Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

What it will take for reusable rockets to revolutionize access to space

No one, not even SpaceX, is ready to write an epitaph for expendable rockets, which have shouldered the vast majority of some 5,700 orbital launch attempts since a modified Soviet intercontinental ballistic missile lofted the first Sputnik satellite 60 years ago. Instead, SpaceX and others are incorporating reusability into today’s expendable rockets or the blueprints for next generation versions to find out just how far the trend can be taken.

The Hawthorne, California, company this year completed two commercial satellite launches with Falcon 9 first stages that previously landed on drone ships. During November’s debut of the Falcon Heavy, SpaceX will try to land the core stage and two strap-on first stage boosters. The company is also actively wooing its customers with earlier launch dates and small discounts if they choose to fly on a rocket containing used components.

Competitor United Launch Alliance, a joint venture of Boeing and Lockheed Martin, has embraced the concept of reusability for its forthcoming Vulcan rockets by proposing to recover spent stages via helicopter. “As we develop the technology and use it in the marketplace, we’re going to find out who’s right. That’s kind of the beauty of competition,” says Tory Bruno, the CEO of ULA.

In Europe, ArianeGroup (formerly Airbus Safran Launchers) wants to someday fly back first stage engines for runway landings and reuse them.

If SpaceX and these competitors succeed, the result could be dramatically reduced space transportation costs, an aspiration that dates back to the space shuttle days. Technological and business hurdles lie ahead, though, including whether the U.S. Air Force, which is responsible for delivering the country’s military and spy satellites safely to orbit, can be convinced to trust the technology.

Ambitious plans

Ultimately, SpaceX aims to recover and relaunch much more than the Falcon 9’s first stages, which account for about 70 percent of each rocket’s cost. The company wants to recover the payload fairings and second stages, as well as Falcon 9 and Falcon Heavy core stages. Unlike the reusable parts of the space shuttle, which were refurbished and reflown only after months of painstaking, labor-intensive and expensive work, SpaceX chief executive and lead designer Elon Musk wants his team to recover, refuel and relaunch a Falcon within 24 hours.

Not to be outdone, ULA, which is targeting a 2019 debut of Vulcan, wants the booster’s two main engines to separate after shutdown and parachute back through the atmosphere for a midair helicopter recovery, saving the company about 65 percent of the rocket’s cost, says Bruno. Whether either approach will prove economically viable and reliable — especially for U.S. government launches — remains to be seen.

Musk, who founded SpaceX in 2002, exuded confidence in a July speech in Washington, D.C. “I think we are entering a new era of space exploration, which is extremely exciting,” he said at the International Space Station Research and Development conference. “It’s not just SpaceX,” he said. “There’s a number of other companies that have developed new approaches.” But he said the “biggest thing” to happen “is the landing of the Falcon 9 rocket booster.”

Luxembourg-based SES bought the first ride on a previously flown Falcon 9. The company has been upbeat since the March launch of its SES-10 communications satellite. “When you go to the airport you don’t ask if it’s a new Airbus or a new 777. You get on it and you fly. It’s a service that is being offered and you know the reliability of the vehicle is such that it’s safe. I think that’s where we’re headed. It’s not going to happen overnight, but I think that within 24 to 36 months you’re going to see this,” says Martin Halliwell, the company’s chief technical officer.

The Air Force and NASA, the two biggest customers for U.S. launch services, are beginning to mull what inspections, tests and risk assessments they will need to certify used rockets are safe for reflight. The Falcon 9 first stage, like most aerospace structures, is made of aluminum alloy. During atmospheric re-entry, the lower part of the 14-story tall booster experiences extremely intense heating, which can change the mechanical properties of the metal. “How do you make sure that you haven’t heated this aluminum structure up so that it will fail the next time? I’m sure SpaceX has some inspection technique, but there are all kinds of technical challenges like that,” says Wayne Hale, a former shuttle program manager who serves as director of human spaceflight at Special Aerospace Services, an engineering consultancy.

So far, the Air Force and NASA have certified only new Falcon 9s for flight. “I don’t view reuse for the near-term,” says the Air Force’s Claire Leon, who oversees launch service acquisition under the Evolved Expendable Launch Vehicle program, which has been dominated by ULA’s Atlas 5s and Delta 4s but now includes two contracts with SpaceX. “For us to use reused hardware — or flight-proven hardware as SpaceX likes to say — we would have to go through a whole nother certification process and we’re just getting through the initial certification process, so it’ll take another increment of joint effort between us and any contractor that’s proposing reuse,” she says.

The Air Force does intend to study how to certify for reuse, she adds. “It’s very important for the Air Force. We really are trying to reduce the cost of launch, so if this is the offering from commercial providers, then we need to get onboard, we need to figure out how to do that. It’s just going to take us a little more time, but it is something that we are starting to study.”

