Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

The two companies that manufacture the vast majority of the world’s airliners, Airbus and Boeing, have diametrically opposed visions about the kind of aircraft and fuels that will be required if the air transport industry is to achieve net-zero carbon emissions by 2050. In our September issue, we took a close look at Airbus’ vision, “A Manhattan Project for the climate.” Now, Aaron Karp looks at Boeing’s thinking.

Joe Sutter, Boeing’s lead engineer for designing and developing the 747 in the 1960s, had some advice regarding new aircraft programs: “Take stock before charging out of the gate.”

Boeing appears to be heeding the late engineer’s suggestion — relayed in Sutter’s 2006 book “747” — as the company explores concepts for a next-generation commercial aircraft. Some 19 years after Boeing launched the 787 program, the manufacturer’s last clean-sheet airliner, it is taking its time studying potential new technologies for an aircraft that will not enter service until the mid-2030s at the earliest and, according to Boeing, needs to have a 25-30% fuel efficiency gain over currently operating aircraft such as the 737 MAX and 787.

That aircraft will also have to be environmentally sustainable, enabling airlines to meet the global industry’s 2050 net-zero emissions goal, which hangs over all considerations of a new airliner design.

“This is bigger than just a business decision,” Ryan Faucett, Boeing’s director of environmental sustainability, told me. “This is the future of our industry and relies on us really being ambitious” with a new design.

While Boeing has made no commitments about the shape of the new aircraft — CEO Dave Calhoun has preached patience to those who are curious — the company has offered clues. In particular, Boeing is eager to test the Transonic Truss-Braced Wing airframe configuration in conjunction with NASA on a modified MD-90 aircraft. This X-66A Sustainable Flight Demonstrator is targeted for flight tests starting in 2028 that are scheduled to last one year.

Boeing is “heavily invested” in testing the TTBW design, Calhoun said in July on the company’s second-quarter earnings call with analysts and reporters. “We like what it could potentially deliver to this market: a level of performance that the industry is used to seeing with brand new programs.”

He went on: “Suffice to say, we are intent on proving this technology. We are hopeful, and if it matures the way we think it will and that NASA frankly thinks it will, I do think it’ll see service.”

Brent Cobleigh, NASA’s X-66A project manager, told me by email that the TTBW design “by itself” could deliver a 10% fuel efficiency gain over “today’s best-in-class aircraft.” He said a TTBW aircraft would produce “less drag due to its longer, thinner wings” and “when combined with other advancements in propulsion systems, materials and systems architecture, the X-66 could result in up to 30% less fuel consumption.”

Cobleigh added: “TTBW also offers other advantages, including its high-wing design, which would allow for potentially larger-diameter, more efficient engines to be mounted underneath it.”

