Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

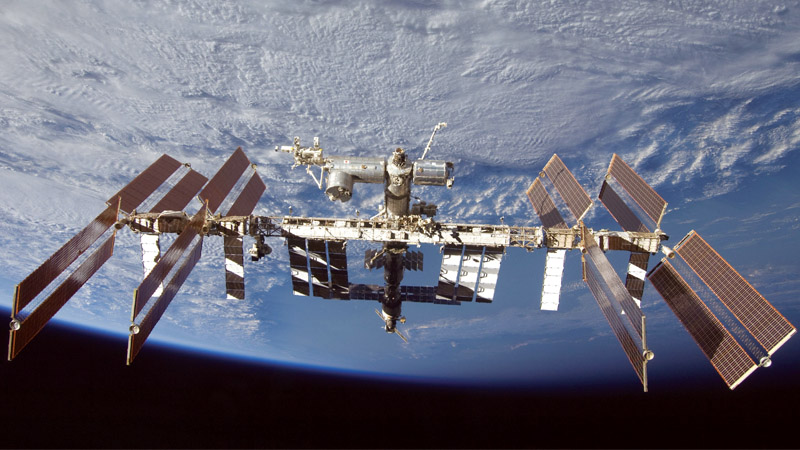

Lessons for exploration from the International Space Station

A tremendous amount of real-world testing, fit checks and collaboration between American and Soviet engineers occurred in preparation for the 1975 docking between an Apollo Command Module and a Soyuz. An adapter was required between the two spacecraft to accommodate their very different docking mechanisms. The Soviet Union had its APAS, or Androgynous Peripheral Attachment System, and NASA had the Apollo Probe and Drogue docking system.

The International Space Station assembly was verified in a much different fashion. U.S. and international partner engineers conducted very few one-on-one fit checks on the ground before joining the major elements in space. The pieces came together well, and to casual observers, the assembly probably looked easy.

In reality, that success was hard earned, as I know from my years as lead of the assembly analysis team from 1996 to 2014. I believe it’s important to share information about how the station elements were constructed and assembled in low Earth orbit, because this complex program is the best model we have for the kind of international cooperation and technological integration that we’ll need for human missions to cislunar space — the region near the moon — or near Mars.

Reliance on computing

We attached, depending on the count, about 40 major discrete modules and structures to create a spacecraft with a habitable volume of about 915.5 cubic meters. We could not have feasibly fit tested each piece, so the U.S. segment instead relied heavily on master tooling and computer aided design, CAD, to verify the initial assembly. The success of this approach can be attributed to simulation and modeling technology, plus some luck. My late father posted a sign in his garage that said, “Funny — hard work and good luck seem to go together.”

Behind the scenes we worked fervently to ensure a safe and uneventful assembly. It’s astonishing to me that the End to end Berthing Integration Team, EBIT, made the assembly of ISS appear as simple as snapping a plastic toy together. That massive effort required a great deal of behind-the-scenes coordination and communication among EBIT members, who represented all the major stakeholders in ISS assembly: Astronauts or their proxies, astronaut trainers, representatives for structures and mechanisms and robotic-arm experts. Additionally, we had a team called MAGIK, short for Manipulator Analysis Graphics and Interactive Kinematics, as well as lighting experts and me. The MAGIK guys performed 3D CAD analysis with medium-fidelity models to determine how to get the payload from the payload bay to the preinstall position (60.96 centimeters from the fully berthed position). I performed 3D computer simulations with very detailed high-fidelity CAD models of the interface to verify there were no interferences to the on-orbit assembly of the major elements of the ISS from the pre-install position to fully berthed position.

Leadership

In 1966, at the peak of its funding, NASA received four cents of every dollar in the federal budget. Today, it receives about half a penny of every federal dollar — not pennies on the dollar as some politicians have claimed.

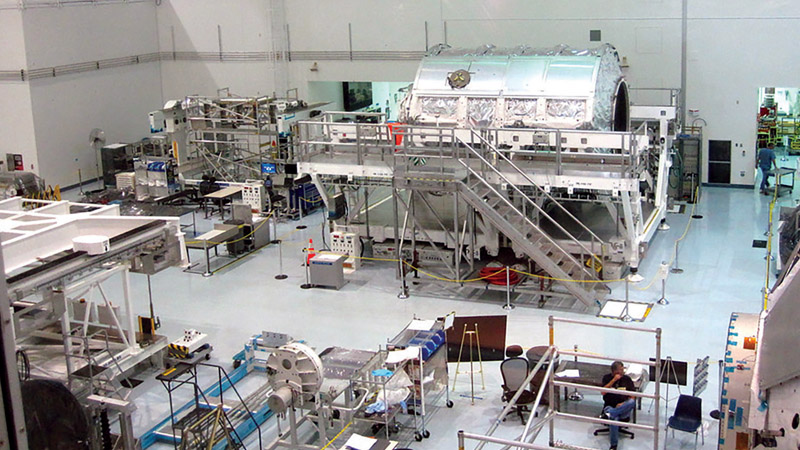

In an ideal world, we would have built the ISS, assembled it on the ground, tested it and then taken it apart and launched it and assembled it again on-orbit. We did not do that. It is almost absurd to think of the ground support equipment required to do such a thing. It would have been difficult, time consuming and expensive. So leadership decided to fast track the program. We started launching hardware to orbit before hardware that was going to attach to it had been built yet or even designed.

