Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

Researchers hope to solve a deadly problem for U.S. troops

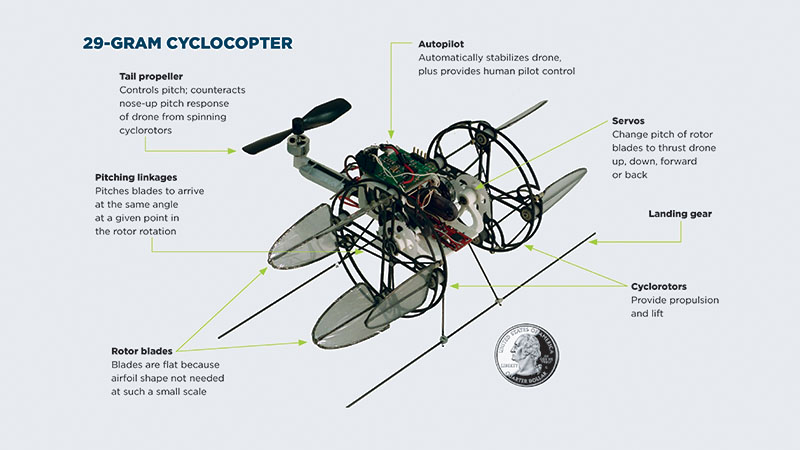

For researchers building what could be the world’s smallest cyclocopter — a drone powered by two spinning paddle- wheel-like cyclorotors — every gram counts. The edges of each of the craft’s eight rotor blades were made by hand-laying hair-thin carbon fiber strands preimpregnated with epoxy into a Teflon mold, along with a 0.7-millimeter-thick carbon rod for the center of the frame. Then they were baked in an oven at about 175 degrees Celsius. The frames were wrapped in 5-micron-thick sheets of Mylar, the thinnest available, to create surface area.

Each rotor assembly had to weigh the equivalent of five Tic Tac breath mints or 2.5 grams, with each of the four blades on a rotor accounting for just .12 gram. The total vehicle weight came in at just 29 grams.

“Coming up with this fabrication technique and making this ultralight blade, that was a huge challenge,” says Moble Benedict, a Texas A&M University assistant professor who advised two of his aerospace engineering Ph.D. students, Carl Runco and David Coleman at the Advanced Vertical Flight Laboratory, in designing and building the drone. Building super-light blades “was the only way we were going to scale this thing down.”

Benedict and his teammates at Texas A&M started flying the miniature cyclocopter in December 2015 and have continued testing the design under a U.S. Army program. Benedict and collaborators at the University of Maryland had flown larger versions weighing 800, 500, 235, 210 and 60 grams over the preceding 10 years. Knowing that cyclocopters might not be the only answer for miniature flight, Benedict and Coleman also began flying a 62-gram flapping drone, dubbed the Robotic Hummingbird, for the Army in 2015.

They want to find the best solution to a deadly problem soldiers faced in Afghanistan, and one that’s likely to come up in other locations where urban canyons and forest canopies play the role of mountains. Soldiers in Afghanistan would get pinned down in a valley with limited knowledge of what might lie over the next ridge and with only a tenuous communications link to commanders. By pulling a cyclocopter or a flapping drone from a rucksack and letting it fly from the palm of his or her hand, a soldier of the future would gain a bird’s eye view with the aid of a 1- or 2-gram camera or the ability to relay communications via a network of other drones.

For aircraft technologists, questions abound, from which drone concept would work best in which circumstances to how cyclocopters and flapping drones would perform compared to conventional quadcopters and miniature helicopters, especially when faced with the great bane of all micro air vehicles: wind gusts.

The U.S. Army hopes to answer those questions under a program called MAST, short for Micro Autonomous Systems and Technology, which is based at the Army Research Laboratory in Adelphi, Maryland, and is set to wind down this year. MAST pays universities and companies to develop miniature ground and flying robots that could pay off in 10 to 30 years for soldiers in the field. Concepts funded under MAST include navigation sensors and joint robotic mapping schemes, perching mechanics and adhesives, alternative energy sources for micro vehicles, quadcopters, ducted-rotor aircraft, fixed-wing aircraft with wings that can lengthen or shrink, bee-sized flapping fliers and also Benedict’s cyclocopter and flapping-wing aircraft. The main purpose of MAST is to identify particular modes of propulsion worthy of further research, but the Army is also curious about the comparisons among the craft.

“Can these alternative configurations be more efficient; can they be more agile? You can start to ask questions like: ‘Is it useful to me to have it flapping because it looks like a bird; does that add some benefit?’” says Chris Kroninger, the microsystem mechanics team leader at the Army Research Lab.

The Army program ends in September though Benedict and his team plan to continue their research on micro aircraft.