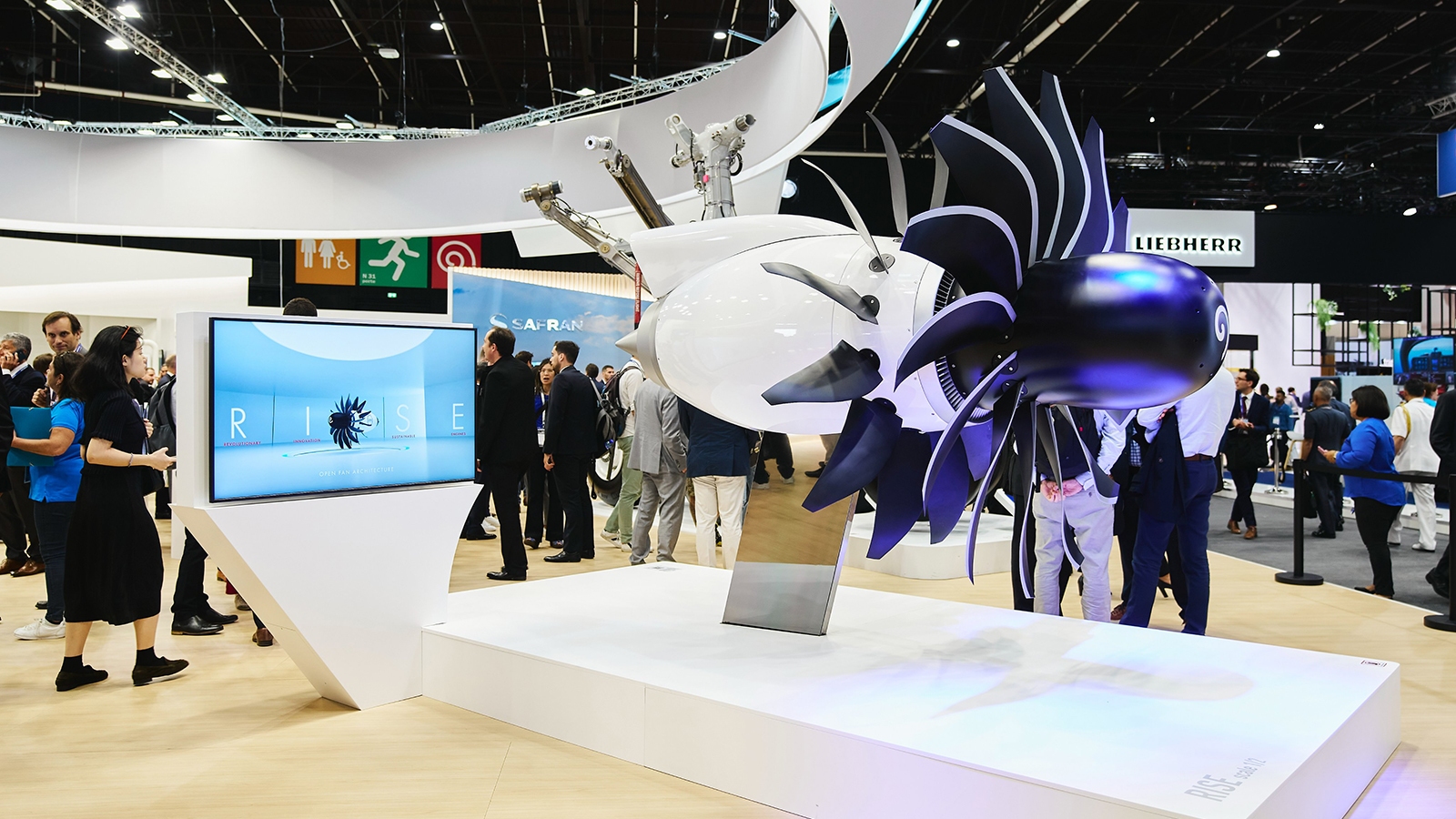

As for that propulsion, CFM International, the GE Aerospace/Safran Aircraft Engines joint venture, is researching an open rotor engine architecture to power potential commercial aircraft entering service in the 2030s. This design is part of CFM’s Revolutionary Innovation for Sustainable Engines program. The idea is to eliminate the case around the front fan of the engine, which GE Aerospace says would allow for a larger fan size and higher bypass ratio, meaning a larger portion of air flows around the engine core to generate thrust more efficiently. CFM envisions a 20% fuel efficiency gain from this open rotor design compared to current jet engines.

With its thinner wings set higher off the ground, a TTBW aircraft could accommodate such larger- diameter rotors. Pratt and Whitney is providing two of its geared turbofans for X-66A, but Calhoun has been noncommittal on an engine for Boeing’s next airliner.

“For me to pick and choose the power plants at this stage is probably not smart,” he said on the earnings call. “We can use existing power, but we would prefer frankly to have a bigger fan diameter ultimately, and maybe even open rotor someday.” But he added that “I don’t want to make choices too early.”

