Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

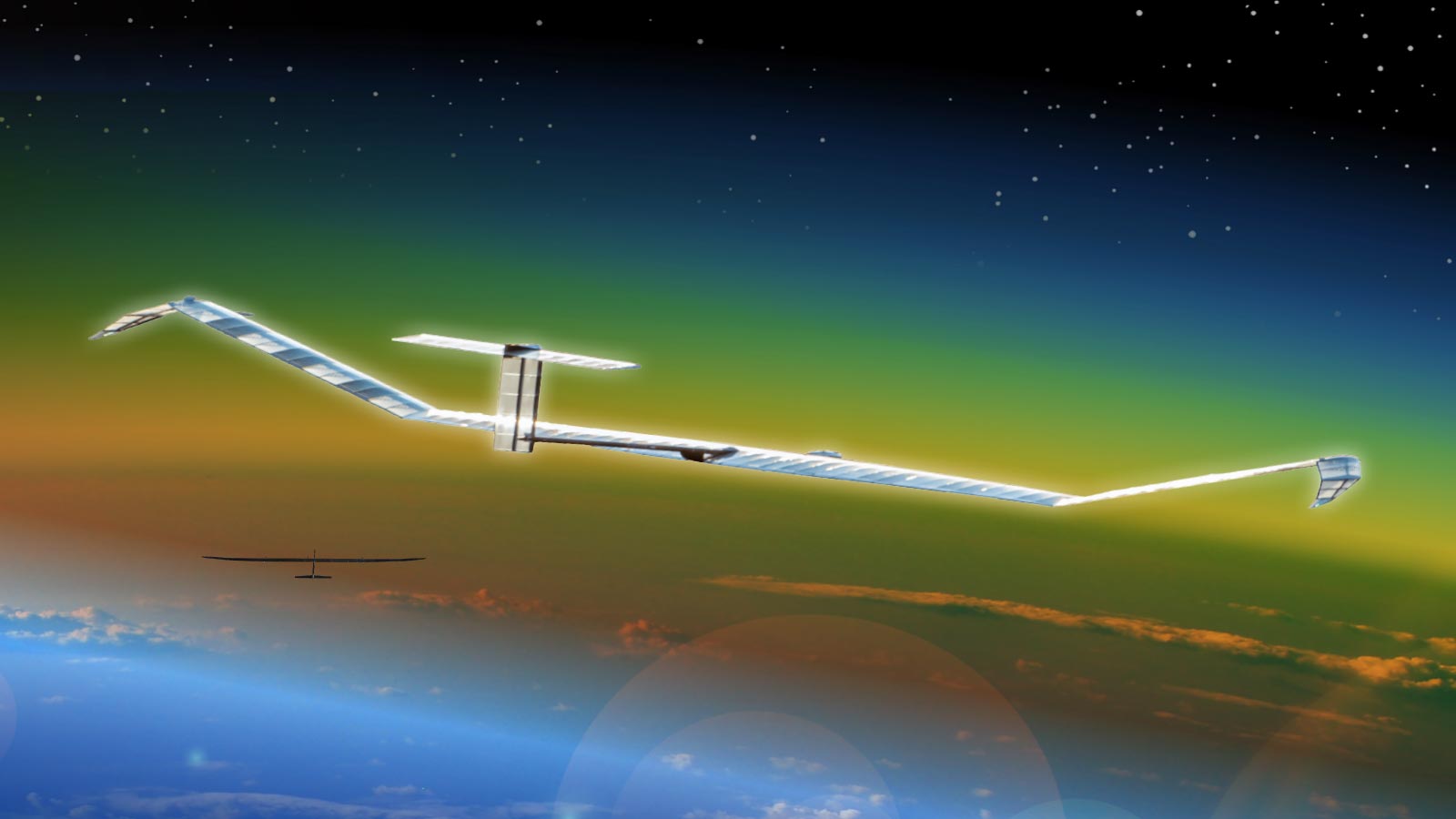

For decades, aircraft makers have sought to fly their wares high over cities for days, weeks or months at a time to provide services traditionally left to satellites. Now, the first stratospheric services are here, with balloon companies leading the way, though they could soon be joined by fixed-wing aircraft that would stay aloft for months. Paul Marks takes the measure of the market and the coming aircraft.

