Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

The Pressure Gain Combustion Technical Committee advances the investigation, development and application of pressure-gain technologies for improving propulsion and power generation systems and achieving new mission capabilities.

Research into pressure gain combustion, PGC, continued to focus this year on power generation, propulsion and rocket applications. NASA awarded three new contracts for research on rotating detonation rocket engines, a Phase 1 Small Business Technology Transfer award for RDRE diagnostics and supported three Space Technology Research Fellowships.

In June, the European Commission funded the INSPIRE program, short for inspiring pressure gain combustion integration, research and education. Participants from five European countries and the United States will recruit 15 doctoral students to conduct research on PGC engines. The European Space Agency awarded a contract to a consortium led by the von Karman Institute in Belgium to numerically and experimentally investigate pulse detonation technology for spacecraft thrusters and significantly increase the lifetime of the spacecraft attitude control systems through its competitive express procurement process. The research started in July.

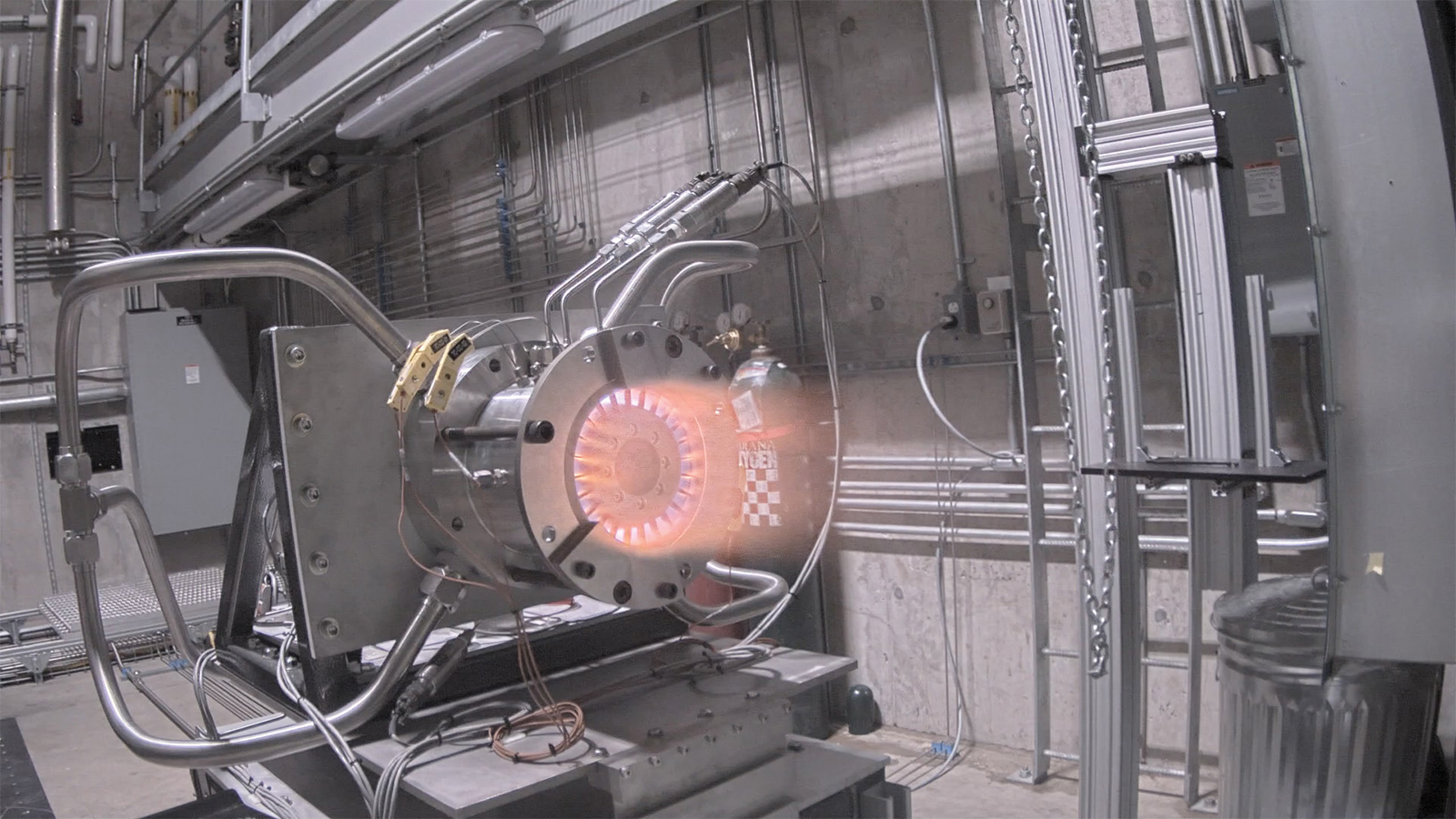

INSpace LLC and Purdue University of Indiana, with funding from the U.S. Air Force Research Laboratory, developed and tested a new high-pressure 5 Klbf-class (5,000 pounds of force) RDRE combustor employing direct liquid oxygen injection.

Aerojet Rocketdyne developed air-breathing rotating detonation engine analytical tools and hot-fire components under government and internal sponsorship to demonstrate operability across a broad range of flight conditions with advanced fuels.

In July, the University of Alabama perfected particle image velocimetry at 100 kilohertz to measure the highly periodic, subsonic-supersonic flow field at the RDE exit to identify localized flow segments that tend to diminish the trust performance. Concurrently, UCLA researchers pioneered high-speed, megahertz, optical diagnostics for in-situ pressure, temperature and species measurements in annular RDRE flows using tunable midwave infrared lasers, enabling quantitative in-situ diagnostics to look beyond wave-speed and thrust.

Researchers at the Naval Postgraduate School in California, characterized combustor inlet-nozzle area ratio effects and the importance of chamber gap width on delivered pressure gain. In early 2020, California State Polytechnic University Pomona designed and tested two deflagrative pressure gain combustion systems in collaboration with the U.S. Air Force Institute of Technology. Since February, two Purdue University student teams have been collaborating with the U.S. Department of Energy to integrate a supersonic axial turbine with RDE and optimized diffusers. Having PGC chambers coupled with turbomachinery can significantly augment the performance of gas turbine engines. Such research activities pave the way to future engines architectures based on PGC.

In January, scientists at the Semenov Federal Research Center in Russia developed a detonation afterburner, installed it on a TJ100S-125 jet engine and ground tested it. The results showed a 30% reduction of specific fuel consumption in comparison to conventional afterburners. A pulse detonation hydro-ramjet was also developed at the center to create periodic water jets to propel sea vessels. Direct benefits of PGC on the propulsion systems and subsystems may widen its application on aerial and naval vehicles in the future. In Japan, Nagoya University and its partners including JAXA, the Japan Aerospace Exploration Agency, fabricated the flight model of the detonation engine system for the sounding-rocket S-520-31 spaceflight test scheduled for 2021.

Also during 2020, researchers at NASA’s Glenn Research Center in Ohio investigated resonant pulse combustion and RDE systems for application to gas turbine engines and RDREs using numerical simulation. The U.S. Naval Research Laboratory focused on the wave dynamics of hollow and flow-through RDEs; first by replacing the center body of a baseline RDE with either a head-end wall or flowing an inert gas through the center, and then taking a more representative RDE for propulsion and attaching a convergent-divergent and an aerospike nozzle to the combustion chamber. Throughout the year, the laboratory worked with the University of North Carolina at Charlotte on detonation wave instabilities within an RDE, and with the University of Alabama on radial RDE’s to improve thrust performance for rocket applications.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.