Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

Expanding civilization off Earth will require incredible breakthroughs. Resources must be mined on site and turned into fuel, drinking water and other supplies for settlers, who can’t carry adequate food and health care infrastructure with them. The transportation challenges will be enormous. Also, linking future settlers to each other and Earth will require high-throughput communications that today do not exist in deep space.

Debra Werner and Cat Hofacker sought out an entrepreneur in each of these areas to point the way toward solutions.

Communications

Mina Mitry Co-founder and CEO of Kepler

Communications in Toronto

We’ve never built telecommunications infrastructure to support predominantly connectivity outside of the Earth, apart from the TDRSS [Tracking and Data Relay Satellite System] and EDRSS [European Data Relay Satellite System], which are government-led initiatives.

TDRSS is difficult to access and exorbitant in costs for any commercial user. EDRSS carries similar challenges. Even the EDRSS laser communications terminal is difficult to support on many missions because it consumes gross amounts of power and it’s difficult to point. That’s not conducive to the early markets that will adopt in-space connectivity.

So, one of the biggest challenges will be providing communications devices and infrastructures that are compatible with the small, low-cost machine architecture of many early users of in-space connectivity. I started Kepler Communications with three other engineers in 2015 to create a commercial replacement for TDRSS.

The path toward supporting off-world civilization begins with supporting these early users of in-space connectivity. Incremental markets formed using services in space will be the reason we’re able to get off-world. At Kepler, we’re looking at concepts for lunar communications because of all the lunar initiatives taking place. If the concepts are for data-relay communications, then each bit or byte would travel from a point on the lunar surface through a few satellites to reach Earth.

Historically, most communications concepts have been led by the Deep Space Network or direct-to-Earth connectivity. The high data consumption that will inevitably come from more prevalent use of space will call for within-space networking to support the vast variety of user requirements.

The biggest challenge for lunar communications will be the radiation environment. It’s encouraging that the MarCO satellites that relayed imagery from NASA’s InSight lander in 2018 demonstrated the capabilities you can get from lower-cost small satellites.

Lunar satellites will need more radiation hardening for hardware and software. One of the biggest issues related to radios in orbit is single-event upset of a logic gate. That happens when a high dose of ionizing radiation turns a zero into a one inside a software-defined radio’s signal processor, which deciphers the waveform. We would program the satellites to vote on which circuit has the right solution. That would allow us to overcome some of these radiation issues. It’s like having three people vote on the right solution. If one is a little delusional, two out of three can agree on the answer.

Food production

Robert Richter

Director of environmental systems at Sierra Nevada Corp. in Colorado

Having enough food on board will be one of the biggest obstacles to sustaining people off the planet for long periods of time. Frequent resupply trips won’t be feasible when crews are a two-year journey away on Mars. Being able to grow fresh produce onboard not only frees up valuable space and mass, but plants provide micronutrients that a lot of the dehydrated foods that make up the bulk of astronauts’ diets lose over time as they sit on a shelf. We’re also finding out in talking to a lot of these astronauts that there are psychological benefits. It’s something green that reminds them of home.

The lack of gravity provides the biggest challenge to in-space food production. It’s this balancing point of providing the right amount and mixture of water and nutrient solution to the roots to really get each plant to thrive. In 2012, the former company Orbitec, now fully integrated as SNC, designed the Vegetable Production System, or Veggie, as a simple way to achieve this. Each unit consists of a rectangular tray set into a plastic bellows that creates a microclimate within itself by keeping the roots and the shoots at a similar temperature. A Veggie can hold approximately six plants, which are contained in little fabric pillows full of a clay media. Unlike a loose soil, the clay acts as a rigid sponge, allowing the plant roots to extract water through small openings without providing so much water that they drown. The plants also draw energy from a combination of overhead red, green and blue LED lights; the red and blue parts of the spectrum are what the plants absorb.

There are currently two Veggie units on ISS growing small amounts of produce. The next step is large-scale food production, for which you need to optimize the number of plants grown in what space is available to you. SNC’s answer to this is the Astro Garden. Each rectangular unit consists of eight independent chambers, and units can be stacked on top of each other against the side of a spacecraft wall, such as the inflatable LIFE Habitat SNC is building.

If I were to forecast, I would say the next stepping stone is more plant-based proteins that simulate meat. And if you reach massive scales of production, some of these plants could eventually serve as a hybrid life support system by providing supplemental oxygen. As we go to Mars, you’re going to see the evolution of technologies that are required for self-sustaining settlements.

