Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

Elaine Motyka of Technetics Group shares an insider's account

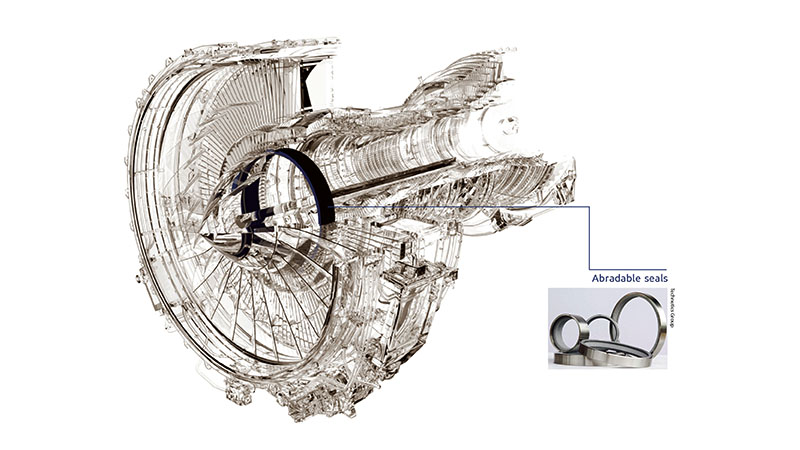

In the compressor section of a jet engine, abradable seals fill the gap between the turbine blade tips and the engine casing. During thousands of cycles between flight idle and high power, these seals perform the critical function of mitigating the leakage of air and gases that would rob the engine of propulsion and payload efficiency. A seal must be replaced once it decomposes too much due to erosion, impact damage, or high temperature oxidation.

In 2013, Technetics Group set out to make a new seal material and ultimately a new seal that would last longer and impart less wear on turbine blades compared to seals made of conventional materials, including today’s widely used fiber-metals.

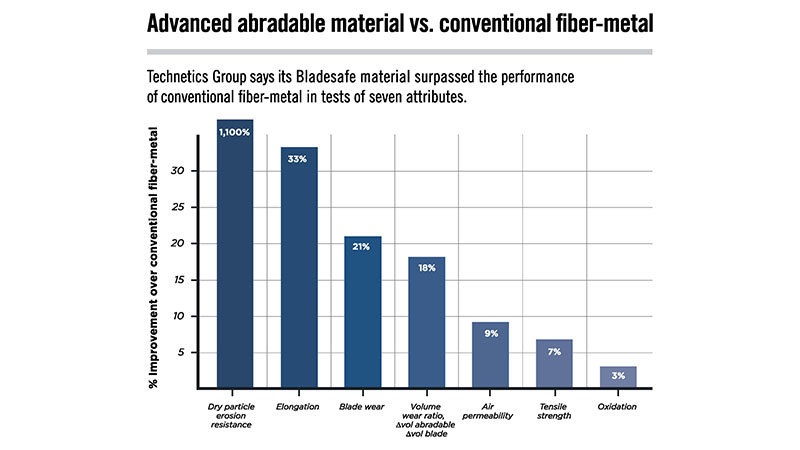

In 2016 we completed rub tests on a new metal matrix composite, or MMC, seal material. This advanced abradable material, which we’ve trademarked as Bladesafe, is a proprietary blend of metal alloys and solid lubricating ceramic and we are ready to manufacture seals from it. Our tests were encouraging and we are confident that turbine manufacturers will soon want to conduct engine testing with seals made of this new advanced abradable material.

Getting to this point required addressing some fascinating materials engineering challenges. Today, with blade-tip surface speeds sometimes exceeding 300 meters per second, rub events between a seal and the surface tips are more likely to damage the blades, even though the seals are abradable to absorb the energy of the impacts. Hard coatings applied to the blade tips are often a method used to protect them from wear. This is not an optimal solution, as the coatings add cost, weight and have the potential to delaminate.

An optimum seal would allow rub events without significant damage to the blade and without requiring a tip coating. The seal would resist erosion, oxidation and air leakage while maintaining enough thickness to reduce the blade-casing gap.

Tradeoffs

Seals have typically been attached to the inner surface of the engine casing or a backing plate in one of several methods, depending on the kind of engine. Layers of metal alloy or honeycomb materials can be heat brazed onto the surface. Fiber-metal seals, where alloy fibers are strengthened by diffusion bonding or sintering, can also be attached by vacuum brazing. Composite coatings can be deposited by thermal spray methods onto the interior of the casing.

