Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

The Structural Dynamics Technical Committee focuses on the interactions among a host of forces on aircraft, rocket, and spacecraft structures.

In March, the U.S. Air Force Research Laboratory in Dayton, Ohio, assembled and tested a new pitch-plunge wind tunnel mount. The new apparatus, which enables a model to move freely in the tunnel and respond to structural and aerodynamic loads as if it were in flight, was tested in the Parker Subsonic Research Facility wind tunnel at Wright-Patterson Air Force Base in Ohio. This tunnel has the capability to measure complex structural and fluid dynamics to study aeroelastic interactions of scaled flight vehicles. For the first test campaign, a half-span model of the X-56 aeroelastic testbed was designed and 3D printed to behave with scaled structural and aerodynamic similarity to the full-scale flight vehicle. A controller to “fly” the vehicle in the tunnel was also developed.

Also in March, the Planetary Aeolian Laboratory at NASA’s Ames Research Center in California completed testing of a next-generation Mars helicopter rotor. Designed by NASA Ames, the University of Maryland, NASA’s Jet Propulsion Laboratory, AeroVironment and Tohoku University, the rotor blades were built to be paper thin (1% thickness-to-chord ratio), with unique airfoils for low Reynolds numbers and high transonic tip Mach numbers, and a spar-less construction. They could expand Mars aerial exploration beyond what was achieved with the Ingenuity helicopter by enabling larger helicopters to carry out science missions.

In May, a dynamically scaled 1.45-meter-diameter hingeless hub proprotor was tested in the University of Maryland’s Glenn Martin wind tunnel at speeds up to 100 meters per second—equivalent to 230 m/s full scale—proving the feasibility of high-speed tiltrotors free from whirl flutter. Current tiltrotors with gimballed hubs are susceptible to whirl flutter aeroelastic instabilities, which may lead to system failure after a critical speed. Hingeless hubs can enable safer electric vertical take-off and landing aircraft and larger turboprops that are runway independent.

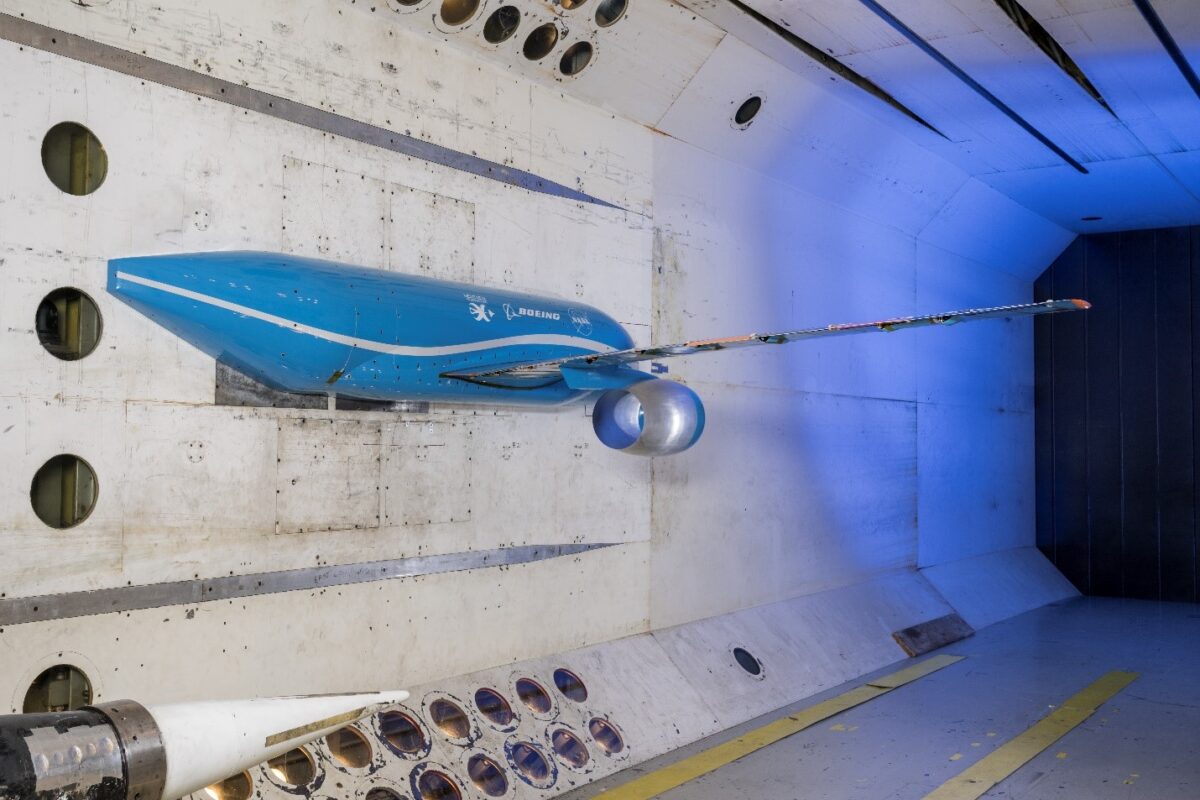

In June and July, a NASA and Boeing team completed testing of the Integrated Adaptive Wing Technology Maturation wind tunnel model in NASA Langley Research Center’s Transonic Dynamics Tunnel in Virginia. In this project, part of the NASA Advanced Air Transport Technology and Advanced Air Vehicles Program, Boeing partnered with NASA to design, build and test a 4-meter half-span aeroelastically scaled model. The test goals were to demonstrate technologies for active control of flexible, thin wings. Closed-loop controllers were tested targeting real-time drag minimization, maneuver load alleviation, gust load alleviation, and active flutter suppression. This research will benefit the U.S. aviation industry through improvements to aircraft performance and safety and through advanced control methods integrated into future thin-winged aircraft.

In September, TU Berlin and the Institute of Aeroelasticity of the German Aerospace Center (DLR) completed wind tunnel testing of the flexible and very flexible TU-Flex wings in Göttingen, Germany. TU-Flex is an aircraft demonstrator developed by TU Berlin to study the interaction between aeroelasticity, flight dynamics, and control laws. The tests provided data for aeroelastic model tuning and demonstrated a maneuver load alleviation controller. Ground testing of the complete demonstrator was conducted in October, and the first flight is planned for 2026.

Also in September, Skydweller Aero Inc. completed significant flight testing with its Boeing 747-sized test aircraft from Stennis International Airport in Mississippi. The testing, which took place in February, July and September, included uncrewed flights exceeding 74 hours in duration, more than 222 hours in 20 days in July (47% of the time in the air), and with a total flight time of more than 300 hours. Throughout the flights, Skydweller’s technology for gust sensing and encounter aeroelastic response was extensively researched and proven. The aircraft navigated multiple flight paths in the vicinity of storms, withstanding significant gusts and showing unprecedented robustness in a solar uncrewed aircraft.

Contributors: Greg Caires, Anubhav Datta, Pedro Gonzalez, Jared Grauer, Patrick Heaney, Kevin McHugh, Robert Miller, Rubén Moreno, Flávio Silvestre, Travis Vetter

Opener image: The Integrated Adaptive Wing Technology Maturation wind-tunnel model in the NASA Langley Research Center’s Transonic Dynamics Tunnel. Credit: NASA

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.