Current jet engine designs deliver about as much fuel efficiency as can be wrung from their enclosed cores and front fans, according to Pat Anderson, a professor of aerospace engineering at Embry-Riddle Aeronautical University and director of the Eagle Flight Research Center, Embry-Riddle’s aerospace research and design facility.

“Unfortunately, we’re in the incrementalism phase of improving jet engines,” he explains. “Jet engines are pretty amazing devices that have been around for 80 years, but we’re just tweaking them now for a possible 1% or 2% efficiency gain.”

He says the TTBW is “one of the more effective methods of reducing drag in an airplane that we have the ability to design.”

Regardless, whatever the design and engine type, Boeing has largely ruled out relying on the development of a new power source for this next-generation aircraft. Battery-electric and hydrogen-electric power, as promising as these technologies may be for smaller aircraft such as electric vertical takeoff and landing vehicles and even regional commercial aircraft, are unlikely to be viable for a 737- or 787-sized aircraft for the foreseeable future, according to Faucett.

“When it comes to hydrogen as a direct propulsion source, physics becomes a limiter,” he says. “Liquid hydrogen takes up a lot of space on an aircraft from a volume perspective. It’s also difficult to move around safely and requires a lot of infrastructure. We believe there’s a future in which you do have larger-sized hydrogen aircraft, but it’s just not likely in the 30-year window to get to net-zero.”

Faucett notes that “Most of the carbon emissions in commercial aviation, around 73%, come from flights over 1,000 nautical miles. It’s the longer routes, the larger aircraft where most of your emissions come from. Hydrogen is going to be a reality first on smaller aircraft, but it becomes very difficult to scale that into the larger aircraft where most of the emissions are coming from.”

Anderson, the Embry-Riddle professor, says hydrogen on a large aircraft must “be stored at high pressure or cryogenically, which goes to a weight problem.” He continues: “That’s problematic, and the other part is if you’re using a fuel cell, there’s actually cooling drag associated with it.”

Boeing earlier this year acquired electric aircraft designer Wisk, which is developing an autonomous air taxi, but Boeing’s interest in the startup is largely related to exploring autonomous flight, not battery-electric power.

Electrically charged batteries are “really, really terrific for road transport,” Faucett says. But with a large aircraft, “you run into real issues on the energy density contained in a battery compared to its weight.” Battery-electric airliners are “certainly not coming in the next 30 years.”

Anderson adds: “We would literally need Nobel Prize-winning battery chemistry development to see, anytime in the near future, a large-scale battery- electric airplane.”

So, Boeing believes a future aircraft will need to run on 100% sustainable aviation fuel — with potential feedstock sources, including nonedible plants, agricultural and forest waste, and municipal waste — and incorporate aerodynamic design changes that create significant fuel efficiency gains. But even if the company is able to achieve a 25-30% improvement in efficiency, SAF will be necessary to take care of most of the remainder of the carbon dioxide emissions produced by airliners, Faucett says.

“We’re very transparent about how big of a deal SAF is to the industry’s effort to decarbonize,” he explains. “Our industry is going to grow. Specifically regarding SAF, our industry lacks a lot of the options that other industries have for decarbonizing easily. So, we need alternative liquid fuels under almost any scenario to decarbonize in large volumes.”

Anderson says it is “nearly impossible to beat the storage of energy as a liquid from a weight standpoint. So, if we can make that liquid in a life-cycle that’s carbon neutral, then that meets our needs. With SAF, it means that however many billions of billions of dollars of airplanes we have out there, those airplanes really don’t have to change. Whereas the other two options of battery-electric or hydrogen require changes in the airframe, the engines, fundamentally everything.”

Boeing projects that, because SAF comes from renewable sources, it can reduce carbon contributions from air travel by 80% on a lifecycle basis versus standard jet fuel.

The manufacturer has committed to producing all aircraft from 2030 with capability to run on 100% SAF, and it is planning for any new aircraft to use only SAF.