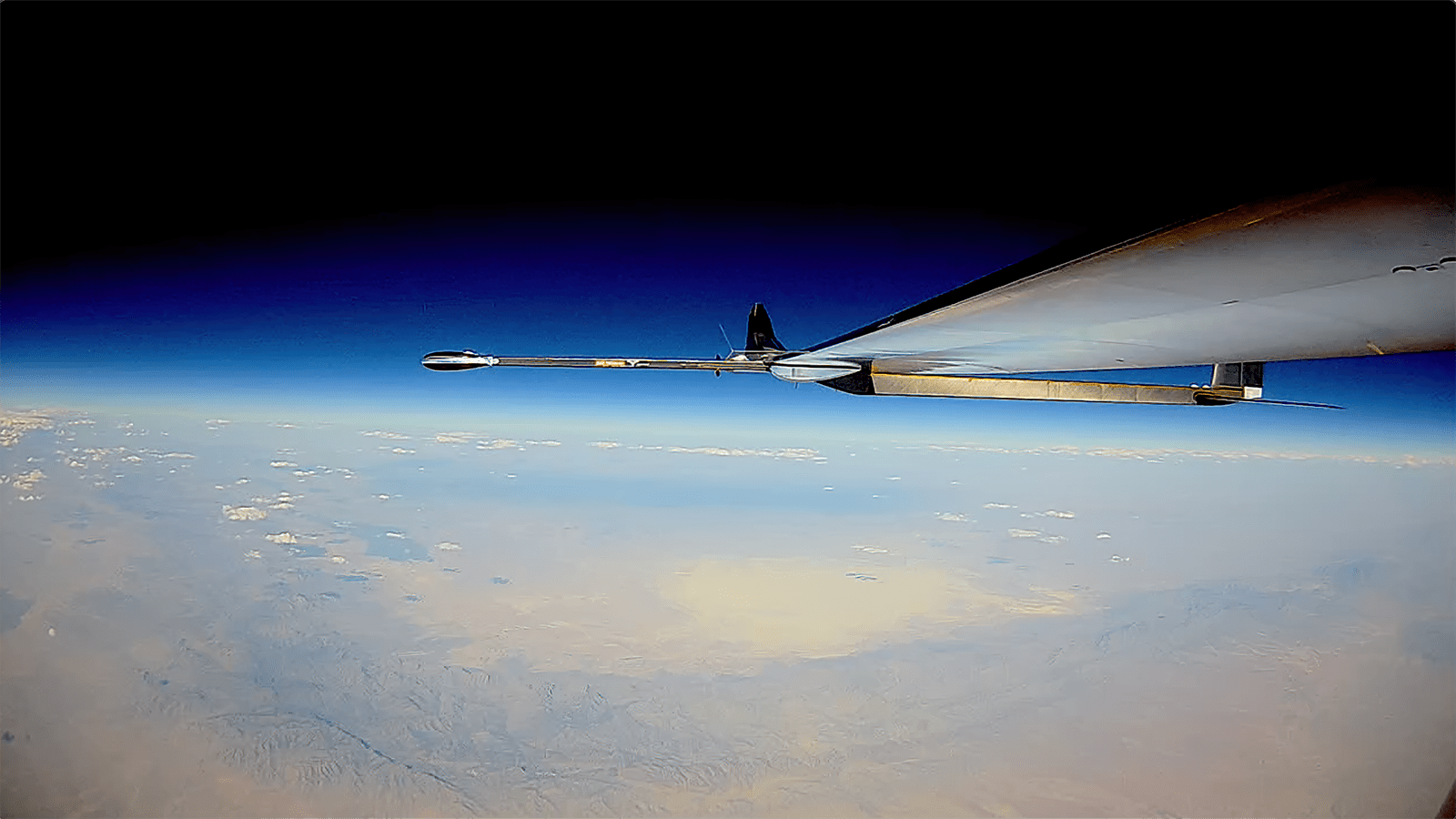

Grasping the elongated wings of a skinny, ultralight aircraft, a posse of aviation engineers ran along a dusty, desert runway at the U.S. Army’s Yuma Proving Ground in Arizona. The fragile drone’s 25-meter-long wings bit into the air, and when the runners let go, the twin propellers pulled the craft into an achingly slow climb at bicycling speed — 37 kilometers per hour, or 20 knots. Its destination? The calm, rarified air of the stratosphere, at altitudes between 60,000 and 70,000 feet, where it arrived about 10 hours later.

This moment in June 2022 was the start of a 64-day flight by a Zephyr Z8, which, as its name suggests, was the eighth design of a solar-electric aircraft originally spawned by U.K. military research firm QinetiQ in 2001. The design’s evolution is emblematic of the decades-long struggle by a succession of innovators to orbit aircraft of various kinds high above cities, far-flung military bases or battlefields to provide communications or beam down optical imagery, lidar or radar data.