Each of these current materials and methods comes with tradeoffs that Bladesafe avoids. Fiber-metal causes less damage to turbine blades than honeycomb, but it is more permeable to air and gases and it has very low erosion resistance. Thermal spray coatings are more gas-tight and erosion resistant than fiber-metals, but they are so damaging to the titanium blades that hard coatings must be applied to them for wear protection. In addition, thermal spray coatings are limited in applied thickness, whereas honeycomb and fiber-metal can be applied up to several millimeters, allowing for tighter clearances.

We began our MMC project with a special understanding of aircraft turbine seals, fiber metals and sintering. Technetics has been manufacturing fiber-metal abradable seal material for over 40 years with more than 1 billion flying hours on numerous engines. This material is fabricated from fine metal fibers that have an effective diameter of 10-20 microns and a length-to-diameter ratio of 60-90:1. The fibers are typically derived from various metals depending on the specific needs of the turbine engine application. The fiber is “felted” into sheet form and subjected to a proprietary sintering cycle in which bonds form at points of contact between the fibers. The sintered sheet is then rolled to the required thickness and density and cut to size. The final product is a strip of fiber-metal material that is ready to be brazed or mechanically attached into the case or onto a backing plate.

Fiber-metal material is porous by nature with an apparent density, typically applied at 15 to 30 percent of the wrought material. We can design the material to have an ultimate tensile strength of 500 to 3,000 psi, depending on the seal requirement. UTS can be set independently of other physical properties via the manufacturing process. This flexibility is important because UTS largely determines the abradability and erosion properties of the material. This ability to “tune” the abradability and erosion properties gives the designer flexibility to select the optimum material for each application. The new MMC material maintains this designer flexibility.

In rub events where the blade tip speed is relatively low (less than 300 meters per second), conventional fiber-metal, including ours, does not cause significant wear to titanium blades but it has relatively low erosion resistance to particles in the gas path. In a rub event where the tip speed is high (300 m/s or greater), highly porous fiber-metals eventually compact and overheat from friction forces, damaging the blades and causing localized melting or even failure of the seal.

Our MMC seal material addresses most of these tradeoffs and shortcomings. The composition and structure of the MMC mitigate compaction and friction while they also strengthen the material against erosive particles. The MMC has increased apparent density 30 to 60 percent, which improves permeability. Like conventional fiber-metal seals, the MMC can still be attached to the interior of the casing using vacuum brazing methods. We have engineered the MMC with unique structure and properties to cause reduced wear of the blade as well as to increase the erosion resistance of the seal itself at higher speeds and temperatures. The unique material of the new seal provides a sacrificial abradable response that is better than conventional fiber-metal to a blade incursion while maintaining resistance to erosive particles similar to thermal spray coatings.

Tests

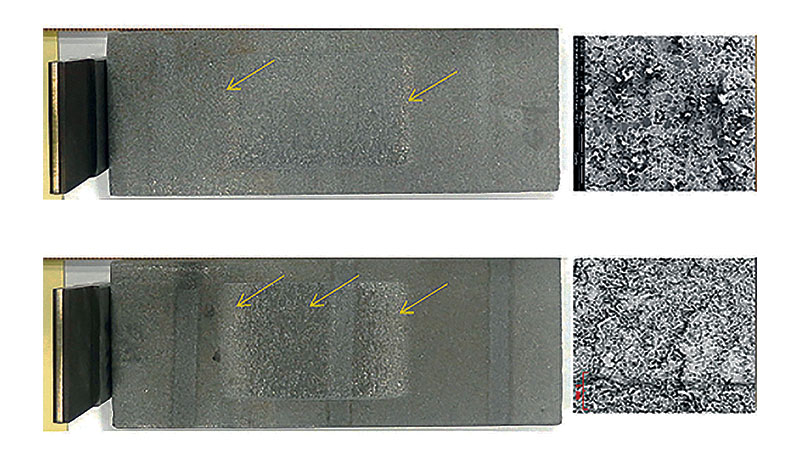

We know these facts from the series of rub tests we conducted. Using a high-speed abradable test rig at another organization, our engineers conducted iterative testing of several developmental concept materials. The rig was comprised of test blades mounted on a rotating disc that can create blade speeds up to 500 m/s. The MMC abradable material was brazed to a shroud or backing plate to simulate the casing. This sample was moved into the rotating blade at controlled incursion rates. Wear of the blade and the seal material was documented. Initial testing focused on the same titanium alloy found in most turbine blades, Ti6A14V. We ran the same tests on a sample of our conventional low-density fiber-metal material. Compared to fiber-metal, the advanced abradable material has higher apparent density, increased tensile and yield strengths, reduced percent-elongation (or ductility), increased dry particle erosion resistance, reduced air permeability and improved oxidation resistance at higher temperatures.