Today, regulations in the U.S. and elsewhere limit SAF to 50% of an aircraft’s fuel for passenger flights, with airlines including United using 50% SAF blends on a small percentage of flights.

From a technical standpoint, Anderson says he sees “no barrier toward getting to 100%” SAF usage for passenger flights. “But if it’s something new in aviation, you’re obviously going to do a controlled entry into service. So, until you get lots of experience with it, it would be prudent to slowly increase the use of that fuel by mixing it with classic Jet A until you actually see if it affects engines long term or anything else in the system: any of the logistics, the fuel tanks, the tank cars, and so forth. I don’t think anybody’s seeing that, but obviously it would be prudent to go slow.”

Also, “there’s simply not enough” SAF being produced today to power the thousands of flights conducted every day, he says, “so mixing it with Jet A makes economic sense and also makes sense from a safety standpoint. As more of it comes online, that percentage will inevitably go up.”

United did operate an in-service flight between Chicago O’Hare and Washington National airports in 2021 with 100% SAF in one of the 737 MAX’s two CFM engines. The other engine had 100% Jet A fuel, so the 50% standard was met. The in-service demonstration was intended to show that operating an engine on 100% SAF is already technologically feasible. United uses a 50/50 SAF blend produced by Finland-based Neste Worldwide for flights departing from Amsterdam, San Francisco and London Heathrow airports. The fuel is sourced from used cooking oil and animal fat waste. In the future, the airline plans to purchase SAF from feedstocks that could include household trash, forest waste and algae.

United plans to use around 10 million gallons of SAF in 2023. But technological feasibility does not mean enough supply will be available for Boeing’s new aircraft to run on 100% SAF, even if standards change to allow for it. United has made a strong and very public push on SAF, investing in research and using the alternative fuel on a small number of in- service flights starting in 2016, but only 0.1% of its 2023 fuel consumption will come from SAF.

“It’s going to take the whole value chain,” including aircraft manufacturers, airlines, airports, governments and fuel suppliers to develop the infrastructure to produce the high levels of SAF that will be needed at airports worldwide, Faucett says. “That takes a collaboration between us and fuel producers, and then we also are working with governments. Policy is the big unlock here for scaling SAF.”

Boeing is encouraging governments to provide tax incentives and other inducements for producing and using SAF. “We don’t currently have a level playing field with road transport fuel incentives,” Faucett says.

Beyond fuels, Boeing is also testing 19 technologies this year on its latest ecoDemonstrator aircraft, a 777-200ER. Among them are wall panels in the cargo hold consisting of 40% recycled carbon fiber and 60% bio-based feedstock resin.

Some 230 technologies have been tested across nine ecoDemonstrators flown since 2012.

“We get to test the technologies on the ecoDemonstrator to see what works, what doesn’t work, see what makes sense for our production airplanes,” Faucett says.

Additionally, this year for the first time, the company is operating a series of “Explorer ecoDemonstrators.” In June, a 787-10 without passengers was flown from Seattle to Bangkok, Singapore and Tokyo to test “more efficient air traffic management” in conjunction with air traffic control providers.

The flights demonstrated that “if you can manage that airspace better, you can actually gain efficiency,” Faucett says. Boeing believes such improved air traffic management can improve fuel efficiency by up to 10%.

With demanding net-zero goals that need to be met, the company is indeed looking for every efficiency gain it can find, so a potential new aircraft can operate in an environmentally sustainable way well into the second half of this century.

The 747 program — initially believed to be a temporary solution for long-haul air travel before fleets of supersonic jets were expected to take over — lasted for more than 50 years and produced more than 1,500 aircraft. To achieve a similar lifespan and success for its next airliner, Boeing is aiming for a sustainable solution that will have staying power in a decarbonized world.

About Aaron Karp

Aaron is a contributing editor to the Aviation Week Network and has covered the aviation business for 20 years. He was previously managing editor of Air Cargo World and editor-in-chief of Aviation Daily.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.