Bending the cost curve

May 2022

SpaceX’s breakthroughs in reusability sprang from the lessons of history. The coming Starship space launch attempt portends an even more profound lowering of launch costs in the years ahead. Phil Moynihan and Eugene Ustinov share their analysis.

The desire for low-cost access to space has been the dream of all spacefaring nations since the launch of Sputnik I in 1957. It’s that brass ring that everyone reaches for. It’s the holy grail that’s always just over the horizon.

While nations and commercial companies have taken evolutionary steps toward that end over the decades, especially in recent years, they have so far fallen short of a true paradigm shift that would bend the cost of launching heavy payloads downward to a revolutionary degree.

Enter SpaceX, which plans to fly its reusable Starship design on its first orbital flight, possibly in May. This will be the first end-to-end test flight of the two-stage rocket consisting of the Super Heavy booster and Starship upper stage that would eventually carry astronauts and even tourists. If all goes well, the flight will demonstrate just how different this heavy-lift rocket is from all those that came before it.

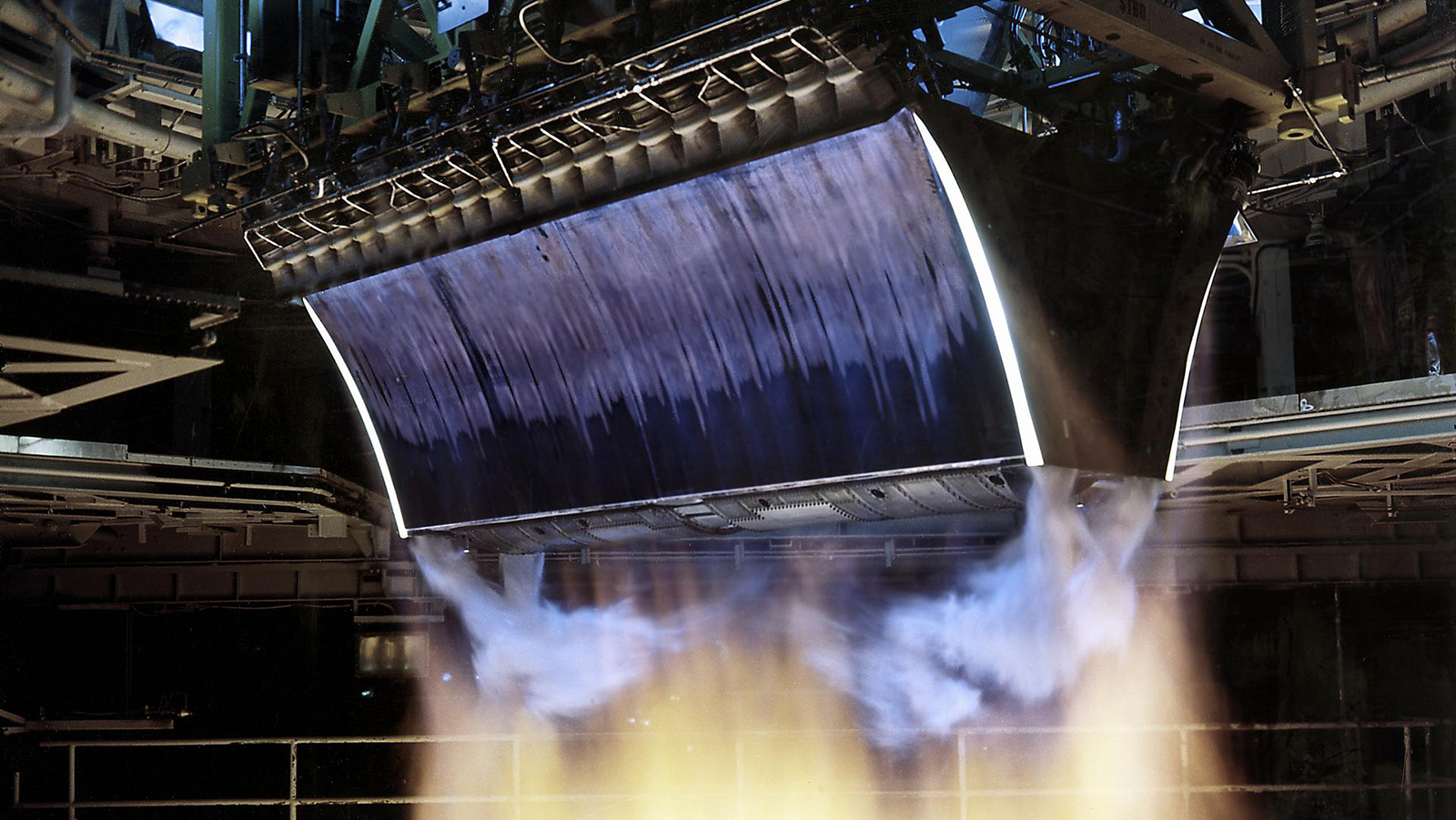

After blasting off from Boca Chica, Texas, Super Heavy’s 33 Raptor engines will boost the unoccupied Starship on its way to orbital altitude and then separate and descend with the aid of its liquid-methane-and-oxygen-fueled engines for what the company vaguely calls a “soft landing” in the Gulf of Mexico. This would be in contrast to Elon Musk’s description of Super Heavy someday returning to Boca Chica to be caught by the chopstick-like arms of the “Mechazilla” recovery tower now under construction. Once separated from Super Heavy, Starship will continue on toward orbital altitude, propelled by six Raptors, and once at that altitude, cut off its engines and begin an unpowered decent toward the Pacific Ocean. This will involve a technique demonstrated by a series of prototype flights in 2020 and 2021 in Texas in which the Raptors reignited to flip the craft base first. This time, though, Starship will attempt a soft landing northwest of Kauai in the Hawaiian islands. SpaceX has not specified whether plans call for a splashdown or landing on some kind of vessel. FAA filings indicate that SpaceX may not recover the Starship and Super Heavy from the first flight, but operational plans call for reflying them.

If the test launch succeeds, it will represent a key step toward bending space access cost downward to a revolutionary degree. Demonstrating that expensive components can be returned to Earth will likely inspire other companies to adopt reusability.

The space community’s path over the decades to reach this point has been wrought with brambles, blind corners and dead ends, but it’s a fascinating history.

It all began when the Apollo lunar missions of the 1960s and early ’70s generated excitement about space travel but also confirmed that continuation of single-use throwaway vehicles for space access was not sustainable. Just over a year after the historic Apollo 11 landing, then-U.S. President Richard Nixon decided to truncate the original plan for 10 lunar landings, making the last mission Apollo 17 in December 1972. Astronauts had experienced a brush with death in 1970 during the Apollo 13 mission, and even the truncated program ended up costing $25.4 billion, nearly $165 billion in today’s dollars.

In January 1972, Nixon directed NASA to build a reusable spacecraft to ferry people and cargo to low-Earth orbit and back. The space shuttle design NASA selected in March of that year became the iconic architecture now recorded in history: On ascent, a reusable orbiter would receive fuel from a large expendable external tank, plus additional thrust from two solid rocket boosters whose cases would be fished out of the sea and reflown.

