Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

Some of the most creative entrepreneurs and researchers can’t afford to buy an entire rocket to deliver their wares precisely into their preferred orbits. Often, they must compromise or expend fuel maneuvering their spacecraft after launch. Matteo Bartolini of D-Orbit describes the challenges his company faced to develop a line of satellite transporters that could be the answer.

Over the last decade, space has been colonized by nontraditional players working to make spaceflight and commercial space activities more cost-effective, accessible and reliable. The company where I work, D-Orbit, based in Como, Italy, is one of these companies.

The first mission at our founding in 2011 was to sweep debris from space. We still do that, but in the ensuing years we have recognized additional needs.

Most importantly, in 2016 we realized that some of those planning to launch experimental satellites or constellations of satellites had frustratingly little choice over the orbits for their spacecraft. For reasons of cost and performance, these customers were often relegated to sharing rides on rockets together with other satellites. In such a ride-share arrangement, the satellites are released almost simultaneously in the same orbit that was chosen by the launch provider based on the orbit’s popularity and likelihood of bringing in the most customers. On a ride-share, one must either be satisfied with the slot where the launch vehicle released you or take on the burden of maneuvering to a preferred operational slot.

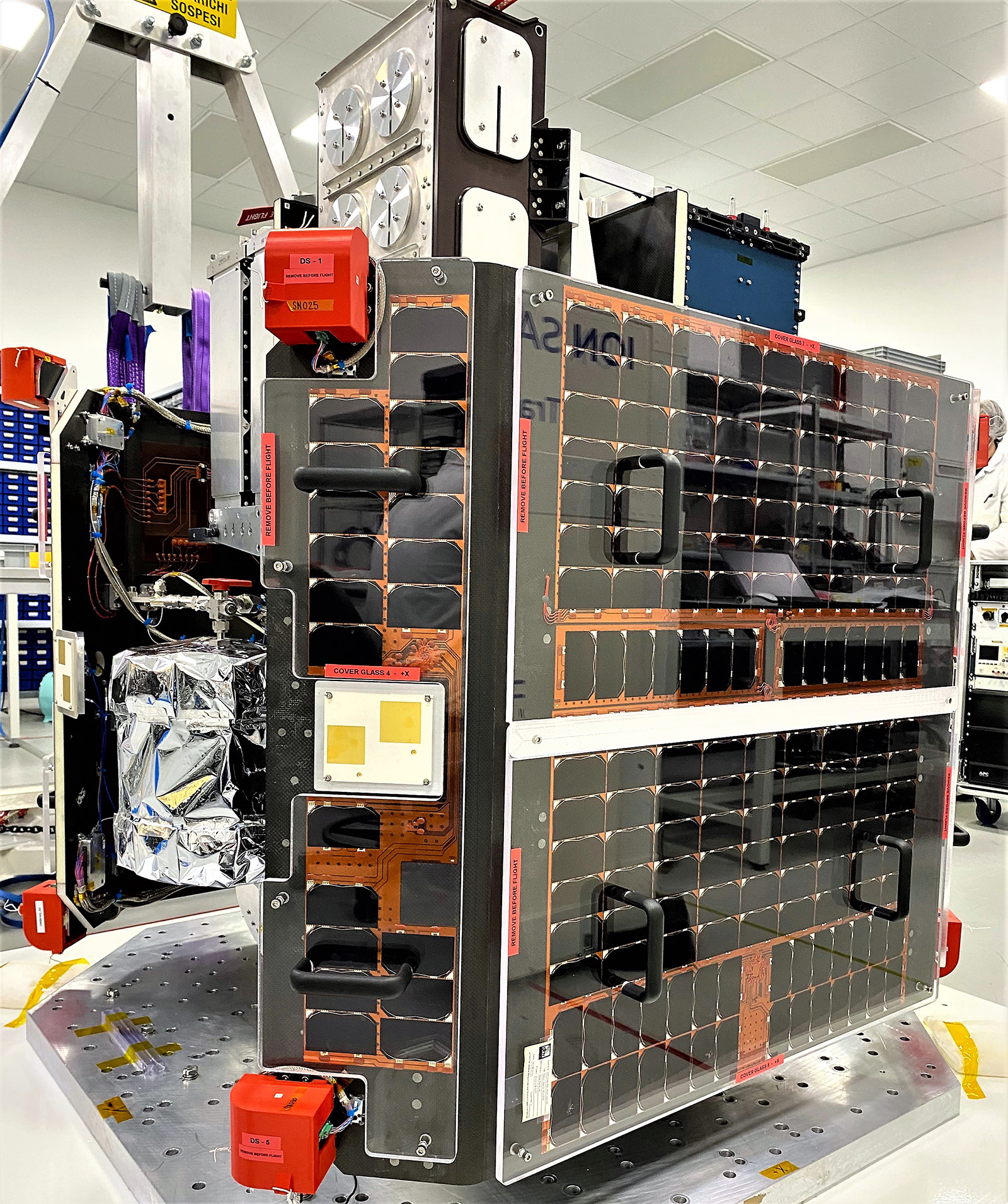

So, D-Orbit began drawing up plans to create a fleet of orbital transfer vehicles, or OTVs, capable of releasing multiple payloads into precise orbits. It turns out these OTVs, each an aluminum and composite cube-shaped dispenser roughly the size of an industrial washing machine, can also host cloud computing devices, cameras and other equipment. Today, we call these spacecraft ION Satellite Carriers, ION being short for “In Orbit Now.” So far, we have launched six of them as commercial missions, most recently on May 25 aboard SpaceX’s Transporter-5 ride-share mission.