Let’s start in 1999. There was the piloted, large wingspan HALO-Proteus twinjet, a prototype of which was built by Burt Rutan’s Scaled Composites company to show how internet could be delivered by aircraft. There were plans for uncrewed blimps proposed by former U.S. Secretary of State Alexander Haig and his son, also for internet delivery. There was AeroVironment’s Helios, a segmented prototype flying wing that came apart in spectacular fashion in 2003 over the U.S. Navy’s Pacific Missile Range. There was HALE-D, Lockheed Martin’s unoccupied High Altitude Long Endurance Demonstrator, a silvery airship that in 2011 became stuck at airliner cruising altitudes on its way to 60,000 feet, forcing operators to partially deflate it and ditch it in a Pennsylvania forest as news cameras rolled. As for Zephyr, QinetiQ flew the aircraft for the U.S. Department of Defense and the U.K. Ministry of Defense from 2008 to 2010 under a short-lived DARPA program called Vulture that aimed to provide persistent surveillance and communications for troops in Afghanistan and Iraq.

Interest and technical progress did not entirely vanish, and first into business in the stratosphere were companies offering remote-sensing services from balloons. The list includes Arizona-based World View and New Space Labs at the Brooklyn Naval Yard in New York. Now, developers of at least two fixed-wing stratospheric designs are attempting to enter the market. There is Zephyr and also a larger solar-powered plane, PHASA-35 (pronounced like the Star Trek weapon).

Technical breakthroughs are partly responsible for the resurgence in the field of HAPS, variously spelled out as high-altitude platform station or high-altitude pseudo satellite. Lightweight solar cells, batteries, miniaturized GPS sensors and inertial measurement units and other technologies have “brought back balloon-based approaches to the toolset of systems architects when only satellites, drones or helicopters were considered before,” says Rema Matevosyan by email. She is CEO and co-founder of Near Space Labs, which in 2021 began selling change detection imagery to insurance providers.

For the fixed-wing makers, the big challenge is getting through the night over and over again for months at a time, given that staying aloft counts on gliding on their long wings and turning their electrically driven propellers. They must therefore capitalize on advances in solar cell materials and battery management technology.

So why is the stratosphere worth it? Operating at such altitudes avoids the troposphere’s turbulent weather and, once the aircraft reaches those altitudes, there is no need to deconflict with air traffic. When the application is remote sensing, finer ground resolution can be produced than if the same cameras were higher up in space.

“Stratospheric imaging offers very high-fidelity imaging at a massively lower cost,” says Keith Masback, an investor in Near Space Labs and a former U.S. intelligence executive in the imagery field. A payload does not have to be built to “endure a violent and costly launch, nor does it need to be hardened against radiation and the temperature extremes of space,” he adds.

Also, establishing an unblinking eye in space requires sending an instrument to geosynchronous orbit 35,000 kilometers above the equator. By contrast, a pseudo satellite provides an unblinking eye at far lower altitudes, plus other flexibilities.

“Persistence over a chosen location for months at a time enables a pattern of life to be observed, and unlike satellites, our aircraft can be repositioned to other areas of interest,” says Bob Davidson, CEO of Prismatic Ltd. in Alton, U.K., maker of the PHASA-35. The fixed-wing, solar-powered design is slated to go into low-rate production in time to start services in 2028.

“Furthermore, the aircraft will return to base at the end of a mission enabling overhaul and payload swap before relaunch — features simply not possible with satellites,” he says via email.

For internet or other communications services, the signal latency is less severe than when signals must transit from space. Consider an aircraft operating at an altitude of 20 kilometers (65,600 feet), Davidson says. That’s 20 times closer to Earth than the International Space Station. In addition to lower latency, this affords “a capability to connect direct to off-the-shelf hand-held devices such as mobile phones.”

Another reason for the current resurgence is the runaway interest in orbital internet connectivity spurred by Starlink, OneWeb and Amazon’s planned Project Kuiper constellation, and the interest in imagery sparked by Planet, the San Francisco remote sensing company. That interest has reached almost crazy levels: In figures the International Telecommunication Union computed for me last October, the United Nations-affiliated organization said that it now holds registrations for what could theoretically amount to 1.7 million satellites in low-Earth orbit by 2030.

Some or perhaps many of those could be placeholder registrations for grandstanding nation states or businesses that might not succeed, but regardless, the magnitude of the interest in LEO should worry people, says Samer Halawi, CEO of AALTO HAPS, the Farnborough, U.K., company created by Airbus in 2022 to commercialize the Zephyr technology, which Airbus purchased from QinetiQ in 2013.

