By Brad Rafferty

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

The Ground Testing Technical Committee focuses on the test evaluation of vehicles, structures, and aerospace systems, subsystems, and components in ground- based facilities such as wind tunnels, environmental facilities, and engine test facilities.

In March, Boeing company Aurora Flight Sciences completed testing for its high-speed vertical takeoff and landing concept at Boeing’s V/STOL wind tunnel in Pennsylvania, as part of its work on DARPA’s SPRINT (Speed and Runway Independent Technologies) program. In July, DARPA selected Bell Textron for Phase 2 of the program to complete design, construction, ground testing and certification of the X-plane demonstrator.

In March, Eve Air Mobility announced it completed a powered test of a scaled model of its electric vertical takeoff and landing aircraft at the German-Dutch Wind Tunnels Large Low-Speed Facility in the Netherlands. The team assessed aerodynamics, flight mechanics, structural loads and aeroacoustics under power-on conditions.

In May, General Atomics Aeronautical Systems announced that it began wind tunnel testing for the MQ-9B Short Takeoff and Landing at the National Institute for Aviation Research in Kansas to assess aerodynamic performance, stability and control.

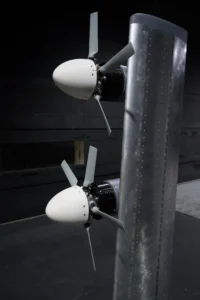

In May, Electra completed wind tunnel testing on a 20% scale model of the wing and rotors of its hybrid-electric EL9, a planned nine-passenger, short-takeoff-and-landing aircraft. Electra confirmed that its blown-wing design delivers the high lift required for takeoff and landing within 45 meters and that the approach and landing profile meets all FAA Part 23 safety and stall margin requirements.

In May and June, NASA tested a 2.13-meter semispan wing model with propellers in the 14-by-22-Foot Subsonic Wind Tunnel at NASA Langley Research Center in Virginia. Over 700 wing static pressures, total model loads and individual propeller loads were measured. The team collected data at different wing tilt angles, flap positions, propeller speeds, wind speeds and propeller positions. NASA plans to share information on its website once the data is analyzed.

In July, NASA and Lockheed Martin began taxi tests on the X-59 quiet supersonic aircraft at the U.S. Air Force’s Plant 42 in Palmdale, California. The taxiing marked the first time the demonstrator moved under its own power and represented the last series of ground tests prior to first flight in October. During testing, engineers and flight crews worked to validate systems including steering and braking.

Also in July, The Ohio State University Aerospace Research Center expanded the capability of the Large Area Reflected Shock Tunnel from Mach 6 to Mach 7. Researchers performed cold flow characterization in August, showing excellent mean flow uniformity and noise levels on par with other conventional hypersonic tunnels documented in the open literature. Between January and September, over 200 hypersonic runs were completed.

Also in July, the European Transonic Wind Tunnel in Germany performed the first wind tunnel test on an optimized, high-aspect-ratio wing designed within the German research program “virtual design environment for real, efficient engineering services.” Forces, moments, and discrete static pressures were measured at realistic flight conditions. Optical model deformation and pressure sensitive paint techniques provided additional data to compare to theoretical predictions.

In August, the German Aerospace Center (DLR) announced the completion of a two-week ground vibration testing campaign on the D328 UpLift research aircraft, which is intended to serve as a flying test laboratory for promising climate-compatible aviation technologies. The team installed 237 acceleration sensors at 153 measurement points to measure vibration frequencies, patterns and strengths while the aircraft was shaken on special supports that simulate being airborne. The data validated and improved simulations and could enable faster, more cost-effective airframe modifications for testing climate-compatible technologies.

In September, Ursa Major announced it broke ground in Weld County, Colorado, on a new 400-acre test and qualification site for its large-scale solid rocket motors, supporting current and future missile systems, and accelerating the path to production.

Contributors: Harald Quix, Jesse Little

Opener image: The DLR D328 UpLift research aircraft mounted on specialized shakers to induce flight-realistic vibrations and instrumented in preparation for ground vibration testing in August 2025. Credit: DLR

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.