Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

Designing and building life support systems for space stations requires a delicate balance of knowledge, safety and cost. As a handful of companies proceed with plans to develop their own stations to succeed the International Space Station, Jonathan O’Callaghan explores how they’re approaching the challenge.

When former NASA astronaut Janet Kavandi flew to space for the first time in 1998, she encountered a peculiar problem. During the mission, one of her colleagues floated over to a corner to grab a bag but, while there, suddenly started to feel lightheaded and nauseated.

The cause, as it turned out, was the air quality in the corner: “It had too much CO2,” says Kavandi. The crew member was fine once they moved away.

Kavandi, who was president of Colorado-based Sierra Space from 2021 to 2023 and now runs her own consultancy, cites the memory to me as an example of the complexities that must be addressed to keep NASA astronauts and other customers healthy and energetic aboard the coming class of privately owned and operated space stations.

The challenge is real, even if no one has ever died on a space station. There has, in fact, been only one deadly incident above the Kármán line, the internationally recognized boundary of space. When three Soviet cosmonauts undocked their Soyuz 11 spacecraft from Salyut 1, the world’s first space station, in 1971, they experienced a depressurization event prior to reentry and, upon landing, were found dead in their capsule. Aboard a station, one of the closest brushes with calamity occurred in 1997 on Russia’s Mir. A solid-fuel oxygen generator, also known as an oxygen candle, was triggered to provide supplemental oxygen through a safe chemical reaction but instead ignited. A 3-foot flame shot out of the canister for several minutes, and it took hours to clear the station of the resulting toxic smoke.

NASA knows these stories all too well, and that partly explains why for decades the agency has kept a careful account of its successes — and challenges — with the life-support systems on the International Space Station. But now, a seismic shift is coming. NASA, through its Commercial Low-Earth Orbit Development Program, plans to hand over the responsibilities of space station design and maintenance to the commercial industry in its entirety for the first time and shift to being a major customer of the companies that establish their own stations in low-Earth orbit.

Of course, these stations will have to meet certain high-level performance standards laid down by NASA before the agency is comfortable sending its astronauts and possibly other employees. And life support has been singled out as a chief concern.

“Our biggest worry point is environmental control and life support systems,” Jim Free, NASA’s former associate administrator who retired in February, said during a plenary talk at the AIAA SciTech Forum in January. He elaborated in a follow-up interview, noting NASA’s own struggles in developing life support technology across all its programs, not just ISS and the planned commercial stations.

“It’s difficult to build those systems,” he said.

So, what are the challenges involved, and how are companies coping? Let’s take a look.

Setting standards

We’ll start with the guidance that NASA has provided to the commercial station builders. In the 2023 CLDP-REQ-1130 document, short for “Requirement and Standards for the Commercial Low-Earth Orbit Development Program,” the agency laid out broad performance metrics. For example, the level of CO2 aboard the stations should not exceed 3,950 parts per million. However, how companies choose to design or procure their life support technologies — more formally called Environmental Control and Life Support Systems, or ECLSS, pronounced “ee-cliss” — to meet these standards is up to them.

“They’ll basically say, ‘If you want us to put astronauts on your [space station], you need to satisfy our safety, crew and life support teams that your system will be safe for our crew to use,’” says Brent Sherwood, a former senior vice president of space systems at Blue Origin, which is developing the Orbital Reef station with Sierra Space under contract with NASA. He notes that this is similar to how the agency structures its requirements for the Artemis lunar missions, as well as astronaut transportation to and from ISS under the Commercial Crew program.

