Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

The Inlets, Nozzles and Propulsion Systems Integration Technical Committee focuses on the application of mechanical design, fluid mechanics and thermodynamics to the science and technology of air vehicle propulsion and power systems integration.

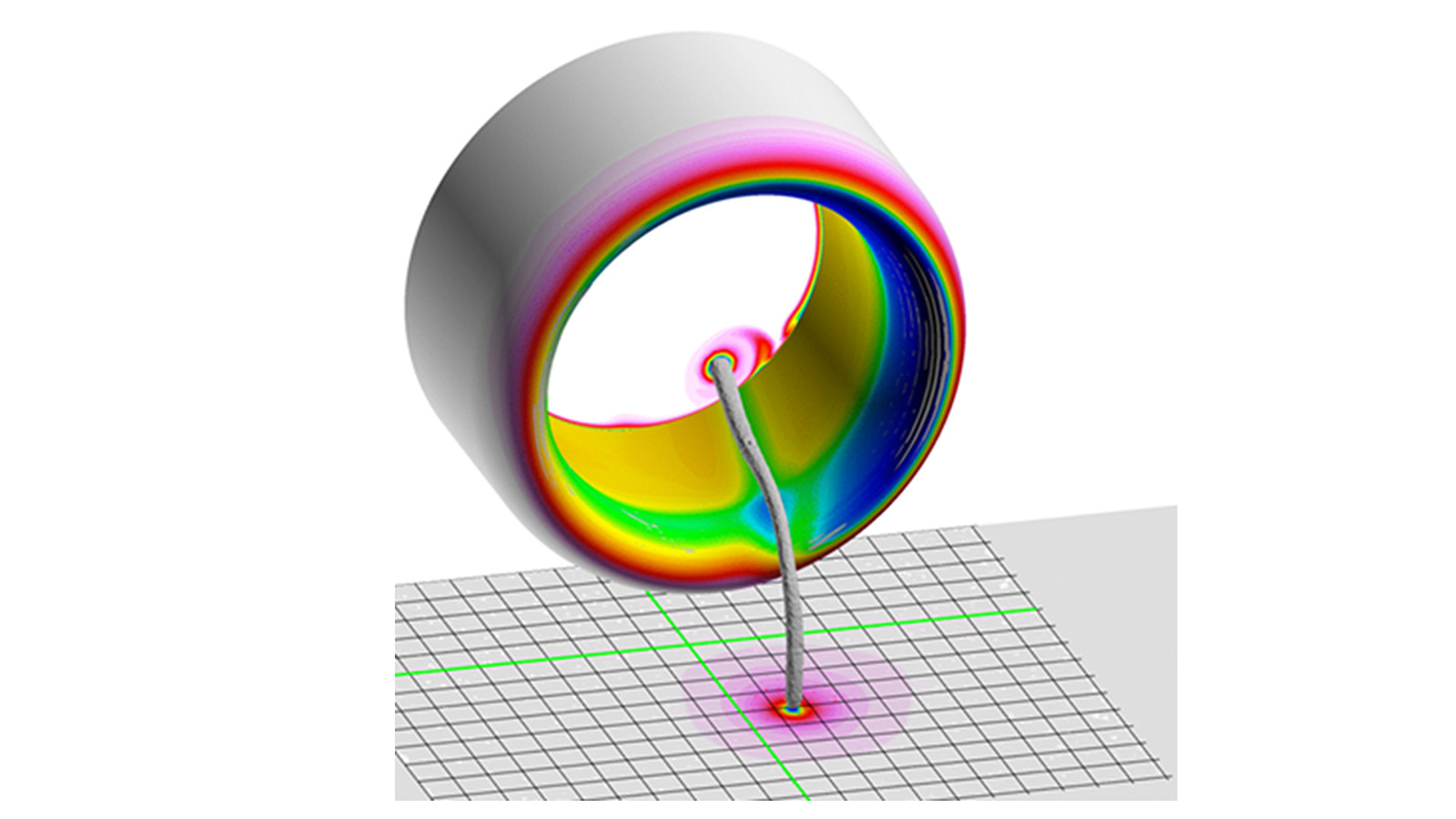

In January, researchers at the fifth AIAA Propulsion Aerodynamics Workshop demonstrated novel computational fluid dynamics methods on two test cases that were chosen to identify shortcomings in CFD modeling practice and thereby direct future research. The test cases provided rich datasets that enabled new multiphysics approaches to be validated. The results were vastly superior to the use of simpler models. Participants studied grid generation, turbulence and physical modeling, and boundary condition modeling and identified preferred practices. For one test case, participants predicted deck surface temperatures and boundary-layer profiles for a film-cooled non-adiabatic nozzle with an aft deck. Results showed that conjugate heat transfer modeling is critical to predicting temperature profiles and that scale-resolving simulations enable better agreement with experimental measurements than steady-state calculations for temperatures in the wall boundary layers. For the second test case, researchers assessed the ability of their CFD methods to predict ground vortex formation at the engine inlet under different crossflow conditions. This test case showed that CFD can contribute to the understanding of this problem. Guidelines for grid generation were among the outcomes of this important set of simulations.

Early this year, researchers at NASA’s Glenn Research Center in Ohio analyzed experimental data to improve the knowledge of flow physics associated with a boundary-layer ingesting, distributed propulsion system. The experiment, conducted in 2019-2020 in a subsonic wind tunnel with a 20-by-30-inch (50-by-76-centimeter) test section, specifically examined the influence of incoming boundary-layer thickness on the performance of the system. Researchers mounted the propulsion model, integrated with electrical fans, on a flat plate and tested it at subsonic speeds. Hot-wire anemometry and static pressure measurements enabled detailed characterization of the incoming boundary layer and the downstream flow field. Trip rods placed near the leading edge of the flat plate modified the boundary layer. The researchers assessed the overall system performance by estimating thrust, flow power and input power to the fans. Results indicated that ingestion of a thicker boundary layer yielded a net improvement in the performance of the system.

In May, the EcoPulse distributed propulsion hybrid aircraft demonstrator, developed by Europe-based Airbus, Daher and Safran completed wind tunnel testing at the Airbus facility in Filton, England. The tests evaluated the performance characteristics of the propeller and electrical engine cooling concepts. Propeller performance testing included thrust and force measurements for different engine power levels and rotations-per-minute settings, as well as propeller wake flow visualization behind the engine, which helped characterize the interaction between the propeller and the wing. Researchers recorded dedicated engine and air temperature measurements to assess the effectiveness of the cooling technologies. The wind tunnel tests will enable estimation of the propulsion system’s power and the aircraft demonstrator’s overall energy performance.

In July, Pratt & Whitney Canada said it would continue work on its hybrid-electric propulsion technology and flight demonstrator program as part of a $131 million ($163 million Canadian) investment, with funding from the governments of Canada and Quebec. The new hybrid-electric propulsion technology, to be integrated into a De Havilland Canada Dash 8-100 flight demonstrator, will deliver a 30% reduction in fuel burn and carbon dioxide emissions, compared to a modern regional turboprop airliner. The demonstrator features technologies already developed by P&WC and Collins Aerospace, including an advanced electric motor and controller. This program is a successor of the Project 804 joint development program between P&WC and Collins Aerospace.

Contributors: Dyna Benchergui, Nicholas J. Georgiadis, Puja Upadhyay, Chad M. Winkler and Khairul B. Zaman

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.