Manufacturing

John Vellinger

President and CEO of Techshot in Indiana

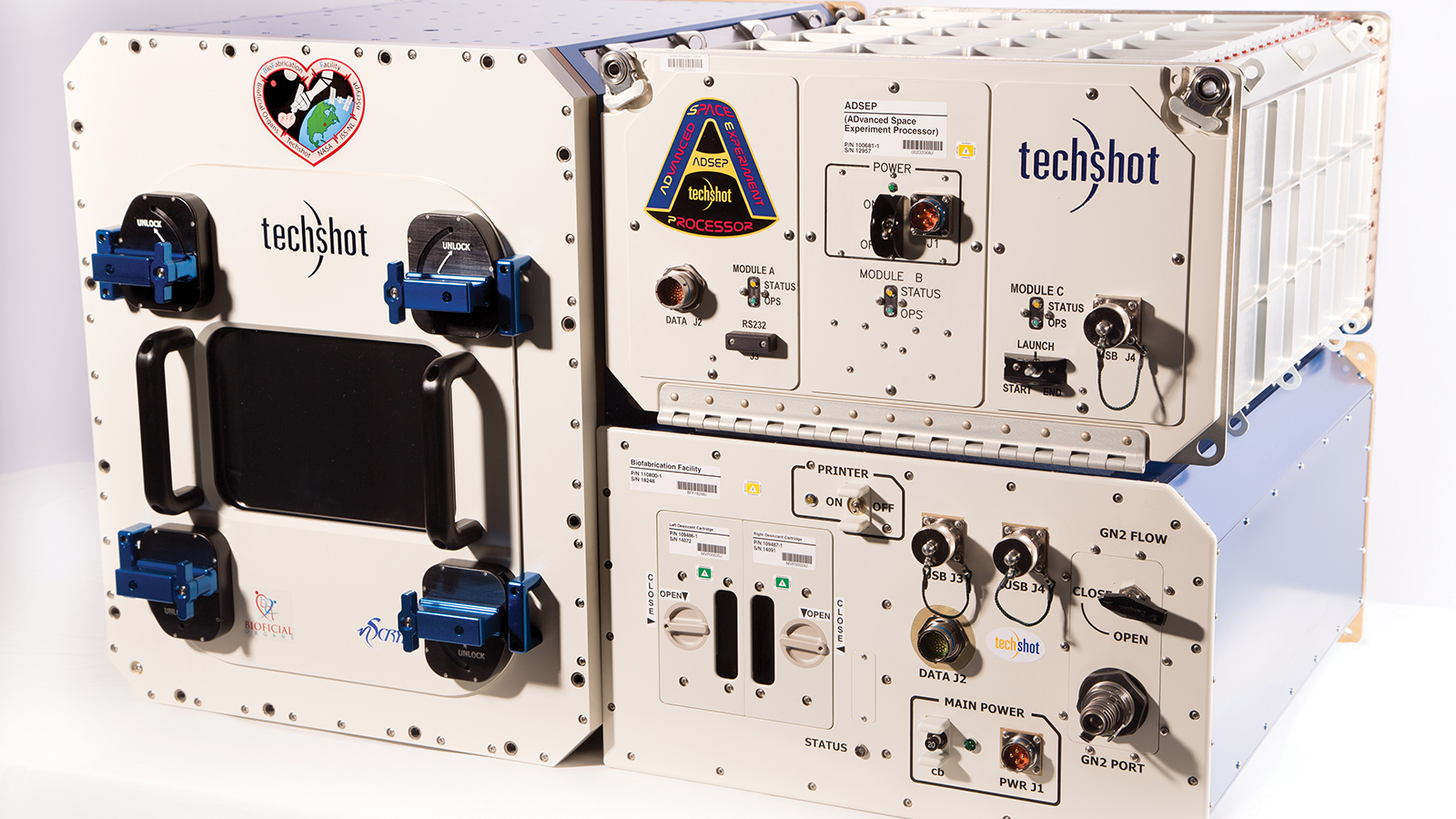

One of the exciting opportunities for Techshot is biomanufacturing in space. We have bioprinted human heart cells and a meniscus in our 3D BioFabrication Facility or BFF, located aboard the International Space Station inside the U.S. National Laboratory.

Our near-term objectives are manufacturing tissue and biopharmaceuticals for people on Earth. In the long term, this technology could help doctors repair tissue damaged in space by radiation.

Whether it’s an astronaut on an exploration mission in the next 10 years, or a citizen of a distant off-world civilization, each will be at risk of suffering severe radiation damage. One of our goals is to develop technology to print replacement adenoid and lymphoid immune tissue.

We would collect a space traveler’s cells prior to launch (or perhaps at birth for someone born in space) to store in radiation-resistant enclosures. The Techshot Cell Factory would multiply the cells and produce the inks for 3D bioprinting in BFF.