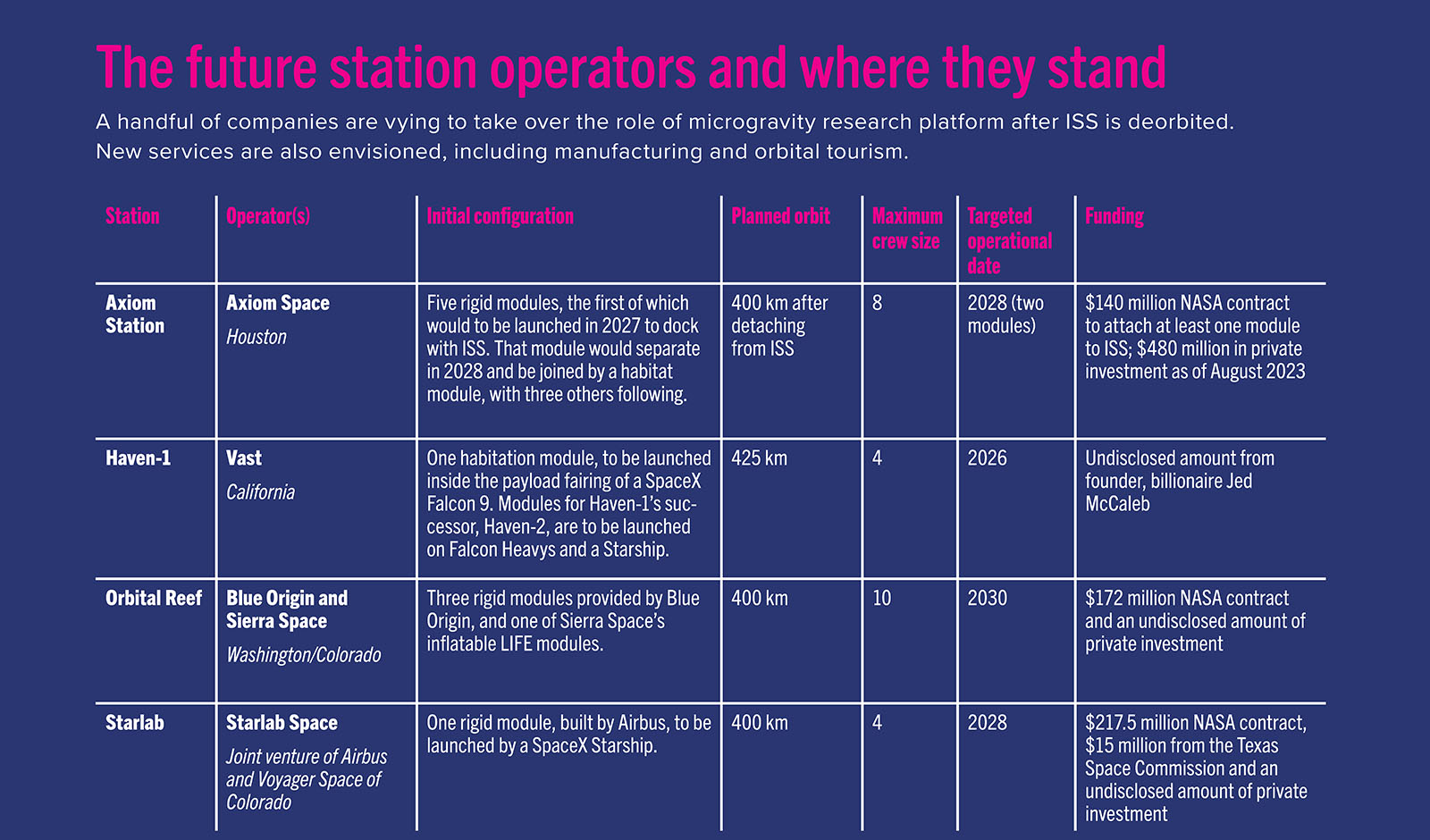

Each side has vested interests. NASA, which with its partners is making plans to deorbit ISS by early 2031, is counting on the commercial operators to pick up the station’s scientific legacy and maintain the continuous U.S. presence in orbit that began in 2000. Meanwhile, the host of aspiring station operators — including the three multicompany projects that NASA has awarded a collective $400 million — are counting on the agency to be their anchor tenant.