Beating the wind

The cyclocopter produces lift and horizontal movement from the spinning cyclorotors, each with four blades that tilt to 45 degrees of lift at the top and bottom of their cycles (12 and 6 on the clock) and to 0 degrees at 9 and 3. The tail rotor is a traditional-looking propeller that spins facing up to control pitch.

The flapping-wing drone has two nearly rectangular but slightly pointed wings that flap 22 times per second, controlling its hover and horizontal movements. The wings are translucent.

Testing of the flapping and cyclocopter designs will culminate in August 2017, likely at the Army Research Laboratory in Maryland with the micro drones demonstrating hovering, flying forward and performing basic maneuvers. The researchers are also testing how fast the drones can fly, how quickly they can maneuver and how they fly when hit by simulated wind gusts from a fan, Benedict says.

Because of the obstacles that tiny drones encounter, they are likely to be always moving and adjusting their flight, so they must be agile, Kroninger says.

“We’re interested in getting down in the urban canyon; we’re interested in moving under the canopy; the sorts of places where soldiers operate. In those spaces, you’ve got gusts and wind disturbances that are on length scales that are the size of the vehicles,” he says, plus the tiny aircraft have to adjust to the change in aerodynamic forces that occur close to the ground.“Also, there’s an equivalent wall effect: If you get too close to a tree, it will pull you in. So you need an aircraft that’s intrinsically agile, and you’re not going to do much steady flight at these small scales.”

Wind gusts are tricky for miniature unmanned aircraft, because as the size of an aircraft is scaled down, its aerodynamic force will drop by the size decrease squared, while its inertia will drop by the size decrease to the fifth power, Benedict says. That’s why a manned helicopter is fine flying through 10- to 15-meter-per-second wind gusts, while a toy helicopter can’t fly through 2-meter-per-second gusts.

Insects and hummingbirds can maneuver through wind gusts, and their flapping-wing flight dynamics may hold the key to why that is possible, Benedict says.

Traditional spinning helicopter rotors can be more efficient than flapping wings, producing steady air flows, but they can also fail to produce lift when that air flow is interrupted by a wind gust, he explains. The hummingbird’s flapping wings produce an extremely unsteady flow field, and they’re better able to create lift even when hit by a gust. Each wing creates a leading-edge vortex, or a small whirlwind sitting on top of the wing, which is an area of extreme low pressure that enhances lift. The bird, and flapping-wing insects, can keep these vortices stable on the wing.

Hummingbirds — at the end of their wing stroke — can time their wing rotation to produce either an upward or downward force and can reverse the pitch of their wing to produce upward thrust on both the downstroke and upstroke, Benedict says. The birds’ wings can also capture energy from the wake of a previous wing stroke, and hummingbirds can actively control their pitch, roll and yaw, and make adjustments based on their sensing the wind or the flow field on their wings.

Flight control

Flapping-wing drones are worth studying because of their agility and wind gust tolerance, though not for efficiency, Benedict says. The flapping-wing drone controls its flight path and its hover like a hummingbird would: by changing the length of one wing’s stroke relative to the other wing to control roll, by tilting forward both planes of flapping to change pitch, and by tilting one wing’s plane forward and the other plane back to change yaw.

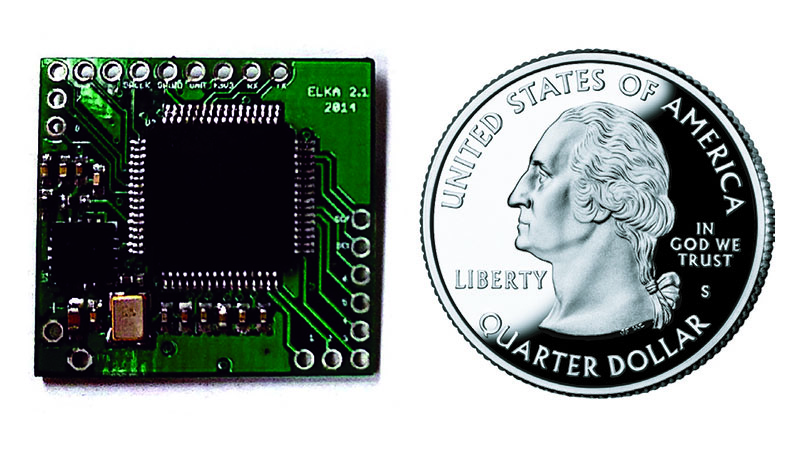

One challenge with both cyclocopters and flapping-wing aircraft is their inherent instability. The blades on a cyclorotor are always changing angles, so the aerodynamics are unsteady and changing over time. A 1.3-gram autopilot, designed at the University of Maryland by Vikram Hrishikeshavan and Inderjit Chopra, controls both the 29-gram cyclocopter and the 62-gram robotic hummingbird with a microprocessor connected to a triaxial gyroscope and tri-axial accelerometer. With both drones the microprocessor takes the raw data from the gyro and accelerometer and directs the aircrafts’ controllers — motors and servos — to automatically stabilize them. The autopilot also allows the drones to send and receive data wirelessly, and for the human pilot to provide higher-level commands, on top of the automatic stabilization. But without the stabilization, a human pilot won’t be able to fly these vehicles, Benedict says.