The reason? The denser LEO gets, the higher the risk that collisions creating orbital debris will occur.

“It’s ridiculous. No one has been able to solve the space debris issue, and at some point we’re going to experience Kessler Syndrome, with space debris created exponentially,” Halawi says. “One small piece will hit something and end up creating millions of pieces, and it will just get worse and worse. That could bar access to space once there is enough debris mass. It’s really scary.”

Even as they compete with satellites in some regards, some HAPS providers including AALTO will actually need them to command and control the aircraft they plan to station around the world. Halawi says AALTO is also planning optical satellite links for future services so that, say, an Earth observation payload on a Zephyr can quickly beam up its data to a satellite for onward hops through a satellite network to a ground destination.

Thinking back to his intelligence role, Masback says by email that he advocates for “a healthy mix of airborne (crewed and uncrewed), stratospheric balloon, and space-based imaging (government and commercial).”

That said, Halawi also thinks LEO networks are inefficient by design for some purposes because they “spread the constellation’s capacity all over the world, uniformly.”

“So you and the penguins in Antarctica all have the same level of capacity,” he says. “That’s not efficient use of the system, and you can’t scale it up. But with HAPS, we can do that efficiently, in a scalable way and with very high capability.”

Claims are one thing, of course, performance quite another. In 2004, Zephyr made an inauspicious start with a flight of 27 minutes; but in 2007, another Zephyr flew for two days and six hours, then 14 days in 2010. The Z8, an updated design, made its debut in 2018 by flying for 26 days.

“That was a hugely significant maiden flight, and it demonstrated that all the key enabling technologies were finally mature enough to close the delicate energy budget in the stratosphere and make HAPS a reality,” says Paul Stevens via email. He was head of design on the Zephyr program until 2020, and is now CEO of Voltitude, a Farnborough, U.K.-based HAPS research startup.

Four years after the inaugural flight, the posse of engineers released the latest Z8 from Yuma, and AALTO’s remote pilots steered it over oceans and (with permission) into South American airspace, achieving 64 days before the sylph-like aircraft broke apart in punishing turbulence as it attempted to return to Yuma, for reasons that will become apparent.