In the following years, NASA sought to drive launch costs down by encouraging the private sector to develop its own launch vehicles. Although NASA had been contracting with commercial entities since its inception in 1958, it had treated these sources more as vendors for needed parts while retaining absolute control over all aspects of its programs — a process that had proved costly. So in 1983, then-President Ronald Reagan signed National Security Decision Directive-94, “Commercialization of Expendable Launch Vehicles,” which initiated greater commercial involvement in launch vehicle development. NASA also established the Office of Commercial Programs in September 1984 to encourage the private sector to become even more involved in space activities. That year also saw Congress pass the Commercial Space Launch Act for the sole purpose of inspiring industry to design and build their own launch vehicles.

The space shuttle Challenger tragedy in 1986 accelerated the push toward commercial development of expendable launch vehicles and encouraged commercial enterprises to advocate for a more active role. And while Reagan temporarily banned commercial payloads from flying on shuttle flights after the Challenger loss, that hiatus did not preclude private companies from actively developing their own expendable launch vehicles for those customers.

On the reusable front, research received a significant boost from the dissolution of the Soviet Union in 1991 and the ensuing end of the Cold War. The reason: The excess government dollars or “peace dividend” provided a new opportunity for longer-term research. With NASA funding, various aerospace companies began experimenting with different launch vehicle concepts in support of NASA’s desire for assured access to space, specifically focusing on conventional propulsion systems that would launch two stages to orbit. Early participants were Boeing, Lockheed Martin and Orbital Sciences Corp., subsequently bought by Northrop Grumman.

A small victory for partial reusability came in 1990 with the first launch of Orbital’s Pegasus air-launched rocket, in which a modified Lockheed L-1011 airliner carried the rocket and payload to an altitude of 40,000 feet and released them. Although limited to payloads of 454 kilograms, the design was a significant step toward a revolutionary paradigm shift in launch capability and demonstrated the significant cost savings of a multiuse vehicle.

A motivator for this work was that the space shuttle fleet had not succeeded in reducing launch costs as hoped. Furthermore, each orbiter required more refurbishment between flights than originally hoped.

So in an attempt to provide an alternative to the space shuttle, NASA in 1996 awarded Lockheed Martin a contract to develop the X-33, aiming for a single-stage-to-orbit vehicle powered by a linear aerospike engine, a design notable for its lack of a conventional nozzle. If all went as planned, the X-33 would avoid costly launch vehicle staging. But after the program experienced a long series of technical difficulties — including weight growth and evidence that the vehicle would experience flight instability if it ever took to the air — NASA canceled the effort in 2001 without ever flying the demonstrator.

The troubles experienced by the X-33 developers suggest to us that at least two launch stages comprising conventional propulsion, as in the Starship design, remain required for a truly cost-effective vehicle. Matters may change someday, but not today.