The flapping-wing drone was particularly difficult to design and fly because even slight changes to the design affected its response to controls significantly, Benedict says.

The intrinsic instability of the cyclocopter and flapping-wing concepts can actually be an advantage, because designers have developed such a fast-responding control system to handle them, Kroninger says. “So in certain domains, you can quickly move actuators and therefore achieve some level of high control authority.”

Cyclocopters, compared to traditional helicopters and quadcopters, are more agile because they can use thrust vectoring — changing the pitch of the rotor blades as the blades rotate through a 360-degree cycle — to directly push the aircraft in any of those 360 degrees, Benedict says. Cyclocopters are also more aerodynamically efficient, with the aircraft producing more thrust per unit of power. Traditional helicopters and quadcopters tilt forward to fly forward, so their advance ratio — the forward speed divided by the fixed speed of the rotor — is typically less than 0.3, while cyclocopters can achieve an advance ratio of 1, so they have the potential to fly faster than the helicopter and quadcopter.

Moving by thrust vectoring instead of tilting also keeps the cyclocopter at a level attitude, which could be an advantage for sensors it might carry, Benedict says. And the entire blade of a cyclorotor produces thrust, compared to just the tips of the rotors on traditional helicopters and quadcopters, which means that cyclocopters can achieve the same thrust at a lower RPM and potentially operate with less noise than traditional helicopters and quadcopters.

Weight control

The biggest disadvantage of the cyclocopter compared to traditional helicopters and quadcopters is that the rotors are heavier, which drives up the weight of the empty cyclocopter, Benedict says. But considering that helicopter technology is so much more advanced than the little-studied cyclocopter concept, he thinks more research will close the gap.

“I still think there’s a lot of room for improvement with the cyclocopter to drive down the weight,” he explains. “We have an 80- to 90-year history on helicopters — I feel it’s kind of unfair to compare the technology, which is so mature. The cyclorotor is still in the early stages.”

Benedict and his teammates were able to reduce the weight and increase the strength of the cyclocopter rotors by building the blades out of newer composite materials, dropping an airfoil shape for the blades in favor of a flat insect-wing-like design and anchoring the blades on just one end instead of both. The lower blade weight allowed for a lighter hub and arms in the rotor, which were very heavy in earlier cyclocopter designs to withstand the spinning forces. The team also performed extensive tests to determine the best blade design for maximum thrust and efficiency at the lowest RPM possible, because the faster the cyclorotor spun, the greater the centripetal force and its bending effect on the blades.

“It’s not something you can just design without proper scientific understanding,” Benedict says. “You need to know how the blade pitching kinematics affect your forces; how does it affect your efficiency.”★

Scaling up tiny designs

Suspecting that smaller might not always be better when it comes to drones, researchers at Texas A&M University are also starting to study the merits of scaling up flapping-wing and cyclocopter concepts for larger unmanned aircraft for a program sponsored by the Army, Navy and NASA at the Vertical Lift Research Center of Excellence at the University of Maryland. The Texas A&M contract with the sponsors runs into 2021.

On the cyclocopter side, they will build and test larger drones to see how they perform as they scale up, how they compare to conventional helicopters, if they become any more efficient and if they can improve their rotor weight to total vehicle weight ratio. Moble Benedict, a Texas A&M assistant professor, says he believes cyclocopters could even be viable as small manned aircraft.

For the flapping-wing research, Benedict and his team will build a single 10- to 15-gram flapping wing in about six months — not the whole aircraft — to project how a 1.6-kilogram hovering drone might fare, and to see what the key barriers would be to scaling up a hover-capable flapping drone. For Benedict, the key question is: Why in nature can only insects and small birds hover, and not the larger birds? If it’s just a muscle scaling issue, then prospects for larger flapping-wing drones would be bright because the researchers

could easily scale up motors.

Among hummingbirds, the best fliers weigh about 3 grams. Hummingbirds as large as 20 grams do exist, but they are lousy fliers, Benedict says.

“This is to understand why even nature finds it difficult to find a solution at larger scales,” he says. “Hovering is something that every bird would like to do. Even an eagle would like to hover at one point.”

“We’re interested in getting down in the urban canyon; we’re interested in moving under the canopy; the sorts of places where soldiers operate. In those spaces, you’ve got gusts and wind disturbances that are on length scales that are the size of the vehicles.”

Chris Kroninger, microsystem mechanics team leader at the Army Research Lab

About Keith Button

Keith has written for C4ISR Journal and Hedge Fund Alert, where he broke news of the 2007 Bear Stearns hedge fund blowup that kicked off the global credit crisis. He is based in New York.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.