Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

Flying a 3D printer on a satellite could lay the groundwork for the in-space manufacturing of large hardware that otherwise would not survive launch nor fit inside a rocket’s fairing. Adam Hadhazy walks through the mission and its motivations.

The paradigm that’s held for nearly everything we’ve ever put into space, going back six-plus decades, is “make it here, launch it there.” Although plenty successful, this paradigm has also proven to be stunningly inefficient. A satellite must be overdesigned and overmanufactured to withstand the heavy G-forces, violent shaking and sonic assault of launch and ascent, despite the fact that the satellite will spend its entire operational life in smoothly soundless weightlessness. Then there is the tyranny of the fairing. Because engineers can only make rocket nose cones so big, payload sizes are severely constrained.

NASA mission planners hope to flip this Space-Age-old paradigm on its head with the OSAM-2 mission, short for On-orbit Servicing, Assembly, and Manufacturing and formerly known as Archinaut. Plans call for a small spacecraft equipped with a 3D printer to additively manufacture a plastic beam, or boom, that will unfurl a simulated solar sheet into place. A robotic arm will swivel the printer around 180 degrees to print a second test boom.

If satellites can be programmed to sprout components in this manner, then an even bolder vision could lie ahead. Perhaps spacecraft parts could be manufactured in the vacuum of space from celestial raw materials and be assembled by robots into communications satellites, space station modules, or astronomical observatories. The result would be a vibrant economy in the final frontier, and one largely untethered from an Earth-to-orbit supply chain.

The $94 million OSAM-2 mission would be just the start, however. Still to be proven would be the ability to unfurl an actual solar sheet in space, perhaps even additively manufacture it and assemble multiple such sheets into vast, electricity-generating arrays. Today’s arrays consist of solid panels that must be folded up inside fairings and subjected to the brutalities of launch, which limits their size and design. Solar arrays are just one example of the changes to come. Engineers envision giant radar support elements and other structures. “What you want to manufacture is really limitless,” says Tom Campbell, president of Made In Space, the lead developer for the OSAM-2 mission and a subsidiary of Florida-based space conglomerate Redwire.

Beyond OSAM-2, other researchers are devising robotic methods of refueling spacecraft and replacing worn or faulty parts. Among them are the members of NASA’s OSAM-1 team, an in-house effort at NASA’s Goddard Space Flight Center in Maryland in collaboration with Colorado-based Maxar Technologies. They plan to launch a “servicer” satellite in 2025 that will grasp, refuel and adjust the orbit of a guinea pig, so to speak, in the form of the 22-year-old Landsat 7 Earth imaging satellite operated by the U.S. Geological Survey.

“If you can do those three key elements — on-orbit servicing, assembly and manufacturing — you could open a design space for some really awesome things,” says Larry Huebner, the NASA technical lead for OSAM-2.

While NASA has no expectations that OSAM-style capabilities will be ready in time to affect the agency’s long-shot plan to return to the moon in 2024, it could factor into future launches under the Artemis program. “Artemis is about more than getting back to the moon; it’s about sustained human presence on the moon and the ultimate goal of going to Mars,” says Huebner.

Transcending the barriers of fitting in fairings and surviving launch loads by erecting factories in space could be the path forward to a sustained human presence.

“When you combine the capabilities of autonomous, in-space additive manufacturing with robotic assembly techniques, we see the possibilities for beginning to build a true infrastructure supporting human exploration, science missions, and eventually the economic development of space,” says Mary Lynne Dittmar, president and CEO of Dittmar Associates Inc., and who formerly managed flight operations for Boeing’s International Space Station program.