Given our belief in protecting the space environment, we have a plan for deorbiting each carrier, and we help our customers be compliant with space debris regulations.

Our customers have the ability to choose the best orbit for their unique commercial or scientific needs. If conventional launchers can be thought of as the equivalent of ocean-going vessels transporting freight containers to a seaport, our ION Satellite Carriers are the delivery trucks that set off from that port to drop packages at each customer’s door, a true “last-mile” delivery service in orbit.

We calculated that our ION Satellite Carriers reduce the time it takes to completely deploy a satellite constellation by 85% while reducing the launch costs of the entire constellation by up to 40%.

Early work

To achieve the required maneuverability, our engineers use a green, bipropellant propulsion system whose six nozzles maneuver the spacecraft to adjust orbital parameters including altitude, inclination relative to Earth’s equator and swivel, also called the right ascension of the ascending node, or RAAN. They also devised a technique for adjusting the attitude of each carrier with reaction wheels. Now, from our mission command center in Italy, or in some cases even from someone’s home office via cloud computing, we can program a carrier to maneuver to a new orbit and release one satellite in one direction and then adjust the attitude and release another satellite in an entirely different direction.

These technologies are the first of their kind, our knowledge of the industry shows. We have gone through several tests, both on the ground and on orbit, to improve our ability to perform orbital maneuvers and our mission control software. Every time we successfully test in orbit a performance improvement or a new capability of our carrier, it is a very emotional moment, filled with pride and satisfaction. Over the six missions we have launched so far, the team performed a multitude of complex orbital maneuvers with our carriers during different phases of the missions. We’ve demonstrated changing altitude and inclination, achieved true anomaly phasing and performed RAAN shifts. The first time we perform a new maneuver, we do much of the commanding manually, and on the following missions, the same maneuvers are performed in a more automatic and independent manner. Mastering new orbital maneuvers and capabilities during nearly every mission represents a fundamental milestone for us; to be as competitive as possible, we strive to increase the level of complexity, as needed, with each new mission.

In our first orbital mission, we were able to validate our precise deployment strategy, which is based on a combination of direction deployment and ejection force. This creates a wide separation between deploying spacecraft, so our customers can acquire the signal faster while ensuring a stable, collision-free formation. A triple fault-tolerant mechanism guarantees the release of all satellites before the end of the mission, even in case of malfunction.

Another important aspect of our missions is that we give customers the opportunity to test their technology in orbit. For customers performing space experiments, we recognized that a plug-and-play approach was needed. As a result, we created a mechanical, electrical and data interface that enables a faster integration of experiments and instruments onboard — while allowing mission controllers to operate them as subsystems of ION.

In order to do this, though, each ION Satellite Carrier needed to be able to provide power over different voltage values to one or more experiments simultaneously. The D-Orbit team had to think of an intermediate support structure that was easy to attach a carrier to on one side but could also allocate experiments of different volumes and sizes (from tiny electronic boards to optical elements) on the other side.

The data interface was also very difficult to figure out because a customer’s test payload must work over different interfaces and protocols. Our engineering team had the challenge of designing and building an interface board capable of connecting all the possible interfaces the experiment could have with the ION Flight Computer.

In an example of our flexibility, a prospective customer informed us it could not afford to build and launch a free-flying satellite to test a new camera, so our engineers installed the camera into a tubular structure that was then integrated onto our carrier. Our flight operations team then operated the camera to test it for the customer.

Launching a multinational “Wild Ride”

A groundbreaking and unique mission for us because of its scope has been our third one, the ongoing Wild Ride, in which a Falcon 9 rocket in June 2021 launched an ION Satellite Carrier containing six satellites and 12 hosted payloads for clients from 14 different countries, including Bulgaria, Finland, Kuwait, the Netherlands, Spain and the United States. After releasing the satellites, we tested a miniature low-power, high-performance laser communication terminal specifically designed for small satellites. A subsequent phase of that mission has been the first test of our D-Orbit Cloud Platform, an on-orbit cloud computing and data storage service utilizing a radiation tolerant computing module by Unibap, an artificial intelligence company based in Sweden. This first test campaign executed 23 separate SpaceCloud-compatible applications from a variety of partners. A hypothetical customer could, for instance, feed images of Earth to the D-Orbit Cloud Platform, where AI software would rifle through them to detect an oil spill or a lost ship and send only the relevant images back to the ground, thus saving an enormous amount of downlink bandwidth and cost.

Every mission we launch, including Wild Ride, is also managed with Aurora, our cloud-based mission control software suite. Aurora aims to enable satellite operators to manage and control multiple payloads simultaneously from any location in the world, eliminating the high costs connected with software design, development, testing, deployment and maintenance.

The future of the new space economy

D-Orbit is also working on projects that do not involve space transportation. For example, we are in the process of attaching a synthetic aperture radar on the ION platform. Our goal is to show that ION is not only a good family of services for orbital transportation but can also serve as a valuable stand-alone platform. In the future, we hope to make ION available to more customers with the goal that they can install their own sensor in the satellite.

While we recognize the commercial space industry is still in its earliest years, we expect exponential growth and more innovation on the horizon. One of the key goals at D-Orbit is to make space available for customers with an approach that’s even easier, moving it from a challenge to a service. By using some of the most cutting-edge technology and working together as a team, we can confront the challenges currently facing space sustainability and logistics and make it a truly exceptional field.

Matteo Bartolini

is head of sales engineering for D-Orbit, based near Como, Italy. He has a bachelor’s degree in aerospace engineering and master’s degrees in aeronautical engineering and civil aviation management, all from from Sapienza University of Rome.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.