For now, our biggest challenge is getting tissues and the cells up to the space station and back down. Thermal control is very important to living tissues. That means we need power to maintain thermal conditions for living tissues while they are being transported. There are only so many of those powered lockers available.

As commercial space stations come online, I think that’s going to ease some of these constraints. We are working with Axiom, the company NASA selected to attach a commercial module to the space station in 2024, and other commercial space station builders to find room for more bioprinters and other microgravity research equipment. Everybody realizes this is a new era and a new opportunity.

We are working on a Multimaterial Fabrication Laboratory called FabLab, a 3D printer for plastic, metal, ceramics and electronics. Metal and electronics manufacturing is a critical technology for long-term exploration missions. The philosophy is: Make it; don’t take it.

The challenge is having the right raw materials to make the most diverse set of electronic components. You obviously can’t make everything. You have to select the raw materials you think are most likely to be utilized on an exploration mission. With the current FabLab prototype, we’re back to the same issue: space constraints. We need room to test this stuff on board the space station.

Mining

Daniel Faber

Co-founder and CEO of Orbit Fab in California; former CEO of Deep Space Industries in California

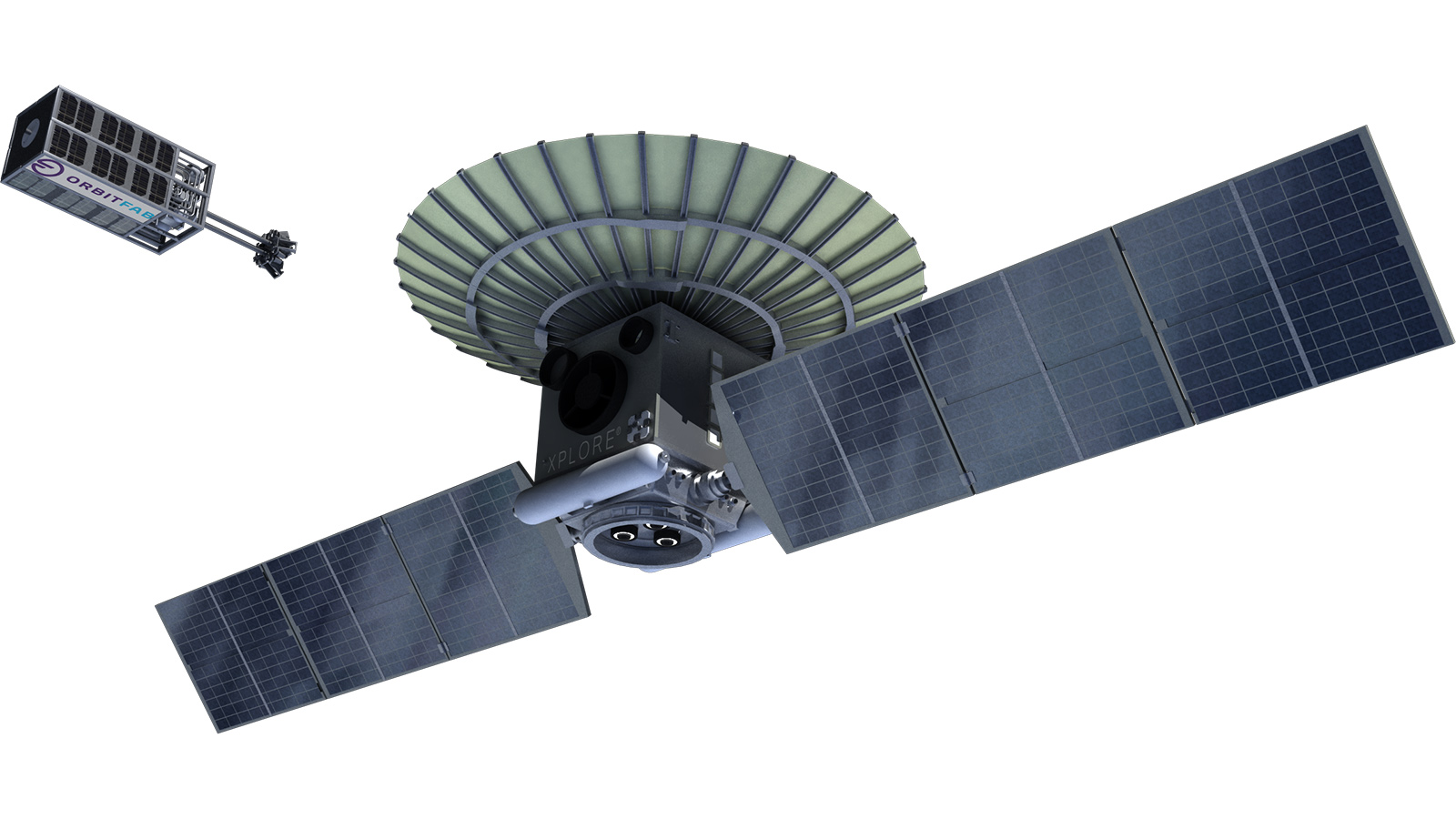

The biggest challenge to building an off-planet resource economy is demand. Nobody is buying water and other space resources at the moment partly because nobody is selling them. I founded Orbit Fab two years ago with Jeremy Schiel to build gas stations in space to refuel satellites and extend their lives. We could see a demand for propellant in orbit. Initially, we will address the demand with propellant we lift off the Earth. We will create that supply chain. Then, if somebody can get propellant to us even a fraction cheaper by bringing it from an asteroid or the moon, we’ll take that propellant and distribute it.

Earlier, at Deep Space Industries, we saw asteroids as the most promising prospective target for mining metals for off-world manufacturing and habitat construction and also for sale on Earth. We conducted a desktop scoping study of a mining operation for asteroids including extraction, processing, manufacturing and transportation. In terms of challenges, assessing diggability is the toughest. We can’t get that from meteorite samples because the only samples we have are the ones that survived fiery passages through Earth’s atmosphere. We don’t know what the rocks are like in space and we don’t have local verification to confirm the mineralogy. Every time we touch another planetary body or comet or asteroid, we learn something about the variability of those surfaces.

Six years ago, when the European Space Agency dispatched its Philae lander to close in on comet 67P at 3.6 kph, no one knew for certain what kind of surface it would encounter. The surface could have been sticky or solid rock or so fluffy the lander would disappear. What happened was the lander bounced and then the surface shattered and a crater opened up underneath. It was a creme brulee-type surface.

We may learn that black asteroids have specific properties and shinier ones have other properties. We need those correlations to know which rocks are easy to extract. We know that for mining operations on Earth, but even then we have to run pilot programs to make sure extraction processes work properly.

