Inside one company’s moon-landing proposal

By Cat Hofacker|September 16, 2020

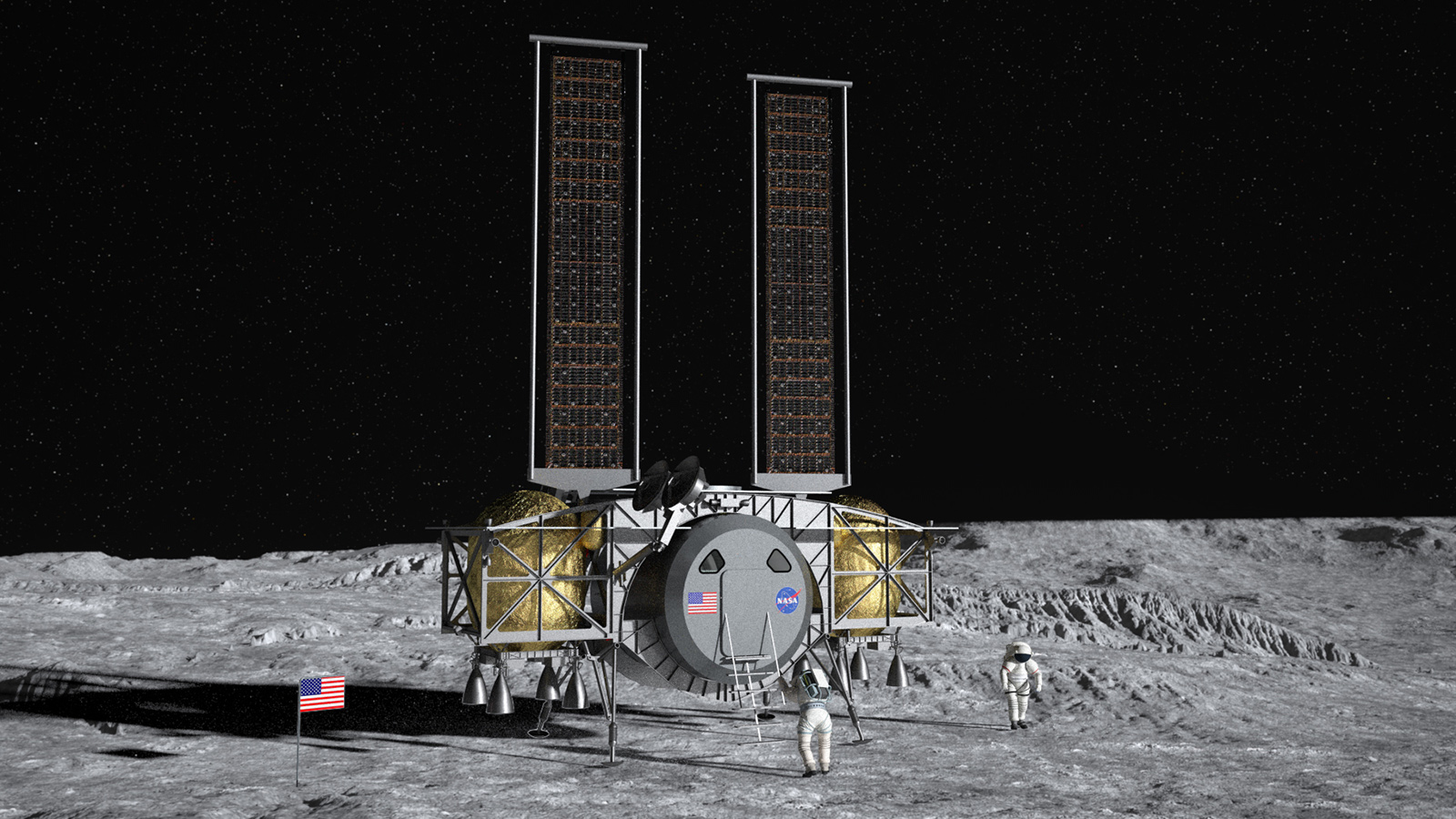

Dynetics views a reusable two-element lander as key to affordable lunar exploration by NASA

Dynetics, the Alabama firm that is competing for a NASA contract to make a lander that would deliver astronauts to the moon, is mixing inspiration with technical details as it makes the case for why it should be chosen in February as one of the companies that will manufacture landers for the 2024 mission and subsequent landings.

