Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

For decades, it seemed like the only way to deliver detailed pictures of Earth from space was to orbit large telescopes and point them back at us. Today, companies are upending this conventional wisdom. Debra Werner looks at how one company, BlackSky, aims to storm the commercial imagery market.

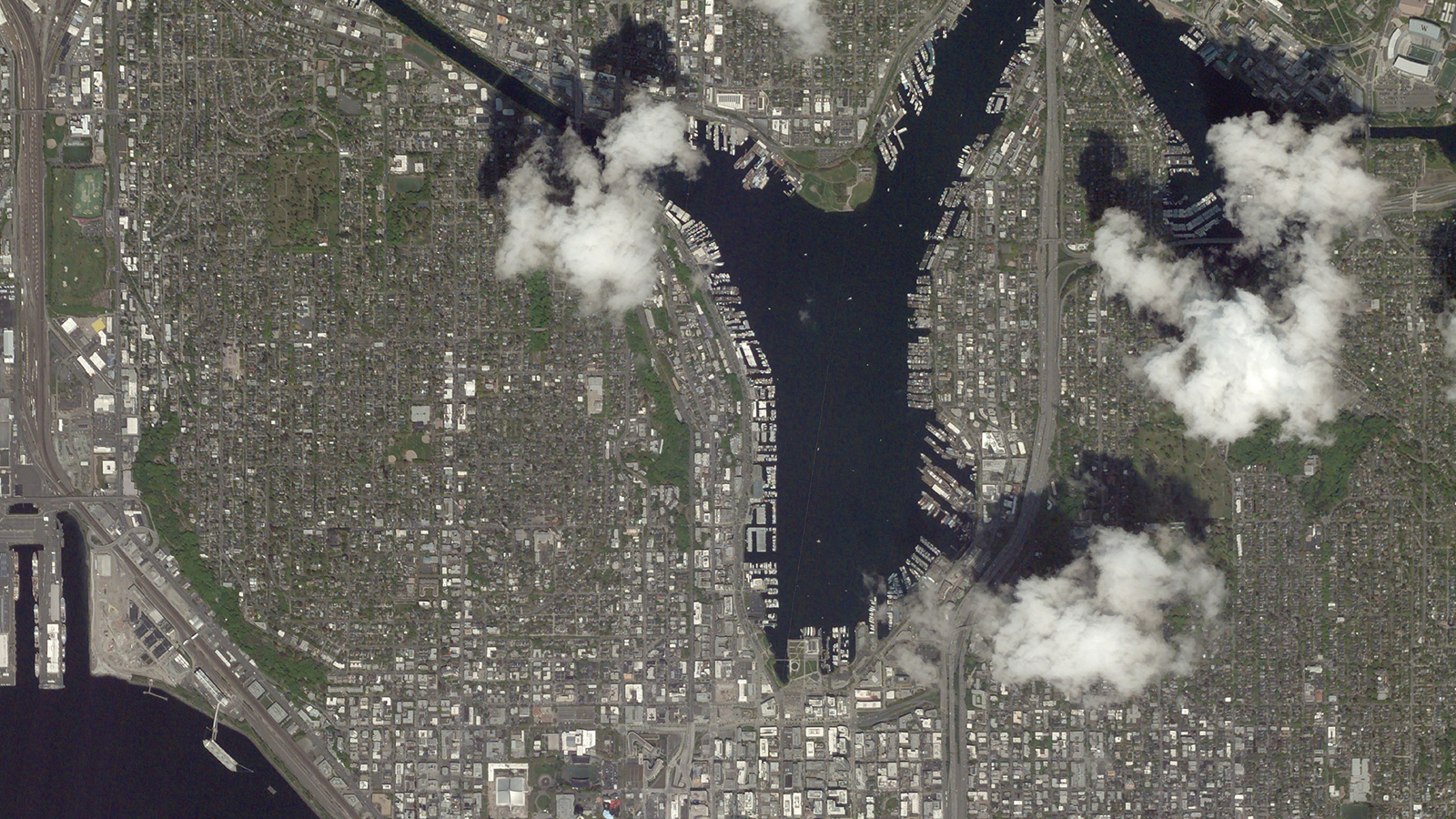

Ikonos, the first commercial satellite to image Earth in submeter resolution, was about the size of two luxury refrigerators, whereas the Global satellites flown by BlackSky are the size of a dorm-room fridge.