ECLSS refers to “basically all the things that you need to keep us squishy humans alive,” says Andrew Tidwell, a principal systems engineer at Northrop Grumman in Virginia who is also a lead engineer on the ECLSS for NASA’s planned Lunar Gateway station that the Trump administration has proposed canceling. The list includes devices to generate oxygen from water through electrolysis, recycle oxygen from exhaled CO2, turn urine into potable water and, of course, toilets and methods of storing food in compressed form.

There is some flexibility in how the commercial stations approach NASA’s standards, with the agency requiring “development and performance milestones to review and/or approve the selected provider’s progress toward system certification,” a NASA spokesperson told me in response to emailed questions. The agency did not make anyone from the Commercial Low-Earth Orbit Development, or CLD, Program available for interview.

The spokesperson said the process “will culminate in a certification review to provide evidence that the commercial space station, including the ECLSS, has met all NASA requirements and provide documentation of crew safety and mission assurance risks associated with the space station.”

Certification efforts are underway now, with some companies contracted under CLD already passing key milestones. Among them, Blue Origin and Sierra Space demonstrated they could recycle water from urine and identify contaminants in water. As of late 2024, plans called for beginning assembly of the Orbital Reef station in 2027 toward the eventual goal of sustaining a crew of 10.

“NASA provides us with a series of performance requirements,” says Shawn Buckley, Sierra’s vice president of destinations and in-space infrastructure. “We bring all that together and then create our master documents of our requirements.”

Station developers expect this performance-based approach will give them a freer hand during the design process. “Will we adopt all these standards, or relax some of them?” says Barry Finger, a principal systems engineer at Starlab Space. The Colorado company is a collaboration of multiple entities, including Airbus and Voyager Space, created to oversee the development of the Starlab station. Launch is targeted for sometime in 2028 aboard a SpaceX Starship, after which Starlab could host up to four crew members at a time.

“There might be a few areas where we try to push the envelope a little bit,” Finger adds. “But the truth is, to keep a human alive, it is a relatively small range of temperature, pressure, oxygen and CO2 levels. I don’t think we’ll deviate a lot from what NASA has already established on how the ISS operates day in and day out.”

Safety first

Of the many, many factors to consider when developing a life support system, one of the most important is potable water.

“NASA has a specification for what they’ll allow their astronauts to drink,” Finger says, including limits on “inorganic and organic contaminants.”

Even something as simple as using a piece of equipment comes with guidelines, such as the curvature of the object. “You don’t want a sharp corner,” says Finger, lest an astronaut or visitor get injured while moving around.

There are also more unusual standards, like the color of labels and indicator lights. “You don’t want to be showing the color red on an indicator light unless it really means something bad,” says Finger. But of the many challenges, perhaps none rank above toilets.

“It’s sort of legendary that toilets are challenging in microgravity,” says Sherwood.

Here, the stakes are about safety, not just the convenience of the crew. “The system has to work reliably for different body types while using minimal water,” says Anastasia Prosina, a California consultant for commercial space habitat development. “Even a small malfunction can become a major hazard. If a blockage occurs, it could lead to backup and potential leakage of waste material into the cabin environment.”

