Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

The Multidisciplinary Design Optimization Technical Committee provides a forum for those active in development, application, and teaching of a formal design methodology based on the integration of disciplinary analyses and sensitivity analyses, optimization, and artificial intelligence.

In February, Bruce Goldsmith Design designers and the University of Michigan’s Multidisciplinary Design Optimization (MDO) Lab disclosed a collaboration that led to the development of the Bruce Goldsmith Design Diva 2 production paraglider, certified and released in June 2024. They used OpenAeroStruct, a tool jointly developed by the MDO Lab and NASA’s OpenMDAO team.

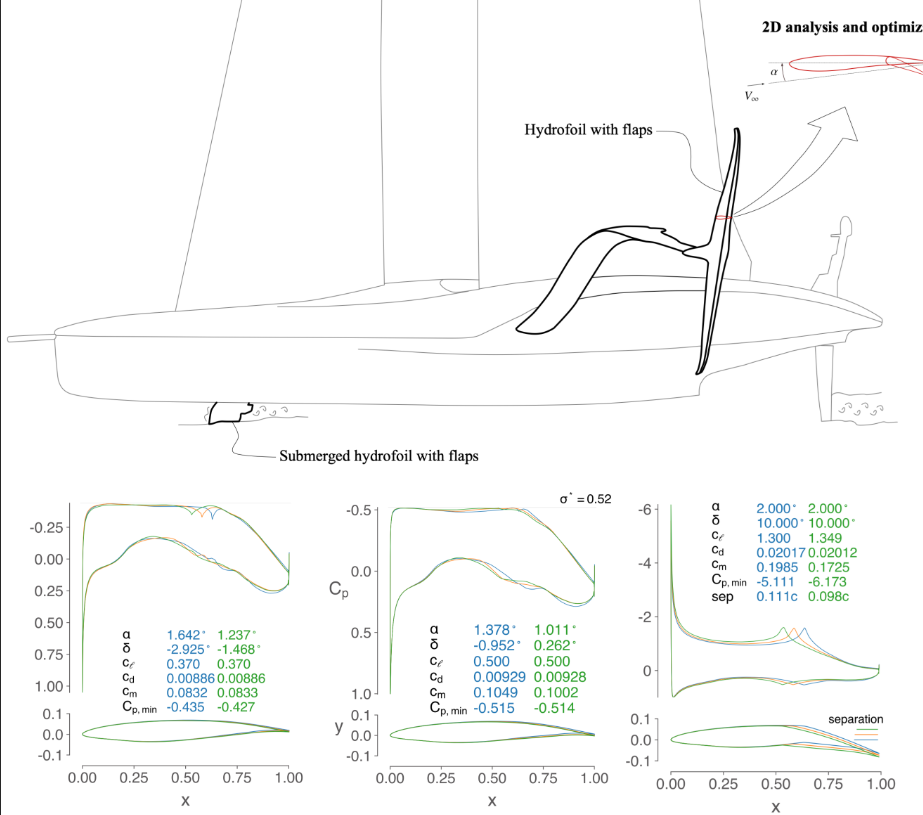

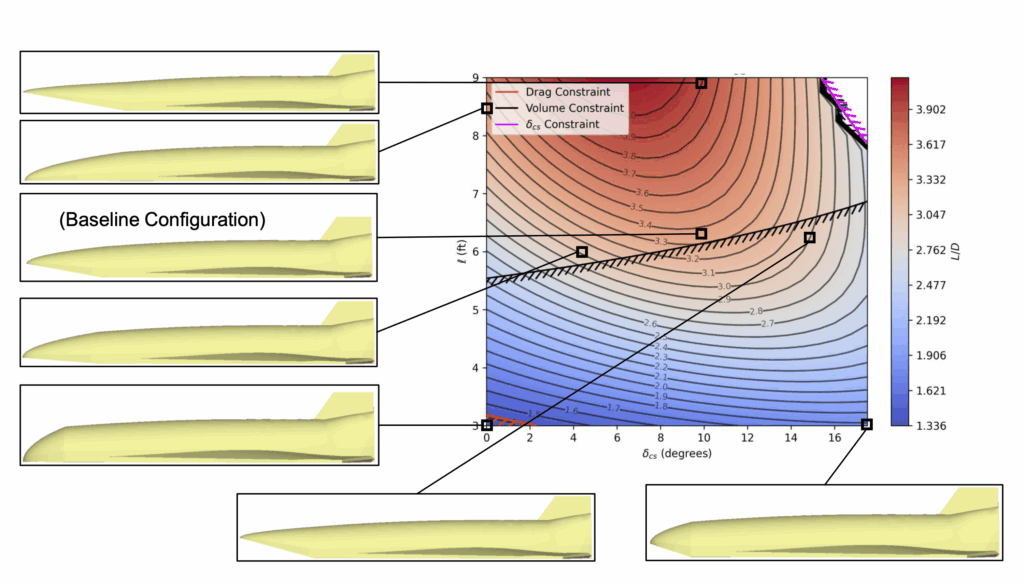

Also disclosed in February was Supercritical Inc. use of computational fluid dynamics (CFD)-based aerodynamic shape optimization to design hydrofoils for American Magic’s AC75, which competed in the America’s Cup in October 2024. Engineers designed high-performance subcavitating hydrofoil sections with flaps using multipoint shape optimization with cavitation constraints for speeds exceeding 50 knots. They performed the optimization through MACH, an open-source framework for aerodynamic and aerostructural optimization.

In June, the Uncertainty Quantification team at NASA’s Goddard Space Flight Center in Maryland performed global sensitivity analyses for an X-ray mirror assembly using NASA’s Quantification of Uncertainty Analysis Toolkit. QUAnT employed multifidelity modeling and efficient sampling techniques to identify design risk drivers at an estimated cost 1,000 times lower than state-of-the-art methodologies.

In July, Stratolaunch and Purdue University concluded a two-year multidisciplinary research effort that addressed the critical challenge of reducing the design cycle program times of hypersonic vehicles. An outcome of that work included a multidisciplinary design analysis and optimization (MDAO) framework using low-fidelity models of Talon-P, a conceptual reusable, rocket-powered, hypersonic flight testbed vehicle, inspired by Stratolaunch’s Talon-A.

In August, the Intelligent Design Optimization group at Virginia Tech developed an open-source, differentiable ship-design MDO stack that couples Holtrop-Mennen resistance, Wageningen B propulsor interaction, and a 3-degree-of-freedom maneuvering model set with event-style maneuvering constraints. The framework enforces targets such as a 90-degree heading change via normalized-time integration and root-finding using differentiable solvers in CasADi, introducing the outputs of time-domain simulations in a smooth and differentiable manner, suitable for efficient gradient-based optimization using the Interior Point Optimizer. Fincantieri Marine Group partially supported this work.