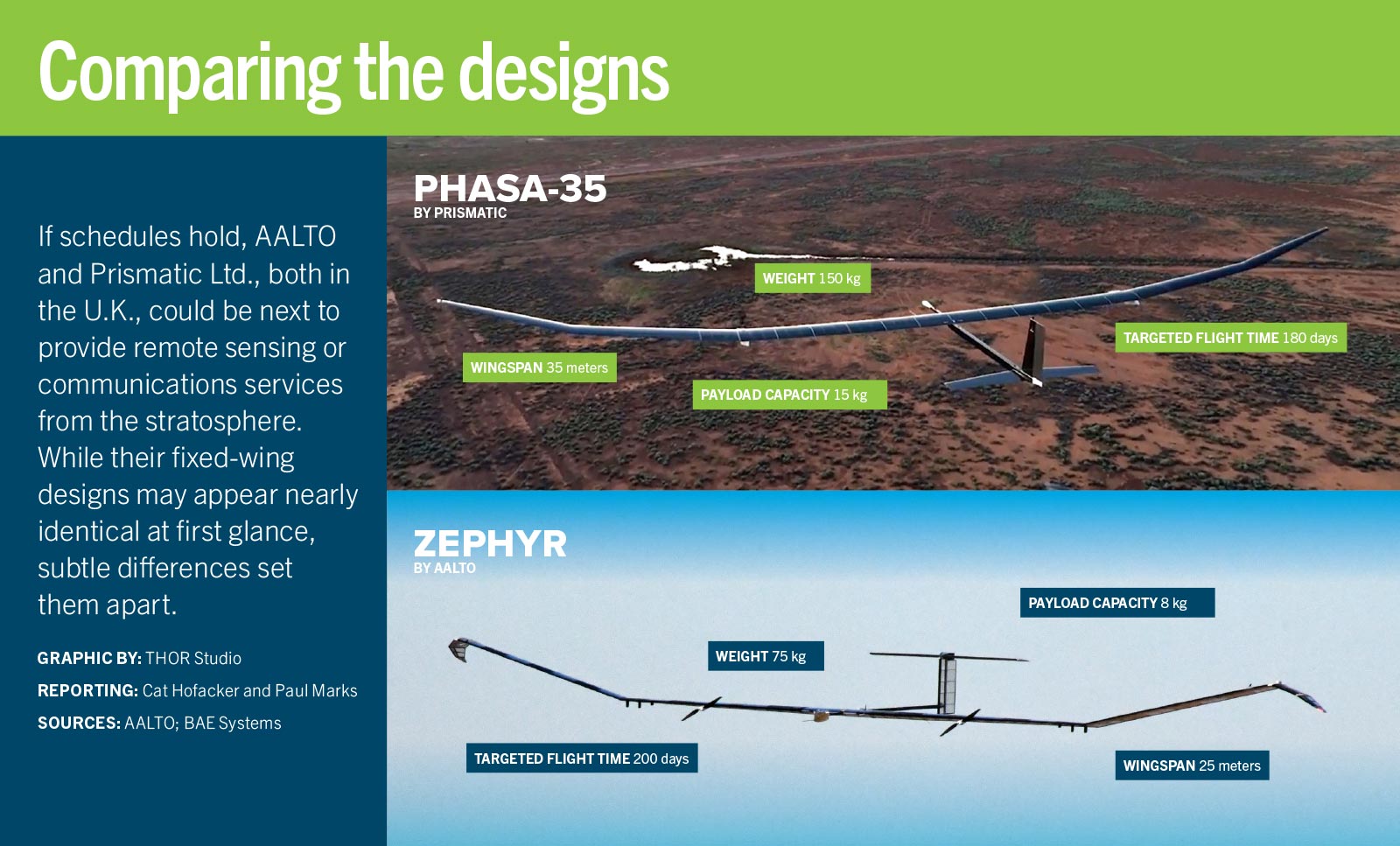

A year later, Prismatic completed its first stratospheric flight with a PHASA-35. It resembles Zephyr except that it’s a bigger beast, with a wingspan of 35 meters and a payload capacity of 15 kilograms, compared to 25 meters and 8 kg for Zephyr. PHASA-35 spent at least four hours of its day aloft at 66,000 feet after lifting off from the company’s U.S. base at Spaceport America in New Mexico. The remote pilots landed the craft safely, dead on the runway centerline, concluding the 24-hour technology-proving mission.

Ideally, AALTO wants to achieve 200 days persistence, while Prismatic is striving for around 180 days. Both firms say they are on the way to achieving the numbers they need. AALTO, for instance, says that it has already run its ultrahigh-energy-density lithium-ion battery packs through 180 days of charge-discharge cycles in ground tests.

Still other firms are considering much bigger HAPS designs so they can cram ever more cellphone antennas and remote sensing kits on board. SoftBank Corp. of Japan has built a 78-meter-wingspan solar-electric HAPS called Sunglider. In 2020, it flew for five and a half hours, reaching 62,500 feet with its 10 electric propellers. Meanwhile, a Cambridge, U.K., startup called Stratospheric Platforms Ltd. is designing a 60-meter-wingspan High Altitude Platform, which it hopes to power with hydrogen fuel cells to avoid the charge-discharge timing dictated by the solar day-night charging cycle. It has yet to be built, however.

These larger HAPS won’t be taking to the air via Wright-brothers-style hand launches like Zephyr does, and for good reason. For instance, each PHASA-35 will make a motor-powered takeoff roll on detachable landing gear that are jettisoned after takeoff and reused on the next flight, thus ridding the aircraft of redundant wheel mass. Each “lands on sacrificial material on the underside of the motor pods instead,” says Davidson. “Hand launch is not practical or safe for larger HAPS vehicles. As vehicle mass increases so does take off speed, ultimately beyond that which a ground launch crew can sustain.”

While there is no shortage of inventive minds in the HAPS arena, for a long time there was a shortage of something else: investment. An example of change afoot came in June, when a consortium of Japanese telecommunications and satellite television companies led by mobile phone and wireless internet pioneer NTT Docomo, Japan’s biggest wireless telecommunications firm, announced a $100 million investment in AALTO.

NTT Docomo and Space Compass Corp. said it wants to boost connectivity in Japan’s many islands and remote mountainous areas, using Zephyr aircraft as “nonterrestrial networks,” or NTNs. “We want to create a successful use case for Zephyr in Japan and then expand it to Asia,” says Koichiro Matsufuji, co-CEO of Space Compass Corp.

Of interest is the coverage area compared to a cell tower. “One Zephyr aircraft can provide cellphone coverage equivalent to 250 cellphone towers on the ground. That means we can provide connectivity in some remote places where there is no profitable way to develop ground networks,” says Pierre-Antoine Aubourg, AALTO’s chief technology officer.

Halawi, the AALTO CEO, says that one “tower” in the stratosphere can cover 7,500 square kilometers on the ground, serving 5G connectivity to up to 100,000 people in regions previously denied mobile coverage.