The Dynetics Human Landing System, or DHLS for short, whose concept the company is refining under a $253 million NASA contract, would be a low-slung lander standing about 1.5 meters from the ground, according to an animated video of the lander that the company released online Tuesday, before executives participated in an AIAA webinar about lunar exploration technologies.

By contrast, rival Blue Origin proposes building a roughly 12-meter-tall lander requiring a much longer crew ladder, according to a rendering and dimensions released earlier this year, and a mockup delivered to NASA’s Johnson Space Center in Texas last month. Also, SpaceX’s Starship spacecraft, an early prototype of which exploded in May after founder Elon Musk tweeted gleaming pictures of it, would be equipped with an elevator that the crew would ride down to the lunar surface and back.

NASA plans to hire at least two of these companies, or maybe all three, to move into the construction phase of the $35 billion Artemis program.

Dynetics wants to win, in part, by articulating a bold vision of reusability that would propel the company beyond the initial 2024 landing. That landing and those that follow would work like this: Autonomous navigation software developed by Draper of Massachusetts would steer the reusable lander toward the surface while two external fuel tanks that will replenish the fuel consumed during the powered descent from lunar orbit are jettisoned. The two astronauts (though the design could accommodate four) would monitor the progress via small windows on either side of a circular hatch, ready to manually take over if necessary via joysticks and throttle controls underneath the windows.

Once the astronauts climb down the 1.5-meter ladder and move a safe distance away, the lander would fire its engines with the remaining two fuel tanks and return to lunar orbit to ferry more passengers or a load of cargo. This approach maximizes “the utility of our lander to meet NASA’s mission needs, but also to attract other users who wish to explore and work on the moon,” said Kathy Laurini, the lander payload and commercialization lead at Dynetics, during the AIAA webinar.

She asked viewers to flash forward to the year 2026, when the historic Artemis 3 landing has been accomplished and astronauts are working on the moon near their Dynetics lander. Another lander would descend and deploy a ramp, down which several rovers roll. The lander would then fold up the ramp and fire its engines, returning to lunar orbit to await the next rover or round of cargo. By 2030, “Artemis Base Camp has become a reality,” Laurini said. Astronauts and rovers would be joined by other structures including habitats and refueling stations, where future Dynetics landers could refill their propellant tanks.

“Having the ability to fill our liquid oxygen tanks on the lunar surface could enable new mission classes, like hopping around to other parts of the moon to accomplish some key science objectives,” she said.

Kim Doering, vice president of space systems at Dynetics, underscored the long-term focus as she narrated the video of the DHLS in action: “Not only are we designing the Dynetics HLS [human landing system] to achieve the 2024 crewed mission, we are designing for future missions too with as few changes as possible,” she said.

The Dynetics design would consist of a tube-shaped crew module to be built by Thales-Alenia Space. This would be fitted before launch inside a rectangular spacecraft that during an on-orbit maneuver would receive two external propellant tanks on both sides of it. Dynetics intends for the crew module and spacecraft to be reusable, but new propellant tanks would be attached in lunar orbit before each landing via on-orbit refueling.

Initially, this refueling would require three Vulcan Centaur rockets from United Launch Alliance, Doering said: one rocket to launch the lander to lunar orbit, and another two rockets to each launch one of the propellant tanks. For the 2024 landing, the rockets’ upper stages would transfer the propellant tanks by means Dynetics has not yet described publicly to the lander. From there, the lander would dock directly with an Orion capsule that would be launched with a crew ahead of time.

Employees from Dynetics and its rivals will continue working with teams of NASA employees to refine their lander designs ahead of the February selection.

Related Topics

Human Spaceflight