In September, the Multidisciplinary Analysis and Design (MAD) Center at Virginia Tech, in collaboration with SyntosIntelli, developed an approach to designing a uncrewed aerial vehicle that is safe for operations over people, pursuant to FAA classification, to protect persons and property. This was achieved under the Programmed Disassembly Project by using controlled and intentional separation and descent of the individual modular segments that comprise the aircraft.

In addition, in collaboration with M4 and San Diego State University, the MAD Center in November developed a manufacturability-informed optimization framework for curvilinearly stiffened tow-steered composites that maximizes structural performance while minimizing weight. The framework simultaneously optimizes fiber path orientation and curved stiffener layout while preventing manufacturing defects such as gaps, overlaps and excess curvature common in automated fiber placement. Current improvements included lamination parameters and analytical gradients to enhance design efficiency for aerospace industry implementation. The MAD Center finally developed a reduced-basis approach using affine decomposition to significantly reduce central processing unit time and memory requirements for variable stiffness panel optimization.

In September, a group of researchers at the University of California San Diego was awarded a new investigatory center, the Center for Simulation and Design of Heterogeneous Architectures for Performance and Energy Absorption (SHAPE), sponsored by the Predictive Science Academic Alliance Program of the National Nuclear Security Administration. The SHAPE Center collaborates with the San Diego Supercomputing Center and Colorado School of Mines to enable large-scale topology optimization for complex nonlinearities, exploring memory efficient computation, novel solver technology, uncertainty quantification and scientific machine learning, tailored for accelerated processing unit hardware systems. SHAPE’s software output will be applied to explore and discover new nonlinear metamaterial designs that can mitigate high-strain-rate impacts.

Contributors: Rakesh Kapania, Alicia Kim, Leifur Leifsson, Joaquim Martins

Opener image: An air-to-air photo of the Bruce Goldsmith Design Diva 2 in Chamonix, France. Credit: Joaquim R. R. A. Martins and Lucas Bonin

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.