What is particularly interesting about the cellphone connectivity payloads on HAPS, Halawi says, is that they do not need to be complex. “Most of the technology is in a ground gateway located at the mobile operator. The technology in the aircraft payload bay is a very simple antenna known as a bent pipe, which mirrors the received signal. It takes the signal from a handset to the aircraft and then sends it to the gateway on the ground. And that gateway is where the intelligence and processing is done, so what happens in the aircraft is not power hungry.”

Japan was also attracted by the fast setup of communications services when typhoons, earthquakes and tsunamis strike. “In Japan, there are a lot of natural disasters,” Halawi says. “So having an aircraft that can come up and be deployed very quickly avoids having to drive a network’s trucks through difficult terrain after a natural disaster.”

What exactly has convinced the ultralight solar-electric aircraft builders, and this first tranche of investors in Japan, that this is now all possible from ultralight remotely piloted aircraft systems? For Stevens at Voltitude, with two decades of experience designing Zephyr variants, it is the coming together of solar arrays that generate enough watts per square meter of their area, with rechargeable lithium-ion batteries that produce sufficient watt-hours per kilogram, to allow persistent electric flight.

“These two key enabling technologies are ready and sufficient now. So, with the right system engineering skills, it is possible to design and operate very low wing-loading aircraft in the stratosphere, perpetually, on solar power,” Stevens says.

AALTO said that what has also made all the difference is “effective energy management” between the solar array, the batteries and the twin electric motors. The company added that achieving “the battery capacity required to maintain continuous flight through the night has been crucial to creating sustained operations.”

For its part, Prismatic says that the difference is the arrival of “high energy density battery cells, which have moved from the lab to high volume production.” Both PHASA and Zephyr use 450 watt-hour per kilogram lithium-ion batteries from Amprius Technologies of Fremont, California, the firm that is currently making the highest energy density cells available thanks to a proprietary silicon anode technology.

Having been convinced the technology is sound, the Japanese firms are not merely buying Zephyr aircraft, however.

“It’s an investment into the company, too, not just into what we’re doing in Japan,” says Halawi. “It will help us accelerate the industrialization and commercialization of the company, by making Zephyr production more volume-based, as opposed to prototype-based production, so that we produce the aircraft cheaper and faster.”

The company envisages beginning commercial Zephyr operations in 2026.

The investment also will help AALTO fund construction and development of what it calls its first “AALTOport” — a permanent mini-airport for assembling, testing and flying Zephyrs — which will be located in Kenya, in the Rift Valley. That might sound off the beaten track, but it does not matter much where a fixed-wing HAPS vehicle like Zephyr or PHASA enters the stratosphere because, it can fly, albeit slowly, to any location it needs to orbit once in the benign, sunlit uplands of the stratosphere.

AALTO, which has partnered with the Kenya Space Agency and the Kenya Civil Aviation Authority, both of whom are interested in exploring HAPS applications, hopes its AALTOport in Laikipia County, north of Nairobi — complete with “infrastructure, purpose-built runway, hangar, final Zephyr assembly line, operations centre and an administrative hub” — will be ready to begin hosting test flights by July 2025.

Prismatic, however, is staying in its Spaceport America location for now. “The New Mexico range has been invaluable in enabling the PHASA-35 to achieve stratospheric heights in 2023, and will continue to play an important part in future trials. But we will continue to review the location of flight trials, including the review of other regions where the weather offers a more benign and stable environment,” says the company in a statement.

For AALTO, why choose Kenya? The answer brings into sharp relief a key point — and currently a major downside — about the technology behind fixed-wing HAPS: The aircraft must have long, lightweight, high-aspect-ratio wings to generate adequate lift in the stratosphere, where the air density can be just 3% of that at conventional flight levels. But first, the flexible-winged pseudo satellite has to climb up through the troposphere to the stratosphere, powered by its motor-driven propellers.

And that’s a problem.

“The trick with stratospheric aircraft in general — and that’s not just for us but for everybody — is that you design the aircraft in a way that makes it glide in the stratosphere really well,” says Halawi. “And that’s usually a lightweight aircraft that has a certain simplicity to its design that allows it to glide for months at a time in the stratosphere.”

He goes on: “But what that prevents it from doing is flying up to the stratosphere and back down in rough weather, because it’s not designed to do that. Which means that to get to the stratosphere, which is pretty high up, you traverse different altitudes to get up there. And what you want is the weather at every altitude to be favorable, not just at the surface, and not just in the stratosphere, but at every altitude. And this is where it gets tricky.”