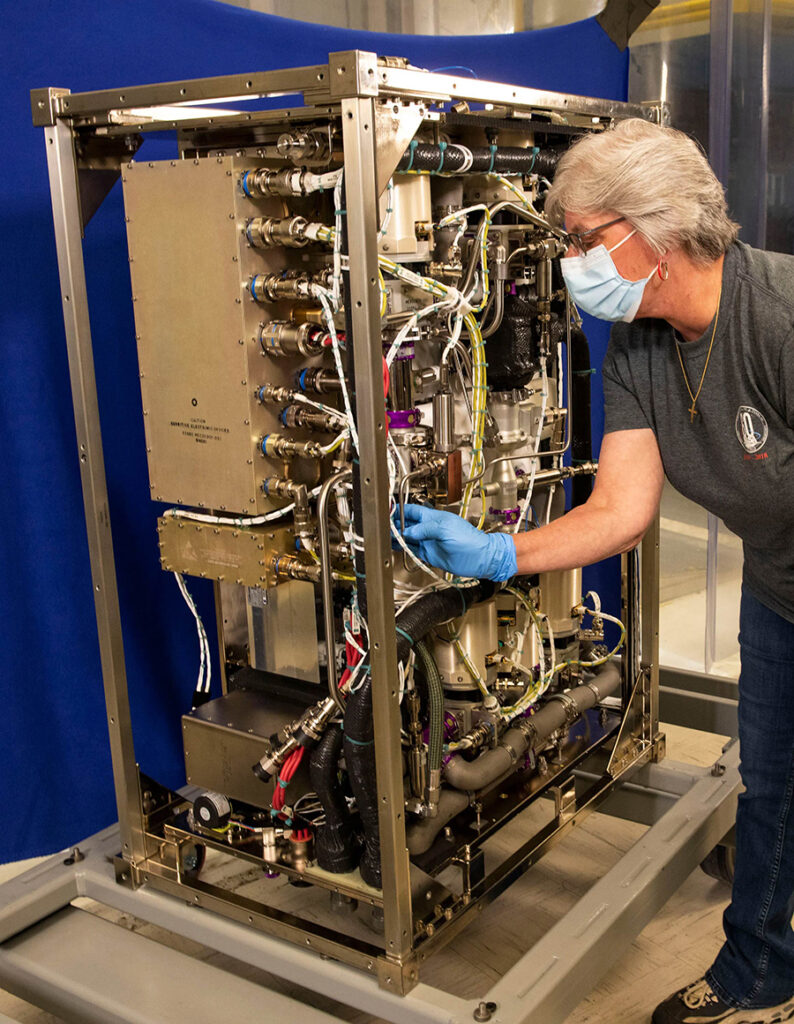

Credit: NASA/Fred Deaton

The maintenance and care of life support technology is also a challenge, says Finger, with multiple moving parts involved. As an example, he references how a certain historic spacecraft — which he declines to name — encountered an unforeseen issue with a water pump, despite the system being otherwise perfectly designed. “There was a gas bubble, and it lodged itself right where the impeller [a rotating blade] is,” he says. “And the blade just spun. It wouldn’t move anything. It wasn’t designed to pump air.”

Then there are other challenges that seem menial but are equally important to astronaut safety.

“There is bacteria, condensation buildup, the cleaning of everything,” says Buckley of Sierra Space. “How do you wipe down all of your systems? How much Velcro do you put on the space station, and where do you put it? And how do you pull the Velcro off so you don’t create a static discharge in a highly oxygenated environment? There are so many things that come into a life support system.”

The commercial station builders must also consider the costs of technology development to an extent that NASA hasn’t. “If we’re looking at private industry, they are trying to make a profit,” says Tidwell, the Northrop Grumman engineer. That might encourage companies to develop more of their components in-house to “own the cost,” he says, rather than buying off-the-shelf products.

“There are only so many companies that can survive making space-rated smoke detectors, for example,” he notes. “So you end up in this balance of where can we innovate on technologies to save us money, and where does it make sense to buy things commercial off the shelf. It’s a hard balance to find.”

Even then, finding the right off-the-shelf products can be difficult and require companies to get creative. “It’s not a big industry,” says former astronaut Kavandi. “Very few companies develop only for space-based environmental systems. So if there are filtration systems that airlines use, for example, they can take good ideas and apply them to space operations.”

New ideas

While humans have safely lived and worked in LEO continuously for 25 years, the coming class of stations provides an opportunity for fresh thinking.

“There is definitely room for innovation,” says Finger. “But you want to build on what’s been done in the past.”

For example, one alluring goal of spaceflight is to develop entirely closed-loop systems, meaning everything on a station would be recycled and reused. In this model, plants and other food would be grown aboard, allowing a station to exist without the continuous resupply flights that ISS requires.