Yet images from Ikonos and these newer satellites are of comparable resolution, 82 centimeters in the case of Ikonos and 1 meter for the Global satellites. The images are sharp enough to detect changes in the terrain and the details of human-made structures and vehicles. Before Ikonos reached orbit in 1999, this resolution was strictly the purview of government spy satellites.

How is it possible that a Global satellite a fraction of the size of Ikonos can deliver images of about the same resolution and on top of that in color rather than black and white? BlackSky, the subsidiary of Seattle launch broker Spaceflight Industries, won’t say exactly for fear of tipping off competitors in the hot commercial imagery market for sales to Fortune 500 companies, the U.S. National Reconnaissance Office and others.

But engineers involved with the project agreed to discuss the broad outlines of their strategy, which centered on tying together a host of small technical improvements that would wring maximum value from the photons entering each satellite’s telescope. In areas they could not discuss, I spoke to outside experts to glean some informed speculation based on industry trends.

What’s certain is that the BlackSky strategy is starting to be put to the test. The company has begun serving customers with three Global satellites in orbit, and a fourth was poised for launch by the end of August. An initial constellation of eight satellites should be in place by the end of the year.

As for the engineering strategy, “It’s not magic. It’s just very deliberate systems engineering and technology insertion,” says Nick Merski, a systems engineer and operations vice president for Spaceflight Industries.

Specifically, engineers tied together advances in optics and detector materials to deliver a high signal-to-noise ratio and excellent modulation transfer function, a measure of an optical system’s ability to show contrast within an image. These measures are among the keys to delivering fine resolution.

The quest began with an optical challenge. Ikonos gathered photons with a 70-cm primary mirror, but the optics on the BlackSky satellites needed to be a fraction of that size. By keeping the design small, the company could take advantage of lower launch costs and miniature electronics and offer customers an inexpensive way to obtain multiple daily views of the same locations on the ground.

BlackSky chose L3 Harris Technologies Intelligence, Surveillance, and Reconnaissance, or ISR, for the job of making the telescope. Based in Rochester, New York, this is the former Eastman Kodak satellite group that built the Ikonos telescope.

As groundbreaking as Ikonos was, engineers at the ISR group were among the first to see the potential for making imaging satellites smaller and lighter. The trend started about five years ago, and there’s been an almost “exponential movement toward smaller,” says Murali Krishnan, vice president and general manager of the ISR group.

Saving weight with composites

For decades, the assumption in the Earth-imaging business had been that satellites needed to be relatively large (at least Ikonos-sized) to gather enough photons to produce fine-resolution images. The only way to improve the resolution, the thinking went, was to orbit a larger aperture telescope or fly the satellite at a lower altitude to intercept the reflected sunlight closer to the source, before the photons diffuse very much.

In reality, a host of factors determine image resolution, chief among them being how many photons reach the detector material and how sensitive those detectors are. Detectors are now 10 times more effective than they were when Ikonos was built, says imagery expert Lars Dyrud, founder of OmniEarth, a small satellite imagery company acquired in 2017 by EagleView, a Bothell, Washington, aerial imagery company.

To save weight without sacrificing performance, engineers at the ISR group decided to make the mirrors out of composite materials, although for proprietary reasons they won’t say how they manage to craft those materials into mirrors that reflect light with the required fidelity. The strategy reduced the weight and volume of the mirrors and shortened the production time.

L3 Harris declines to say whether it employed its patented processes for additively manufacturing mirrors by depositing successive layers of lightweight, elastic substances that resist thermal expansion. The materials include silicon carbides, carbon nanotube-filled polymeric materials and glass-ceramics. Once 3D printed, mirror cores are bonded to faceplates before the faceplates are finished with a multilayer reflective coating.

The engineers also set about shortening the length of the telescope cylinder. Again, the engineers need to avoid divulging exactly how this was done, but given trends elsewhere in the industry, they may have employed optical folding. Instead of mounting lenses at each end of a long tube, telescopes produce similarly long optical pathways by bouncing light off mirrors several times within the body of a shorter, wider telescope before it hits the detector. “You can take what would have been a 2- or 3-meter [long] telescope and scrunch it down to something like half a meter,” says Dyrud.