After undertaking detailed meteorological studies, AALTO identified Kenya as the location “that gives us a window to get up and down from the stratosphere about 10 months of the year,” says Halawi. “It’s probably one of the best places in the world for this. But it’s not enough because it’s not all year long.” So the long-term plan is to establish “a total of three or four locations will give us access to the stratosphere.”

“Once we’re in the stratosphere we can operate anywhere, we can go anywhere and operate anywhere. The tricky part is getting into it.”

And getting out of it. When AALTO tried to land its record-breaking Zephyr at Yuma in August 2022, it faced its nemesis. “The weather was not permitting us to land when the aircraft was getting to the end of its parts’ life. And we got hit with an incredibly high elevated storm,” says Halawi. “And at the same time, we were working in an experimental area, so we were very restricted in where we could fly, and so could not avoid the storm. It operated a lot better than we expected for a good couple of hours, but then we lost the aircraft.”

In response, AALTO designed an adaptive autopilot that can handle some adverse weather events.

Aircraft attributes

Developers of ultralight solar-electric aircraft for the stratosphere face competing design challenges. Their unoccupied aircraft must mainly glide in order to conserve enough electricity to make it to the next sunrise and achieve the goal of staying aloft for months on end. That requirement drives them to the lightest-possible structure, but that structure must also be strong enough to accommodate adequately sized batteries and solar array coverings, while also coping with any violent weather encountered in the troposphere on the way up and back.

PROPELLERS

When I spoke by video with Pierre-Antoine Aubourg, chief technology officer of AALTO, maker of the Zephyr aircraft, I did a double take when I noticed the propellers of the Zephyr behind him in AALTO’s Farnborough hangar. Having just reported on China’s cloning of NASA’s Ingenuity Mars Helicopter, I was very familiar with the distinctive shape of the rotors on the diminutive helo: Each consisted of very broad, very curved, scoop-like blades, to get purchase in a Martian atmosphere that’s just 1% the density of Earth’s. Zephyr’s 1.2-meter propellers were not only exactly the same size as Ingenuity’s rotors, they looked very similar in shape. “To work in the stratosphere in very thin air, the propellers must be of very high pitch. They perform terribly at low altitude,” says Aubourg.

That’s one reason for the aircraft’s miserly 20-knot, bicycle-speed climb after launch. I haven’t seen the props on Prismatic’s PHASA-35, but CEO Bob Davidson tells me by email: “There are indeed similarities with the Ingenuity Mars Helicopter given that the PHASA-35 operating environment is 3% of Earth air density and Mars is 1%.”

FUSELAGE

Because low mass and adequate strength are crucial, the structures of these aircraft are made of carbon-fiber reinforced plastic. These epoxy and fiber formulations must withstand the high ultraviolet radiation and ozone exposure in the stratosphere, the dramatic temperature swings between night and day, and the atmospheric pressure cycling of flying from the ground to the stratosphere and back. Aubourg, the AALTO technology chief, says Zephyr’s structure is based on composites supplied by the Toray corporation of Japan that are qualified for satellites. At Prismatic, Davidson says some materials in PHASA-35 are also qualified to satellite standards. He describes the structure as a “carbon fiber monocoque, point-loaded structure design with hard points for the motor pods and the payload.” All materials are test cycled through stratospheric temperatures and pressures to simulate flight conditions — typically “multiple days at minus 90 degrees Celsius and 3% of atmospheric pressure at sea level.”

WINGS

The gangly profile of Zephyr’s 25-meter wingspan and PHASA-35’s 35-m span share upward-slanting, or dihedral slopes, at their outboard ends. Zephyr’s wings have an extra feature, however: At the tip of its dihedral sections, each wing curves down again. Aubourg says computational fluid dynamics simulations show that this gives them the best possible aerodynamic performance in the stratosphere.

Prismatic, meanwhile, has some aspects geared for the journey to and from the stratosphere: “Features have also been incorporated to ensure that the aircraft can withstand tropospheric flight conditions for the ascent and descent phases, ensuring natural stability of the extreme aspect ratio wing, enabling low weight, robust and reliable flight controls,” says Davidson.

BATTERIES

Prismatic and AALTO are aiming for missions that will last between 180 and 200 days, which they expect to be possible quite soon as lithium-ion battery developers improve their cells. Today, says Davidson of Prismatic, “the best commercially available high-energy-density cells will permit mission durations of up to six months.” He predicts that “this will increase with time, driven by drone, automotive and consumer electronics demand.”