Under the high-speed, moderate-incursion blade rub conditions, the advanced abradable material resists compaction and densification, interrupting the damaging sequence of events typical of conventional porous fiber-metal abradable materials. In addition to resisting compaction and densification of the surface, the advanced abradable material has been engineered with reduced ductility to allow for localized micro-fracture under blade contact, resulting in a better sacrificial wear response compared to fiber-metal. The advanced abradable material also incorporates advanced high-temperature solid lubricant ceramic material so that the seal acts as its own lubricant to reduce the friction coefficient where blade contact does occur. The degree of surface densification, increased contact area, and heat generation normally observed with fiber-metal is significantly reduced in the advanced abradable material.

Under rub conditions with uncoated Ti blades at high surface speed (410 m/s) and moderate incursion rate (50 microns/s), the combination of high strength and reduced ductility allows the advanced abradable material to wear by mechanisms, such as cutting, that are known to be less damaging to blades. We know from experience that cutting as a wear mechanism requires less energy for material removal compared to adhesive wear and rupture mechanisms. When adhesive wear mechanisms dominate, Ti from the blade adheres to the seal material and the alloy from the seal material adheres to the blade, creating rough surfaces with high friction forces and significant localized heating. The heating weakens both the seal and the blade tip, accelerating wear of both the blade and the seal and creating the risk of cracking of both.

The benefit of a wear mechanism where cutting dominates and compaction of the surface is reduced is that less heat is generated at the rub surface. Consequently, the denser and stronger advanced abradable material can have a rub event with the Ti blade without increasing the severity of the blade wear.

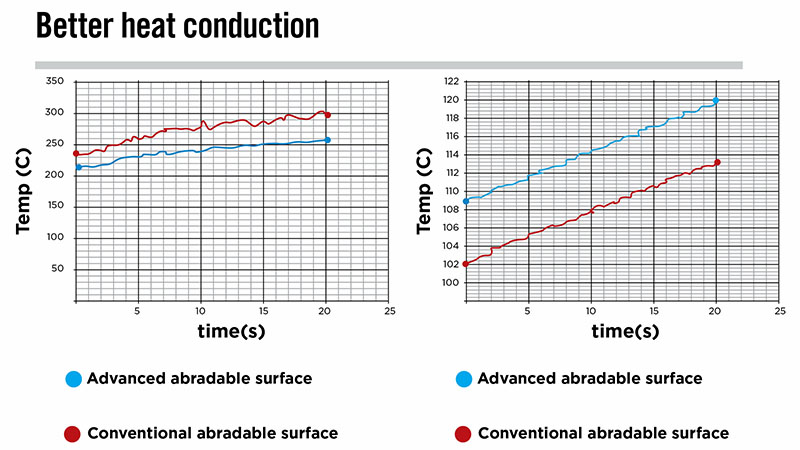

In addition to wear of the blade and the abradable material, temperatures were measured of the abradable surface and of the backside of the shroud to which it was brazed. The temperatures are consistent with the abradability observations; that is, the denser MMC had lower surface temperature due to more favorable cutting wear mechanisms. The backside of the shroud (or casing) had higher temperature as the denser material had better heat conduction.

Compared to thermal spray coatings, the advanced abradable seal material has a thickness advantage. It can be made in sheets as thick as 10 mm, whereas thermal spray is typically applied to the interior of a casing 2-3 mm thick. Because of the greater thickness, the turbine engine designer can accept deeper blade incursions, such as those from greater surge or out-of-round conditions, and have a minimal initial gap between blade tip and casing for maximum compressor efficiency.

All told, we found that under high-speed uncoated Ti6Al4V blade incursion, compared to conventional fiber-metal, less heat is generated at the abradable surface, less blade wear occurs, less abradable seal wear occurs, and wear mechanisms involving blade-damaging adhesive transfer are reduced. The Bladesafe advanced abradable material also has a higher dry particle erosion resistance and lower air permeability. It is denser and stronger than fiber-metal and has a lower oxidation rate at 650 degrees Celsius [1,200 Fahrenheit], the gas path temperature inside typical aircraft engine compressors.

Elaine Motyka is the principal materials engineer at Technetics Group in Deland, Florida. She is the technical leader of the team that developed a new metal matrix composite seal material that is now ready to be marketed to customers. She holds a Bachelor of Science degree in mechanical engineering from Worcester Polytechnic Institute in Massachusetts and a Master of Science degree in materials engineering from Rensselaer Polytechnic Institute in Troy, New York.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.