Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

The Materials Technical Committee promotes interest, understanding and use of advanced materials in aerospace products where aerospace systems have a critical dependency on material weight, multifunctionality and life-cycle performance.

The aerospace materials community this year sharpened the leading edge of its research for operations in extreme environments. Space flight and habitation led the year, with improved cryogenic actuation efficiencies, higher resolution hypersonic and hypervelocity testing, and advances in high-temperature, space flight and habitation.

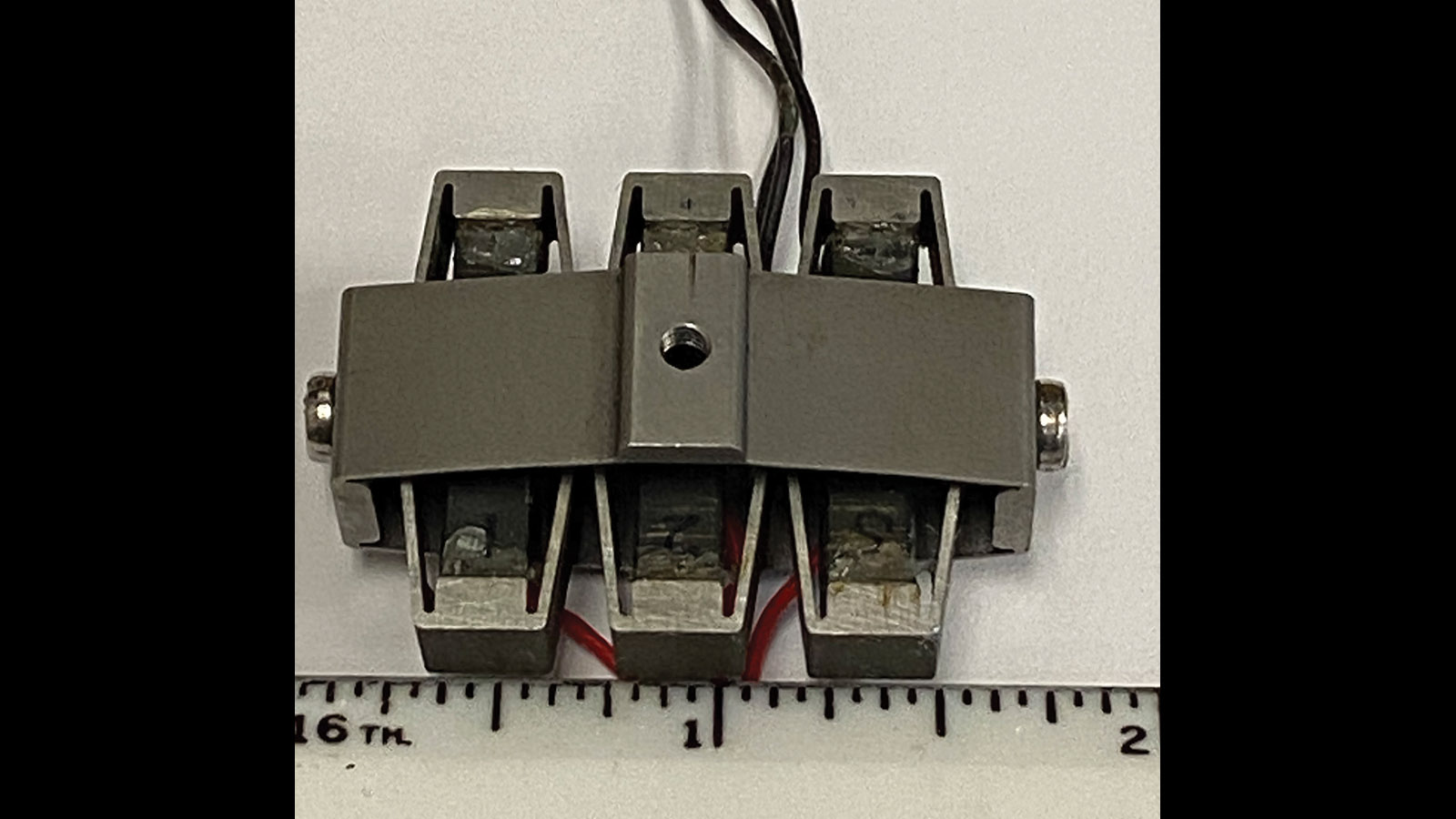

In February, Tian-Bing Xu, a professor at Old Dominion University in Virginia, led a group that collaborated with PolyK Technologies in Pennsylvania to demonstrate a Relaxor piezoelectric Pb(Mg1/3Nb2/3)1-xTixO3 (PMN-PT) single crystal actuator. It showed excellent cryogenic actuation properties with 80% ultra-high energy efficiency. This design may be a game changer for cryogenic fuel management for advanced rocket propulsion systems, space instrumentation and optical system controls and lead to advanced space actuators for NASA missions. The output sustained sufficient stroke and force to drive cryogenic components for broad aerospace applications. In addition, PMN-PT materials may be used to make ultra-high-efficiency cryogenic ultrasonic motors for space drillers and robotics applications.

In April, J.H. Koo, H. Wu and their colleagues at KAI LLC in Texas developed a cost-effective material screening approach for thermal protection systems. The traditional methods of manufacturing TPS for spacecraft are labor-intensive. It is difficult for a designer to visualize TPS materials being fabricated and integrated onto a structure with automation. KAI and the Koo Research Group at the University of Texas at Austin have been developing novel high-performance polymer matrix composites for extreme environments. One of the challenges is to obtain reliable material response data under such conditions. KAI has proposed a comprehensive material screening protocol with fast turnaround time. The developed methods include material formulation study using design of experiments, characterization of materials’ thermal stability, char yield and flammability, and aerothermal ablation testing using an oxy-acetylene test bed to simulate heat fluxes from 100 to 1,600 watts per square centimeter for exposure times with advanced diagnostics. This methodology allows for rapid comparison of material systems and will fast track the development of new TPS materials for space missions. It is being applied to projects funded by the U.S. Defense Department and NASA.

At Embry-Riddle Aeronautical University in Florida, researchers Muhammad Anees, Audrey Gbaguidi and Yachna Gola and professors Daewon Kim and Sirish Namilae collaborated with LUNA Inc. of Virginia on development of piezoresistive sensors to enable full coverage structural health monitoring and impact detection for NASA’s inflatable space habitats. Two flexible sensor prototypes were developed. One consisted of carbon nanotube buckypaper infiltrated with a mixture of epoxy and graphene. The other was an inkjet-printed device based on conductive CNT ink formulated in-house. In January and March, Gbaguidi led the development, characterization and testing of the inkjet-printed sensors as highly conductive and strain sensitive materials. The sensors were embedded into inflatable structure test articles and tested under hypervelocity impact at 7 km/s to simulate micrometeoroid and orbital debris impact. Both sensors detected the location, depth and severity of the damage. The team developed a computational model (percolation-based) with Monte Carlo simulations to simulate nanocomposites with CNT and graphene. The model was first validated against experimental results and was used to find the optimum microstructures for the two sensors fabricated above. The computational model was finalized in May and can model the electrical conductivity and strain and damage sensitivity of nanocomposites in 2D and 3D.

In July, a new class of hybrid nanostructured material development for acoustic and thermal isolation was completed. Researchers from Embraer of Brazil and UFMG/SENAI, a materials company in Brazil, demonstrated that the aero-nanomembranes are 30% lighter than traditional isolation systems and can be tailored for different frequencies.

Contributors: Antonio F. Avila, Audrey Gbaguidi, Hao Wu and Tian-Bing Xu

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.