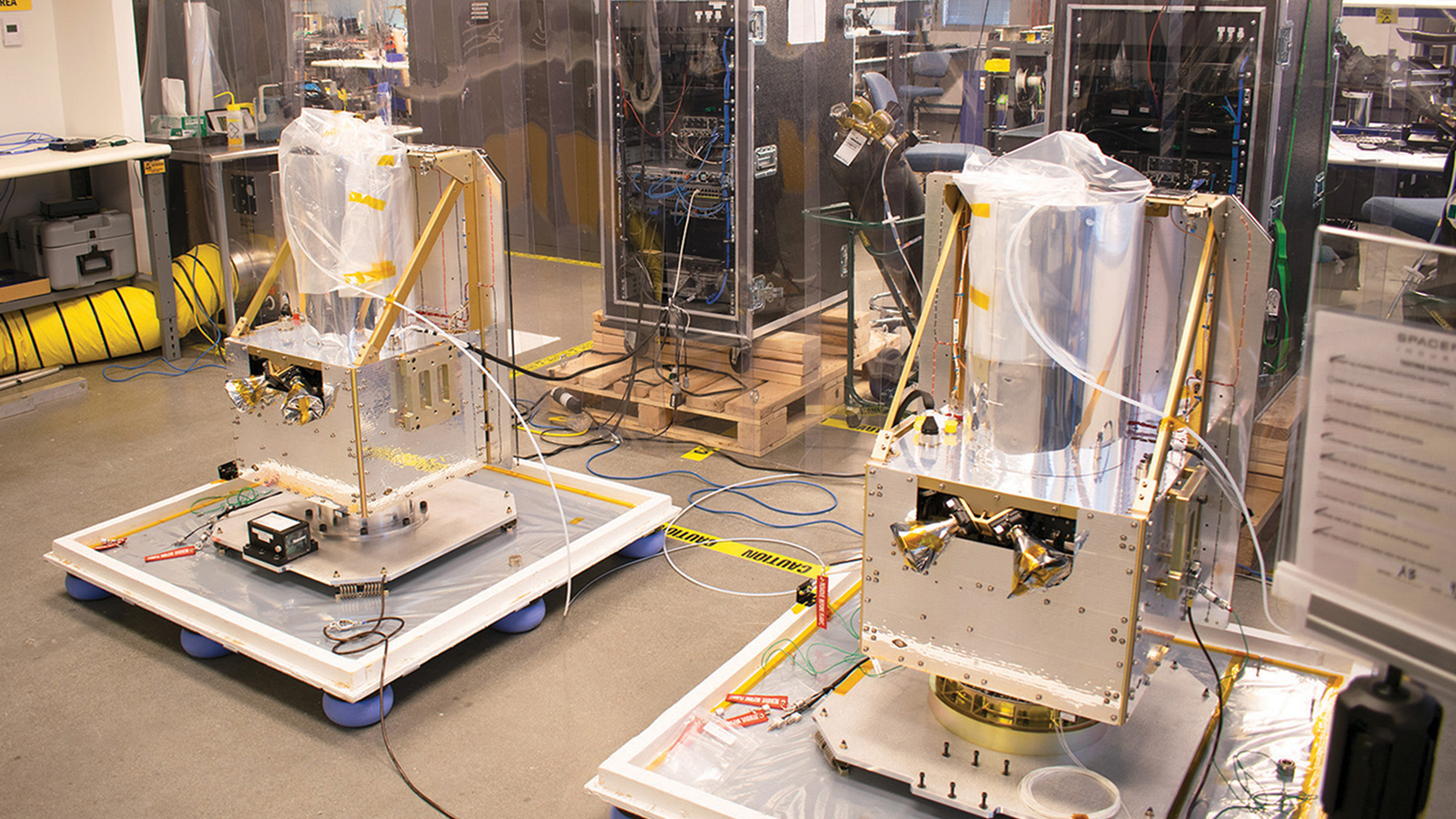

The ISR group’s technologies were put to the test in 2016, when BlackSky flew two “pathfinder satellites,” each carrying a 24-cm-diameter primary mirror inside the SpaceView 24 telescope. The new telescopes were notable for their diminutive weight of 10 kilograms, compared to 171 kg for the Ikonos telescope.

