calls “beyond launch” markets to advance technology that’s too risky for private companies.

Others aren’t so sure. Although a Starship could send more payload to orbits beyond LEO — 100 metric tons to the 27-metric ton capability of an SLS Block 1 — the design requires a more complicated method to transport that payload to the moon and deep space.

In the case of SLS, a cryogenic upper stage propelled by a single Aerojet Rocketdyne RL-10 engine provides the thrust for a translunar injection maneuver to send Orion on a trajectory to lunar orbit. In the Starship design, the rocket’s upper stage would dock in LEO with a propellant depot and be refueled through a method SpaceX has not specified, then fire its six liquid methane Raptor engines for the trip to lunar orbit.

In a series of tweets in August, Musk said about eight “tanker flights” with additional Starships would be required to fill up the propellant depot, and these would be spaced out about six months before launching the lander.

SLS contractors in August touted the relative simplicity and proven design of their rocket during a media roundtable at the Space Symposium in Colorado Springs, Colorado. The SLS design is better suited for deep space missions, Boeing’s director of sales and marketing for deep space programs David Burks told me, because it can traverse “all the way to your destination in one launch.”

He also contends that the Starship design won’t be a one-size-fits-all vehicle. Consider robotic probes to the outer solar system: “It just makes no sense” to launch aboard a Starship with a 100-metric-ton capacity “if I’m taking 6 tons to Jupiter. I don’t need that extra weight.”

Even if Starship succeeds, one former NASA chief sees a compelling reason beyond technical performance for a government rocket program.

“We have private package and delivery services, but we still have a U.S. Postal Service for good reason,” says Mike Griffin, NASA administrator between 2005 and 2009. “I would prefer that there exists in perpetuity an independent U.S. national capability to access and utilize space, irrespective of what commercial entities decide to do in addition. Not instead of, in addition.”

Analyst Dreier agrees, but for a slightly different reason. Yes, relying on any single private company that could in theory go out of business would put the U.S. in a “precarious position,” he says. More importantly, SpaceX’s construction of an SLS-class rocket doesn’t mean other companies will follow suit.

“Maybe we’ll have this discussion again in 10 years, and at that point there will be a mature heavy-lift market with a range of vehicles that have proven reliability and financial stability, to the point where the government can bow out of this aspect of the marketplace.”

Even if the first SLS launch ends in a fireball, it’s unlikely the program would be canceled, contends Laura Forczyk of the Georgia consulting firm Astralytical. That would require a massive shift in NASA’s human spaceflight program and the rocket’s unwavering support from U.S. lawmakers.

“Nothing’s going to happen this year or next year that will change anything,” she predicts, given the massive amounts of hardware in various stages of production.

Case in point: NASA isn’t going to wait and see if the first launch succeeds and is in the midst of finalizing the terms of a new contract with Boeing. The deliverables? Ten SLS core stages and eight of the powerful upper stages that would fly on the Block 1B variant.

About cat hofacker

Cat helps guide our coverage and keeps production of the print magazine on schedule. She became associate editor in 2021 after two years as our staff reporter. Cat joined us in 2019 after covering the 2018 congressional midterm elections as an intern for USA Today.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.