NASA grappled with shuttle reusability for 30 years before ending the program in 2011. Each orbiter’s three liquid-fuel main engines was designed to fly 10 times before inspections were necessary. However, during ground tests engineers discovered parts in the pumps that needed to be checked after every flight. So for the first 20 years of the program, the engines, built by Aerojet Rocketdyne, were removed between flights so the pumps could be taken out and sent back to the factory in California for inspections. Sometimes the pumps were torn down, then shipped to NASA’s Stennis Space Center in Mississippi and hot-fired to make sure they had been put back together properly. The engines were then returned to the Kennedy Space Center in Florida and installed into an orbiter.

“Toward the end of the program, we got to the point where the engines could fly a couple of times, but we never got to 10,” Hale says.

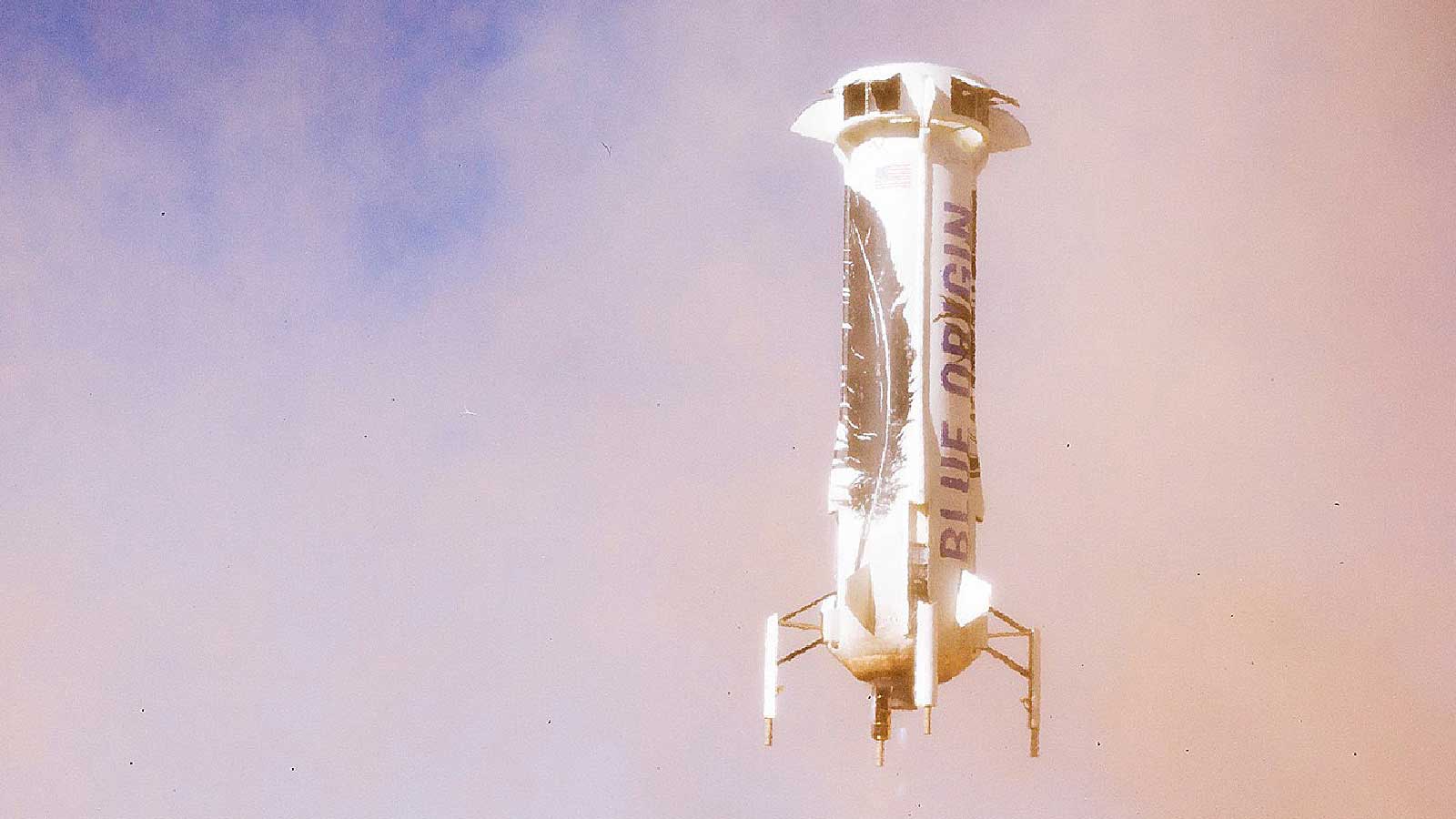

That won’t work in today’s competitive market. “If you have to dissemble the vehicle after every trip, X-ray all the parts, put it all back together, that is not real reusability. It has to be aircraft-like reusability. And it’s going to be hard to get there,” noted Jeff Bezos in his June acceptance speech for the Collier Trophy for New Shepard, a reusable suborbital spaceship developed by his space company, Blue Origin.