The tests went well, judging by the fact that BlackSky’s first four Global satellites, the three in orbit and one set to launch in August, are equipped with SpaceView telescopes.

Pointing the telescope

Reducing size and weight was only part of the challenge. A great telescope won’t yield high-resolution images unless it remains focused on a precise point on the ground as it zooms over at 28,000 kph.

This issue looms especially large for a small satellite, because imagers must typically be mounted directly to the spacecraft body to save mass and volume. If the satellite weighed hundreds of kilograms, it could be mounted on a platform that would isolate it from vibration. Without that possibility, the satellite itself must be steered for precise pointing, says Andrew Maurer, Honeybee Robotics engineering director. Honeybee does not work with BlackSky, but the company works with many Earth observation companies that need help pointing satellite imagers and other instruments.

BlackSky would not tell me how it addresses this pointing problem, but Maurer says there are two choices: reaction wheels or control moment gyroscopes. Reaction wheels are a simple and reliable way to fine-tune satellite pointing, but they typically can’t produce enough torque to rapidly reorient the spacecraft toward new targets. That ultimately limits the number of images a spacecraft can produce per hour, Maurer says.

Control moment gyroscopes, on the other hand, offer enough torque to rapidly turn toward new targets, but they add complexity with two sets of motors and bearings, and optical encoders. What’s more, control moment gyroscopes powerful enough for rapid repointing will struggle to produce the minuscule degree of torque required to keep a telescope pointed at its target. If the telescope drifts and then reacquires the target, the raw image comes out blurry.

In fact, “any error, be it vibrational jitter or tracking error, shows up as blur,” Maurer says. “If the tracking error is large enough, then you may miss the imaging target entirely.

“That problem is something we work a lot for imaging customers in particular,” he says.

With either approach, if the components are not balanced properly it can degrade satellite imagery.

“In these small spacecraft, you start to bump up against how well humankind can achieve that balance,” Maurer says.

That’s when processing comes in. Keep in mind these are not images captured on film, says Merski, the operations vice president at Space Industries. “They are ones and zeros that require processing to translate into pixels.”

With software techniques like computer vision, which seeks to automate human visual processing, it’s possible to work around the limitations of a particular sensor, says Scott Herman, BlackSky chief technology officer.

Processing images

BlackSky customers buy imagery for two main purposes: literal interpretation, in which terrain changes or other information is extracted through analysis, and electromagnetic radiometry, in which the precise intensities of reflected sunlight in various bands are measured. For customers seeking to measure electromagnetic radiation, “you would never manipulate the raw product,” Merski says, referring to the picture elements that form an image. “But for improving interpretability, there are image processing techniques to improve contrast and sharpness.”

Merski and Herman won’t say exactly what BlackSky does with the software for fear competitors will gain valuable insight. Patents from other Earth-imaging companies reveal some of these techniques. Companies have created algorithms to amplify specific image details and correct for variation in lighting conditions. In one common application, processors align each color image frame with higher-resolution panchromatic views of the same area. Once aligned, objects on the ground like ships or planes that stand out in panchromatic frames can be sharpened in color pictures. Many satellite sensors also capture overlapping scenes, and computer processors then create detailed mosaics.

“It’s very common for Earth-imaging companies to bring in the information from multiple images to create a composite image that has better resolution and better dynamic range than any one of the originals,” Dyrud says.

BlackSky’s standard image products at 1-meter resolution do not rely on this layering technique, but customers can request it to enhance imagery, Merski says.

Euroconsult, a space consulting firm based in Paris, predicts the market for Earth observation data drawn from satellites will grow from $1.7 billion in 2017 to $2.4 billion in 2027. And that’s just for imagery.

Value-added services, like crop forecasts, that interpret the imagery could be a $9 billion market, Euroconsult says in “Satellite-Based Earth Observation: Market Prospects to 2027,” a report published in October 2018.

So it’s not surprising BlackSky and the ISR group are reluctant to share too many details. “A lot of people are exploring how to capture this market,” Merski says. “People are looking at building architectures like ours.

“Any error, be it vibrational jitter or tracking error, shows up as blur. If the tracking error is large enough, then you may miss the imaging target entirely.”

Andrew Maurer, Honeybee Robotics engineering director

About Debra Werner

A longtime contributor to Aerospace America, Debra is also a correspondent for Space News on the West Coast of the United States.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.