Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

The Propellants and Combustion Technical Committee works to advance the knowledge and effective use of propellants and combustion systems for military, civil and commercial aerospace systems.

Hydrogen as fuel has received significant attention from the aviation community in recent years. The combustion of hydrogen is relatively simple and clean, producing water as its only primary exhaust product. There are practical concerns, however, highlighted by the scrubbed launches of NASA’s Artemis I moon mission in August and September. To store in an energy-dense liquid state, hydrogen requires cryogenic (minus 253 degrees Celsius) storage temperatures. Maintaining cryogenic temperatures during transportation and storage presents immense challenges. An alternative clean fuel is ammonia, which is more energy-dense than hydrogen. Ammonia storage and transportation infrastructures are largely in place.

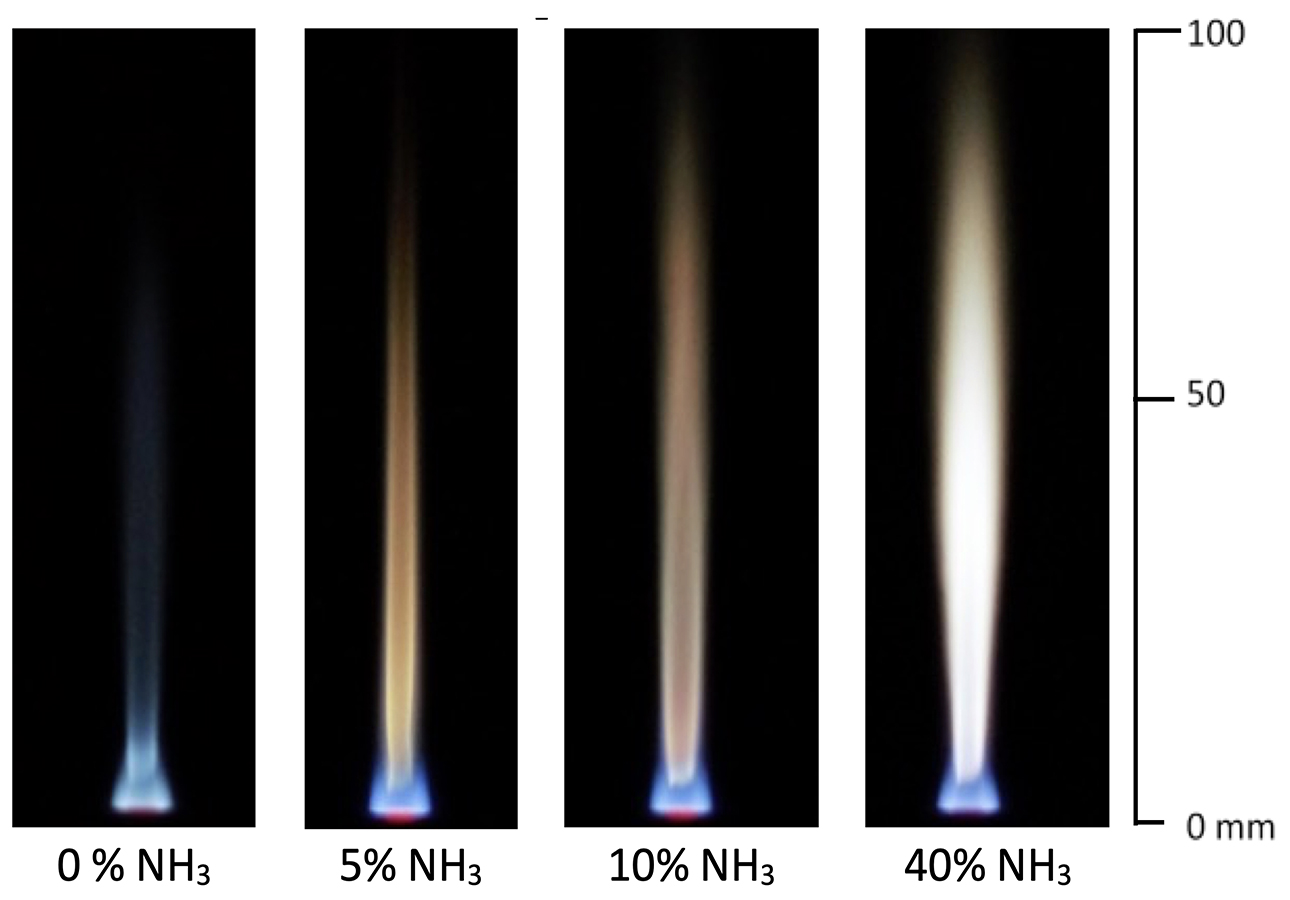

Early this year, the Clean Combustion Group at the University of Sydney in Australia investigated the turbulent combustion of ammonia co-fired separately with hydrogen and hydrocarbons. Co-firing ammonia with a more energetic fuel is important for its adoption in practical systems. The Sydney-piloted inhomogeneous burner was used in these studies to stabilize mixed-mode flames relevant to internal combustion engines. Experiments have shown that adding ammonia to compressed natural gas shifts the flame stability to a different level and location due to the interplay between the ammonia chemistry with the local turbulence.

However, co-firing ammonia with hydrogen in the air can form unacceptably high levels of pollutants, in particular, oxides of nitrogen. First presented at the 39th International Symposium on Combustion in July, researchers at Tohoku University in Japan experimentally investigated product gas characteristics of premixed laminar ammonia-hydrogen-air flames stabilized in a stagnation flow. Their results showed that the maximum mole fraction of nitric oxide produced was greater than that of pure ammonia-air flames, and that nitrous oxide was formed at a fuel-air equivalence ratio of approximately 0.6. The researchers also numerically investigated reaction pathways involving production of nitrous oxide and possible reduction mechanisms.