Former shuttle launch director Michael Leinbach warns that reusability has a hidden cost, which might not surface for years. “There is a natural human tendency to start accepting a little bit of creep in problems with reusing the same vehicle. A minor problem may become a moderate problem and then it might become a major problem. It is very difficult to get over the natural tendency to say, ‘Well, it didn’t hurt us last time. It won’t hurt us this time.

“Most of the high-energy systems are operating almost right at the edge of failure every time,” he adds. “When you look at SpaceX’s rocket when that thing jettisons the payload and then it fires its engines again and turns around and flies in its own exhaust to reverse momentum to get back toward the Cape, those are very, very difficult environments to deal with. To me, they are going to get into reuse issues where they’re going to talk about minor issues that occurred during the previous flight,” Leinbach says. “People are going to accept minor deviations where maybe they shouldn’t. My counsel would be, when the hardware starts talking to you, pay attention to it.”

Try, try again

SpaceX initially tried to recover its Falcon 9 first stages by parachuting them into the ocean, but the aerodynamic stress and heating of plowing into the atmosphere proved too taxing. The company switched to a propulsive landing technique and practiced with a suborbital rocket called Grasshopper. It also began experimenting with its orbital rockets’ first stages, which conducted engine burns to reduce re-entry velocity and hover vertically over the ocean before succumbing to a hard splashdown.

SpaceX then attempted landing on a drone ship floating in the ocean, failing twice before finally returning a booster intact in December 2015 with a touchdown on the ground at Cape Canaveral Air Force Station. By July 2017, SpaceX had accomplished the feat either on the ground or on a drone ship a dozen more times. It returned two of those boosters to service, dispatching SES-10 into orbit in March and BulgariaSat-1 in June for Sofia-based BulgariaSat. Four more pre-flown boosters were due to launch before the end of the year.

In his July speech, Musk said SpaceX would start reflying its Falcon boosters within 24 hours “probably by next year,” and he gave a glimpse of the company’s strategy. “The key,” he said, “is that all you do is inspections, and no hardware is changed, not even the paint.” The company also aims to recover its payload fairings, which cost around $6 million, and eventually will attempt return of its upper-stage boosters as well, Musk added.

SpaceX is still working off a backlog of business that piled up after a September 2016 launch pad accident, which grounded Falcon flights for four months. Two of those customers, SES and BulgariaSat, say they were offered earlier launch opportunities if they agreed to fly their satellites on recycled boosters rather than new ones. SES-10, which launched in March, would have been delayed at least another three months if it had waited for a new rocket, says SES’ Halliwell. In May, the satellite entered commercial service, adding an estimated $2.2 million per month in revenue to the company’s coffers. “It’s been cash out essentially for the last three and half years. It’s good to turn the corner,” he says.

SpaceX, which lists the base price of a Falcon 9 rocket at $62 million, offers customers a slight discount if they opt for a pre-flown booster. But if the company can learn to recover and reuse more than just the rocket’s first stage, the goal would be to shave prices by about 30 percent, says SpaceX President Gwynne Shotwell. First though, SpaceX needs to recoup its investment in the landing technology, which Musk pegs at about $1 billion.“I want to see more reaction on the price points,” says Halliwell. “I don’t think anybody, including SpaceX themselves, really understands what the pricing is going to be longer term.”

Whether launch price cuts will pave the way to a renaissance in space is unknown. Satellite services, manufacturing and ground equipment accounted for $255 billion in annual global revenue in 2016, according to a Satellite Industry Association report released in June. The space launch industry’s worldwide revenue was about $5.5 billion.

“The cost of launch is not driving the industry,” says Carissa Christensen, founder and chief executive of Virginia-based Bryce Space and Technology. “Coming up with $100 million upfront for a launch is not trivial, it’s very capital intensive, but even if you reduce launch costs to zero you’re not going to see five more direct-to-home TV satellite ventures launching.”

Cheap access to space, however, might pave the way for a new low Earth orbit economy that includes asteroid mining, commercial space stations, tourism, and off-planet workers and residents, but it likely will be decades before any of those ventures are economically viable, Christensen adds.