As for AALTO, Zephyr has achieved a 64-day mission so far, “and by next year we’ll hopefully be flying for 200 days — that’s quite a number,” says CEO Samer Halawi. After 200 days on station, a Zephyr will land to have its batteries replaced, since they will have been through the maximum number of charge/discharge cycles. Before that aircraft leaves its station, a fresh Zephyr will take its place. But there is a technical challenge for this long-endurance battery flight. The stratosphere, with air temperatures between minus 60 Celsius and minus 80 C, is a difficult place to recharge lithium-ion batteries, as each aircraft must regularly do as it flies.

“So one of the engineering challenges is thermally controlling the battery system in order to maintain cell temperatures at an optimum level,” says Davidson. “This is a result of the fact that there are relatively few molecules of air in the stratosphere to shed excess heat to, so overheating must be avoided.”

SOLAR ARRAYS

AALTO and Prismatic coat their wings with ultra-thin, high-efficiency solar cells from MicroLink Devices of Niles, Illinois, whose products are made for space and drone applications. The solar panels on satellites receive unfiltered sunlight, so they are designed to acquire different wavelengths than terrestrial solar panels that receive light that’s been filtered by the atmosphere. Because the light in the stratosphere is almost unfiltered, space-qualified solar cells are used for by Zephyr and PHASA-35.

“They are the best in class,” says AALTO’s Aubourg, referring to MicroLink’s products, “with efficiency of 30%.” To get weight down, MicroLink etches its silicon solar cell sheets to a thickness of just 50 micrometers in a process called epitaxial liftoff (ELO) allowing them to conform easily to a wing shape.

“The ‘light-weighted’ solar array is applied to the upper surface of the carbon fibre composite wing surface with electrical insulation between the two surfaces. Ensuring a low profile is key to minimising drag,” says Davidson of Prismatic.

AUTOPILOT

The “super-slim” wings of pseudo satellites, says Aubourg, are “super, super flexible” as well as ultralight. This flexibility can cause dangerous airframe resonances when turbulence strikes in the troposphere. So AALTO this year developed some new flight control laws for its automation software suite, which measures induced wing flexing in real time to apply correcting pitch, roll and/or yaw commands that cancel the effects of the wobble. Their trick? To pepper the airplane with accelerometers that let the avionics measure how the wing is flexing so that the automation software can compute correcting control inputs. In May, a Zephyr took off from the U.S. Army Proving Ground in Yuma, Arizona, and was purposefully flown into turbulence at 3,000 feet. The new control laws worked well.

“We were able to control the aircraft and keep it flying smoothly by taking advantage of the flexibility of the wings,” says Aubourg. “We are really, really proud of that.”

Prismatic CEO Bob Davidson agrees year-round launch and recovery is vital if PHASA operations are to begin in 2028. His team is also exploring advanced meteorology to get it: “The holy grail of HAPS is the tropospheric ascent and descent phase of the mission where the vehicle cannot fly through bad weather, nor is it fast enough to fly around it,” he says. “Developing advanced meteorological technology for weather measurement, and five-dimensional forecasting [that is, modeling latitude, longitude, time, altitude and uncertainty] is key to identification of candidate launch and recovery sites, often in remote locations, and it is a network of these that will provide us a viable solution.”

However, the former Zephyr designer Stevens believes that this barrier will not be an easy one to overcome with smart multidimensional forecasting alone. “HAPS aircraft fly so slowly that they are extremely vulnerable to gusts and turbulence during flight in the troposphere. The gusts and turbulence are really low level and often unforecastable prior to committing to a launch or recovery.”

The heart of the problem is the glacial speed of HAPS planes. “They have to fly so slow to keep their drag down and maintain a low enough power to cruise in the stratosphere throughout the night only on the energy stored in the batteries,” says Stevens.

What’s needed, he believes, is some fresh thinking: “The next generation of HAPS aircraft must be capable of expanding their operating envelopes to be less vulnerable to gusts and turbulence, and critically, without jeopardizing their cruise performance in the stratosphere.”

Voltitude may have a potential answer here — but it cannot reveal it yet, says Stevens. “We have been developing a range of new technologies to help make HAPS less vulnerable. The specifics are closely guarded, but we hope to be showcasing some of these new techniques next year in flight trials.”

So even with the enabling battery and solar cell technologies now deemed more than good enough, it seems that HAPS remain a work in progress. But they are edging ever closer to reality.

Editor-in-chief Ben Iannotta contributed to this report.

About Paul Marks

Paul is a London journalist focused on technology, cybersecurity, aviation and spaceflight. A regular contributor to the BBC, New Scientist and The Economist, his current interests include electric aviation and innovation in new space.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.