“Currently on the ISS, you could claim it to be closed to maybe 80 to 90%,” says Max Haot, the CEO of Vast in California, which plans to launch a small station called Haven-1 to LEO next year. ISS reuses many commodities, including urine on the U.S. side for drinking water, “and it took a huge amount of effort to get to that efficiency,” he says — but it still doesn’t amount to a true closed-loop system.

Vast, which does not yet have NASA funding, also plans for Haven-1 to be open-loop, with many functions to be provided by the SpaceX Dragon capsule that will bring up the crew and dock with the station. To circulate air in the station — and prevent buildup of CO2 like the one encountered by Kavandi’s crew member — there is to be a ventilation duct between Dragon and Haven-1.

“Vast has been collaborating closely with SpaceX on the design, analysis, and testing of this duct to ensure the air will be properly exchanged,” Vast told me by email.

Dragon would also remove CO2 from Haven-1 and serve as the station’s humidity system and toilet. That will limit Haven-1 missions to “40 days of crew time for four people,” says Haot. For the company’s second station, the multimodule Haven-2, Vast plans to bring up more consumables to allow for stays of up to 720 days with each module.

Developing technologies to close more loops than is possible on ISS could be beneficial for more than just these commercial stations. The tech could be adapted or even used as is for eventual crewed missions to the moon or Mars, says Angelo Vermeulen, a space biologist and complex systems engineer at Delft University of Technology in the Netherlands.

“You can throw a lot of money at a very wasteful mission where people are living on Mars and every single molecule they need to eat is being shipped from Earth, but that’s just not sustainable,” says Vermeulen, who worked on the European Space Agency’s Micro-Ecological Life Support System Alternative project. “It’d be much better to use the resources that you have at hand.”

Manageable risk

Other improvements are possible: The station builders might also take a look at efficiencies in a way NASA hasn’t done before, says Buckley of Sierra Space. “Do you need all of the systems” that are on ISS today, “or can you reduce down the number of systems?”

Sierra plans to test some of the life support for Orbital Reef during uncrewed flights of its Dream Chaser spaceplanes, the first of which is scheduled to be launched to ISS later this year. The spaceplane’s life support systems are comparable to what will be used for Orbital Reef, says Buckley, including maintaining an atmosphere inside the spacecraft “that allows us to dock to the ISS.”

For the sake of reducing costs, operators might also consider lower risk thresholds than NASA has previously tolerated, says Mislav Tolusic, the chief investment officer and co-managing partner at Marlinspike, a venture capital fund based in Washington, D.C.

“There’s a huge risk aversion” in spaceflight, says Tolusic, adding that many of NASA’s standards have an extremely high bar. “I think we should revisit them,” he says. “Absolutely, we should.”

He points to a 2021 spacewalk that NASA postponed based on modeling that indicated the risk of the astronauts getting struck by space debris had increased by 7%. Tolusic says despite the seemingly high percentage, the overall risk remained incredibly low.

“The baseline risk of noncatastrophic penetration of a spacesuit is one in 2,700,” says Tolusic. “The probability of dying in a car crash over a lifetime is under 1 in 100. So that made zero sense to me.”

Despite the potential benefits, don’t expect commercial space station operators to rock the boat too much at first, considering the high stakes involved.

“Life support for humans is just so critical, so you want to build on what’s been done in the past,” says Finger of Starlab Space.

But there is certainly room for broader innovations in the future, as aspirations grow beyond Earth orbit. “The systems we’re designing today are focused on low-Earth orbit and the moon,” says Buckley. “I see those same systems being used as we go to deep space, to Mars and beyond.”

Acting Editor-in-Chief Cat Hofacker contributed to this story.

About Jonathan O'Callaghan

Jonathan is a London-based space and science journalist covering commercial spaceflight, space exploration and astrophysics. A regular contributor to Scientific American and New Scientist, his work has also appeared in Forbes, The New York Times and Wired.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.