Transportation

Joel Sercel

Founder and CEO of Trans Astronautica Corp. in California

The biggest challenge to building an off-world future with hundreds, thousands and then millions of people living and working in space will be learning to harvest and use extraterrestrial resources to supply fully reusable spaceships. Humanity is on the verge of having reusable rockets that can carry large numbers of people to space affordably. But it will never be affordable for us to bring up all the rocket propellant, air and water that we will need for those people to live and work in space in a sustainable way. For that, we need to learn to harvest and use the resources of the moon and asteroids. Both SpaceX and Blue Origin are making great progress toward affordable, reusable rockets and spacecraft, but what they are doing is not enough.

I formed TransAstra several years ago to do the fundamental research and develop the technology to harvest water, methane and other resources from asteroids and lunar polar ices. The reusable vehicles that SpaceX and Blue Origin are developing will need rocket propellant and other consumables. TransAstra will supply them. The science is clear that many near-Earth asteroids are rich with the ingredients in rocket propellant: carbon, methane and water. The lunar poles are full of water ice and other valuable materials. TransAstra is developing the technologies and the systems to harvest those ices so they can be made into rocket propellant and sold in space to supply NASA, government and private spaceships. Mars is also known to have water, and the Martian atmosphere is primarily composed of carbon dioxide. With water and carbon dioxide, we can make liquid oxygen, liquid hydrogen and methane, the propellants SpaceX and Blue Origin will need.

Once we have reusable vehicles and can harvest propellant locally, travel in space can start to become so affordable that large scientific outposts and hotels will make economic sense on the moon. After that, we will build towns and cities in space supplied from the asteroids. Here at TransAstra, we also plan to use water directly as propellant. We’ve invented a patent-pending solar thermal thruster called Omnivore that concentrates sunlight to turn water into superheated steam. Water propellant has key advantages in terms of logistics and ease of storage. But we can’t use water directly as propellant to launch from planetary surfaces. The thrust isn’t high enough.

In addition to Omnivore we have also invented, tested and applied for patents on other key innovations. These include the optical mining method to harvest asteroid resources and a rover-based process that uses radiation to harvest water from lunar polar regions. Finally, we have a breakthrough power system called Sun Flower to provide megawatts of low-cost electric power to support outposts and mining operations in lunar polar regions.

“Once we have reusable vehicles and can harvest propellant locally, travel in space can start to become so affordable that large scientific outposts and hotels will make economic sense on the moon.”

Joel Sercel, Trans Astronautica Corp.

About Debra Werner

A longtime contributor to Aerospace America, Debra is also a correspondent for Space News on the West Coast of the United States.

About cat hofacker

Cat helps guide our coverage and keeps production of the print magazine on schedule. She became associate editor in 2021 after two years as our staff reporter. Cat joined us in 2019 after covering the 2018 congressional midterm elections as an intern for USA Today.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.