The station was built with a swarm mentality, with the program sometimes changing directions as swiftly as a throng of bees. It is usually not easy to pinpoint which individual initiated the change, but the group changes direction nonetheless.

On ISS, the need for a change order could originate from anywhere within the organization. The top management might cancel a planned module, as was the case with the Centrifuge Accommodation Module (used for experiments with variable gravity using a centrifuge as well as a major source of stowage volume) or a worker bee like myself might find an issue that would require an unanticipated operational workaround or redesign, or even removing hardware on-orbit.

Take, for instance, the space station’s cupola, a bay window robotic workstation. When the space shuttle program was canceled in 2011, NASA decided to launch the cupola attached to Node 3, because there would be no shuttle flight available for the cupola as planned. That meant attaching the cupola to the Node 3 axial port, instead of attaching it one of the radial ports as designed. Picture a cylinder. An axial port would be on either flat end of the cylinder; a radial port would be on the curved part of the cylinder. I performed analysis to determine how Node 3 would need to be modified to fit the cupola and then be de-berthed and attached to a Node 3 radial port. Precision digital preassembly measurements were then used to guide the delicate ground installation, using a repurposed pressurized mating adapter piece of ground support equipment and a six degree of freedom translation table. In plain English, we used a work stand originally intended for the Pressurized Mating Adapter and used it to support the cupola while we installed it with a six degree of freedom (roll/pitch/yaw/X/Y/Z) translation table.

The swarm mentality stems in part from dealing with international partners with individual agendas as well as the inherent technical uncertainty of such an audacious integration endeavor. It was akin to assembling an airplane while it is rolling down the runway.

We did not know exactly what the ISS would turn out to be, and it turned out to be different than what we anticipated. We changed our minds along the way and are still changing our minds. We launched the Permanent Logistics Module, or PMM, and installed it on the ISS to compensate for the loss of about 45 percent of the storage space we incurred when we canceled the centrifuge. Then, we changed our mind and moved it to another location in order to allow for more visiting vehicle access to the nadir, or Earth-facing ports. The PMM was not in the original game plan but the centrifuge was. It was a contribution from Japan and had actually been built.

Technical challenges

We encountered and overcame almost every conceivable obstacle: language barriers, cultural differences, multiple time zones, incompatible measurement units, and different software and software fonts.

The station experience demonstrated that it’s much cheaper to fix a problem in the conceptual phase than in the design, manufacturing or operational phases. In order to most efficiently fix problems in the conceptual phase, team collaboration is critical. In planning future exploration, for instance, it would be wise to have astronauts and engineers and scientists and operations people talk to each other from the beginning.

The CAD environment is an ideal one for virtually verifying and optimizing the design. Doing that on a large scale ideally requires creating all CAD models in the same software and coordinate system for analysis and simulation.

Simulation in the conceptual and design stage is not enough. A strong leadership team needs to keep things on schedule and minimize change orders during production and operation. Equally important is the management team below that level, working the front lines of integration to flag potential issues as soon as possible. You want to nip problems at the lowest pay grades, but you also need an effective method to elevate issues up to management.

Our space station teams, including the End to end Berthing Integration Team and those working on digital preassembly and cable and fluid assessment groups, served as objective third party “referees” who bridged the gap among contractors. What we brought to the table was an independent assessment, with the perspective of the big picture, and the expertise and familiarity with both sides of each interface in minute detail. Our team had strong support from NASA management and the astronaut corps. A similar integration team structure might be beneficial to any large-scale integration effort, especially one involving numerous contractors and international partners.

Murphy’s Law, paraphrased

If it can go wrong, it will, at the worst possible time, especially in the space business.

Ways to mitigate Murphy’s Law are to be ready early, know what you are doing and practice it. Also know what you will do if something goes wrong and practice that.

We followed that procedure. The result is that we made the assembly at least look easy. But it was harder than it looked, and it’ll be the same for getting into cislunar or deep space.

As humans, we are hard wired to explore. We have always wondered what is over that next hill, across that lake, on the other side of that ocean. Deep space is our next ocean. We should remember the sailing lessons learned from the ISS program.. ★

Space innovation through cooperation

International cooperation in space provides a stimulus for technological innovation similar to war, but without the devastating toll. To paraphrase John F. Kennedy, it serves to focus our efforts. Multinational human spaceflight, in particular, brings out the best in us. Expanding cooperation for missions beyond low Earth orbit is likely to bring diplomatic benefits as well as technical breakthroughs. We’ve known this since the Apollo days. For a moment at least, the world was unified in wonderment at the feat of landing on the moon. Technology-wise, the series of missions spurred the miniaturization of electronics that paved the way for the revolution of personal computers and smartphones. — John Cook

About johncook

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla aliquet, libero sit amet egestas imperdiet, tortor nunc molestie lorem, ut venenatis nisl augue sed sapien. Aenean at aliquam lacus, vel laoreet nisi. Proin in malesuada quam. Praesent ultrices consectetur accumsan.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.