Researchers at Sandia National Laboratories’ Combustion Research Facility in California performed petascale direct numerical simulations on turbulent premixed ammonia-hydrogen-nitrogen-air flames in January to gain insight about the formation of undesirable emissions. The temporal evolutions of the global net production rates of nitric and nitrous oxides were measured as mass produced per unit heat release. The most significant direct numerical simulation finding, also first presented at the International Symposium on Combustion, with respect to the deployment of ammonia-hydrogen-nitrogen-air combustion in industrial applications was the significant reduction (about one-eighth) of nitric oxide production at 10 bar compared to 1 bar. Unfortunately, at high pressure, there remains a concurrent greater production of nitrous oxide.

Researchers at the University of California Riverside also explored utilization of ammonia in the solid phase as ammonia borane. The thermolysis of ammonia borane forms BNHx clusters with poor oxidation kinetics. The researchers investigated these fundamental reactions and have shown the use of ammonium-based oxidizers, such as ammonium perchlorate, enable ammonia borane to follow an alternative reaction pathway inhibiting BNHx formation. Earlier this year, they showed that when ammonia borane is present in polymer matrices of carbonyl compounds, it will disintegrate into reactive ammonia and diborane gases. This chemical pathway enables the solid-state storage of gaseous reactive fuels, ammonia and diborane, and their co ntrolled on-demand release for high-energy propulsion applications.

In August, the London Tech Bridge, a collaboration between the U.S. Navy and Royal Navy, hosted a United Kingdom industry engagement on the potential of ammonia as an energy source. The participants included U.K.-based Dolphin-N2, U.K.-based AFC Energy, China-based Sunborne Systems and U.K.-based TED Gen and BMT. Discussions focused on ammonia fuels, both as a hydrogen carrier and a fuel itself, and the logistics and ship-design considerations of integrating ammonia into naval systems.

Contributors: Jeffrey Brewer, Jacqueline Chen, Andrea Gruber, Akihiro Hayakawa, Hideaki Kobayashi, Assaad Masri, Martin Rieth and Michael Zachariah

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.