Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

The Hybrid Rockets Technical Committee studies techniques applied to the design and testing of rocket motors using hybrid rocket systems.

Hybrid rocket technology advanced on several fronts in 2017, from winning a first-ever sounding-rocket competition to developing new combustion techniques and additively manufacturing propellants.

Development of a space-storable hybrid motor for a Mars Ascent Vehicle, part of the proposed Mars Sample Return mission, also made progress. Studies led by the NASA-funded Jet Propulsion Laboratory determined that a storable, single-stage-to-orbit, hybrid propulsion system may be the lowest mass option for an ascent vehicle. Efforts are underway in hybrid grain production, full-scale testing and hypergolic additive investigations to support the launch of an Earth-based demonstrator in 2019-2020.

This past year, NASA’s Marshall Space Center established the capability to produce a monolithic wax-based fuel grain engineered by the Space Propulsion Group. JPL also supported hot-fire testing of this fuel with mixed oxides of nitrogen (nitrogen tetroxide and nitric acid) at both SPG and California-based Whittinghill Aerospace. Additionally, researchers at Purdue and Pennsylvania State universities investigated new solid fuel additives for hypergolic ignition to facilitate in-flight stop/restart capability.

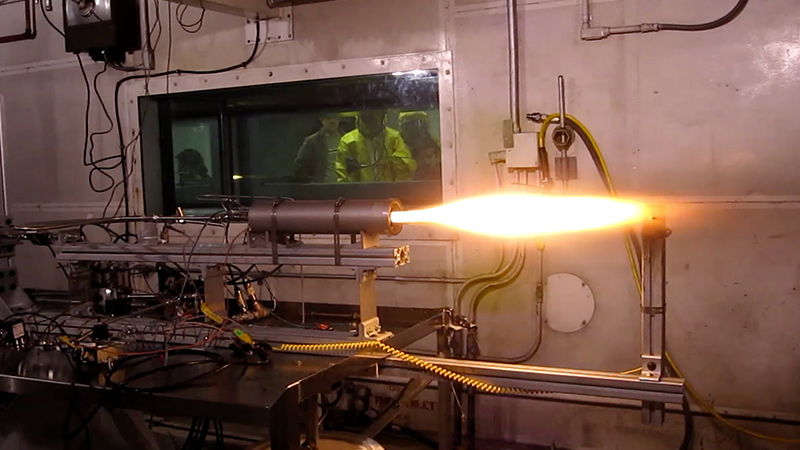

Streamline Automation, KEI, Auburn University and the University of Alabama at Huntsville continued developing a vortex hybrid rocket engine. The engine uses cyclonic flow combustion: an outer, annular flowfield spirals up the fuel port walls while an inner, core vortex carries the combustion products through a unique exit nozzle. Oxidizer is injected at the nozzle end, tangentially into the chamber. The centrifugal forces generated by the swirling flow lead to high, axially uniform regression rates and neutral burning, with controllable oxidizer/fuel mixture ratios that can be further optimized through head-end injection.

Vortex combustion also increases the total impulse and fuel loading efficiency by using a circular-port grain and eliminating sliver formation. The reduction of thermal loading on the chamber walls allows use of thinner and lighter materials. The single-port grain and single-cartridge housing maximizes volumetric loading efficiency while facilitating cleanup between successive uses. Modeling and simulation by Auburn University to optimize the nozzle and engine port geometry have produced a high-performance engine that is capable of very high regression rates. Numerous tests of a 4-inch, 1,000 pound-force vortex engine were carried out at the University of Alabama at Huntsville demonstrating the feasibility of this concept.

In other developments, scientists at the University of Electro-Communications in Tokyo in March developed a design optimization procedure that can extend the range of hybrid rockets. This is based on an extinction-reignition protocol that takes into account flight path stability, duration and range in the thermosphere (80-120 kilometer altitude).

In July, DARPA awarded Florida-based Rocket Crafters a contract to develop a 5,000 pound-force hybrid rocket using its Direct-Digital Advanced Rocket Technology. This uses additive manufacturing to directly print fuel grains and combustion chambers simultaneously using high-energy polymers.

Utah State University tested a novel hybrid thruster that employs medium-grade hydrogen peroxide (80-85 percent) and additively manufactured acrylonitrile-butadiene-styrene as the primary propellants. This operates with a low-grade agricultural oxidizer by preceding the peroxide flow into the thrust chamber with a short burst of gaseous oxygen. An arc-ignition system then ignites the ABS propellant in the oxygen flow, with the peroxide flow starting immediately upon ignition. Thrust levels between 180 and 205 newtons were achieved from multiple on-demand restarts, and specific impulse levels exceeding 215 seconds were reported.

In June, the first Spaceport America Cup was at New Mexico’s Spaceport in partnership with the Experimental Sounding Rocket Association. Out of 110 teams competing to launch a 4-kilogram payload to either 10,000 or 30,000 feet, depending on their choice of propulsion, a student team from the University of Michigan, Ann Arbor, won with a hybrid engine that enabled them to exceed the 30,000 foot goal.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.