The passionate billionaires

The wildcard in the new space economy is what Christensen calls “the passionate billionaires” — people like Musk, Amazon founder Bezos, Virgin Group’s Richard Branson and Microsoft’s Paul Allen — who have invested personal fortunes in launch companies. “These are not simply hobbies,” she says. “But the motivation for investment, the magnitude of the investment and the duration of the investment is driven by their passion and their vision, as opposed to a financial tradeoff. It’s really interesting how it is driving the economics of reusable launch.”

Like SpaceX, Bezos’ Blue Origin bases its rocket designs and business plans on reusable hardware, beginning with the New Shepard launch system, which is undergoing unmanned test flights. Bezos said company astronauts and engineers could begin flying before the end of this year, followed by paying passengers in 2018. New Shepard, which launches from Blue Origin’s West Texas spaceport, is designed to autonomously fly up to six people to an altitude above the Karman line, 62 miles (100 kilometers) above Earth. From that vantage point, passengers will be able see the curvature of the planet set against the black sky of space and experience a few minutes of weightlessness. Blue Origin also is working on an orbital-class rocket called New Glenn, which it says will debut in 2020, launching from Cape Canaveral. The company has disclosed six launch contracts for New Glenn, one for Eutelsat and five for startup OneWeb, which is developing a constellation of low Earth orbiting satellites for global, high-speed internet services.

Branson’s California-based Virgin Galactic plans to fly tourists, researchers and payloads aboard reusable air-launch winged suborbital space planes collectively known as SpaceShipTwo. The fleet is expected to fly from New Mexico’s Spaceport America. Another Virgin company, Virgin Orbit, marries the air-launched system with an expendable rocket to deliver small satellites into orbit, with a debut launch expected this year. Allen’s Stratolaunch envisions similar services, but on a much grander scale, using a mammoth jet that can carry payloads up to 250,000 kilograms. The airplane is undergoing testing in Mojave, California. For now, Stratolaunch is not focused on human spaceflight.

With their deep pockets, investor allure and independence, the billionaire rocketeers have presented a challenge to United Launch Alliance and Europe’s Arianespace launch services company. “Everybody is trying to play catch up with SpaceX,” Teal Group senior analyst Marco Caceres said at a launch industry seminar in June. “The Europeans are scared to death. Boeing and Lockheed, I think, are scared to death because there is just no way that they can develop and deploy launch vehicles that are going to be able to offer prices anywhere close to what Falcon 9 offers and still make a profit,” he said. He predicted that Falcon 9 will “get cheaper and cheaper and cheaper as it becomes more reusable.”

With their decades of experience, the old guard has no intention of walking away. Arianespace is making plans with prime contractor ArianeGroup to field a fleet of Ariane 6 expendable rockets meant to lower launch costs, whether or not they include reusability initially. For the longer term, Arianespace is considering reusable technologies, including ArianeGroup’s proposed reusable engine Prometheus, and Adeline, a conceptual winged rocket stage that would sprout propellers and landing gear to carry an engine down to a runway for reuse. “The question is what is the best solution for the future? We do not really know right now — nobody knows,” says Jan Woerner, director general of the European Space Agency, which is investing about 2.9 billion euros ($3.3 billion U.S.) in the Ariane 6 program.

United Launch Alliance not only is battling competition from SpaceX and Blue Origin but also an export ban on the Russian engines that power its workhorse Atlas rockets. To address both concerns, as well as retire the pricier Delta 4 line, ULA is developing the Vulcan to have recoverable first-stage engines and an upper stage that can be repurposed for a variety of transportation needs in orbit. “They become the trains of cislunar space … like a trucking fleet,” says ULA’s Bruno.

In the background of the reusable rocket debate are NASA and the U.S. Air Force, the biggest buyers of launch services in the United States. Both have taken advantage of SpaceX’s cut-rate Falcon 9 prices — SpaceX will launch a GPS satellite for 40 percent less than what ULA charged, for example — and both see reusable rockets in their future.

NASA is considering previously flown Falcon boosters for SpaceX cargo runs to the International Space Station, said William Gerstenmaier, associate administrator for human exploration and operations. And Gen. John “Jay” Raymond, head of Air Force Space Command, said in April he is open to the idea of flying military satellites on recycled rockets. For now, however, a draft solicitation for military launch services beginning in 2022 still calls for “evolved expendable launch vehicles,” or EELVs. “We’ll have to figure out what to do with that extra ‘E,’ ” quips SpaceX vice president Hans Koenigsmann. “We’ll have to rename it. Maybe ‘extraordinary’?”

Staff reporter Tom Risen contributed to this report.

“We’re going to find out who’s right. That’s kind of the beauty of competition.”

Tory Bruno on ULA’s strategy for reusability compared to SpaceX’s

About Irene Klotz

Irene has covered space for 30 years, with particular focus on commercial space and the search for life beyond Earth. She joined Aviation Week & Space Technology in July.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.