The experience gained from these earlier efforts stimulated a wider commercial participation. After extensive lobbying by the aerospace industry, in November 2005, NASA established the Commercial Crew and Cargo Program Office, C3PO, for the purpose of encouraging growth of the private spacecraft sector, which in turn established the Commercial Orbital Transportation Services program, COTS. Although C3PO managed COTS, NASA itself backed off from its normal hands-on approach and assumed the role of an investor and adviser to nurture development of commercial space transportation systems.

This was a new way of doing business, in short a new paradigm. The newness was NASA becoming a partner with industry and not its overseer — all for the purpose of reducing costs for space access, although the focus was still not on reusable space launch vehicles. COTS created a pathway for the Commercial Crew Development program to establish astronaut-ferrying services to and from the International Space Station. Awarding contracts to Boeing and SpaceX in 2014 to provide those services marked a milestone toward restoring U.S. ability to reach ISS with American-made rockets.

This renewed commercial focus freed NASA to concentrate its in-house propulsion funds on research for advanced in-space propulsion, such as electric propulsion that’s capable of delivering very high specific impulses. Development of space access capability itself was left to the efforts of commercial enterprises.

All of these commercialization efforts to reduce the cost per kilogram of reaching space, while significant, still remained evolutionary. None of these addressed the “elephant in the room” — the need for a given launch vehicle to be flown multiple times and for such reusability to become the norm across the launch industry. The logic was inescapable: No one would build a 747 aircraft, fill it with passengers in Los Angeles, fly it to New York and then throw it away. The only way to bend the space access cost curve in a revolutionary way is through the multiple use of the same launch vehicle.

The vertical launch and landing technology adopted by SpaceX and Blue Origin was inspired by development of two Delta Clipper-Experimental, or DC-X, low-altitude demonstrators. The U.S. Air Force provided early funding, but the program was later transitioned to NASA. McDonnell-Douglas started construction of the first vehicle in 1991 and flew it for the first time at White Sands in New Mexico in 1993. The DC-XA, as the second vehicle was called, made the program’s final flight in July 1996, when it reached an altitude of 3,140 meters. Although the program ended, its influence on the industry did not.

Various concepts of reusable launch vehicles began to arise, most notably from Blue Origin, Northrop Grumman, SpaceX and United Launch Alliance. SpaceX, however, emerged as the clear leader toward reaching this goal. SpaceX has relied heavily on clever reconfiguring of existing technology and has funded the vast majority of Starship development with its own internal resources. NASA, however, has become a very effective partner to SpaceX by funding needed high-risk development along the way, most recently awarding a $2.9 billion contract to build a lunar lander version of Starship that the agency would certify.

An exception to the push for reusability has been NASA’s development of the Space Launch System moon rockets, initiated in 2011 with a contracting team. Unlike Starship with its Super Heavy booster, SLS’s core stage won’t be recoverable. Given that NASA expects the early SLS launches to cost $4.1 billion each, the agency is missing an opportunity to save billions of dollars through reusability.

In an attempt to establish leadership in multiple-use launch systems, SpaceX after three attempts recovered the booster stage of a Falcon 9 for the first time in 2015 by landing it at Cape Canaveral, Florida. And as of this writing, per the company’s website, SpaceX has launched 148 Falcon 9s, and 88 of those were with previously flown boosters. This accomplishment set SpaceX above its competition for reusable launch vehicles and put it into a favorable position for the development of the Starship.

The Falcon feat was indeed a groundbreaking accomplishment that demonstrated a near order-of-magnitude cost savings for payload insertion into low-Earth orbit. SpaceX has estimated a Falcon 9 launch cost of $2,700 per kilogram versus $20,000 per kilogram if launched by conventional means. And those costs should continue to go down as more companies adopt reusability and competition increases.

The Falcon 9 achievement isn’t just about dollars saved today. Now that we know that spent stages can land on drone barges or fly back to the launch site, this opens the door to creative new architectures. For instance, a two-stage winged rocket plane could operate from a conventional airport, as we suggested last May in this magazine. Each winged stage would fly back to its airport of origin to be reassembled, refueled and reused. This scenario would both simplify operations and make permanent a revolutionary favorable bend in the space access cost curve.

In the words of Konstantin Tsiolkovsky, the father of theoretical and applied astronautics, “The Earth is the cradle of humanity, but one cannot live in the cradle forever.” Humans are destined for the cosmos, and we will find a way.

Philip I. Moynihan retired in 2007 after 45 years as an aerospace engineer, first at Rocketdyne in California and later at the NASA-funded Jet Propulsion Laboratory. He holds a doctorate in mechanical engineering from the University of Southern California.

Eugene A. Ustinov retired in 2021 after 50 years as a remote sensing scientist at the Space Research Institute and Institute of Atmospheric Physics in Russia, then at NASA’s Goddard Space Flight Center in Maryland and later at the NASA-funded Jet Propulsion Laboratory in California. He holds a doctorate from the Space Research Institute in Russia and a doctorate from Tartu University in Estonia, both in the area of theory of radiative transfer and application to remote sensing.