3D printing on high

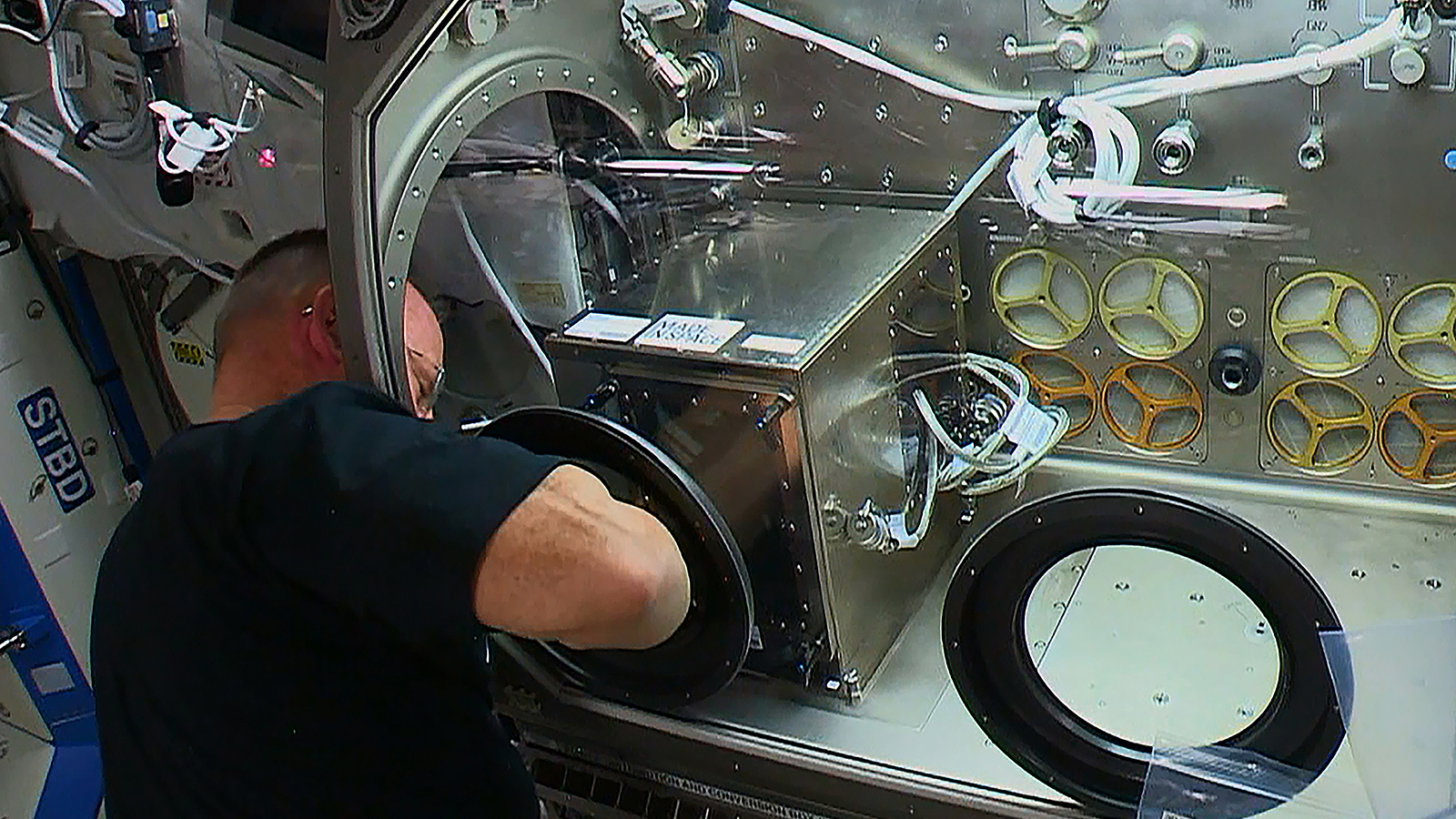

When NASA awarded Made In Space the initial proof-of-concept contract in 2016, the company and NASA had already accumulated three years of lessons about 3D printing in space, albeit in the solar-protected, pressurized volume of the International Space Station’s U.S. Destiny Lab with a flight engineer tending to it.

That engineer, former NASA astronaut Barry “Butch” Wilmore, recalls unloading the 3D printer from a Dragon capsule and setting up the apparatus. In the first print jobs, the extruded material would not adhere to surfaces. “We had some strange-looking objects that came out of the printer,” says Wilmore, laughing. Via live camera feeds, Wilmore worked as “the eyes and ears,” he says, for the Made In Space engineers on the ground as they sorted out the issue. Changing the angle of the pan where the melted plastic deposited and moving the pan closer to the nozzle troubleshot the problem, recalls Wilmore.

A design adjustment was also needed before the printer ever left the ground. Made In Space chose a well-established process on Earth, the fused filament fabrication technique, also known as fused deposition modeling. A spool feeds threads of plastic through a heated nozzle that melts the plastic and deposits the material one thin layer at a time, over and over, on a flat surface or starting block. The process continues until the printer achieves the designed size and shape of the intended object. Engineers needed to transfer heat away from the print head and away from the extruded, printed plastic so it would properly harden. In Earthly conditions, two modes of heat transfer — conduction and convection — readily accomplish these tasks. Conduction primarily involves heat transferring through solids, such as the pan that the plastic prints onto, but also through the air as gas molecules come into contact with heated surfaces and absorb heat. At that point, the second mode of heat transfer, convection, whisks away warmed molecules and brings in fresh ones that soak up heat and carry it away.

Convection requires fluid flow, something that occurs naturally on Earth whether the fluid is a liquid or gas. Such flow does not happen naturally on the station, because the station and everything inside it, including the air, are in free fall due to gravity, giving the illusion of weightlessness. A parcel of denser cool air therefore does not sink naturally into the less dense warm air, as it does on Earth, triggering circulation. Left to its own devices, the station’s internal atmosphere is accordingly stagnant, says Paul Shestople, Made In Space’s project manager for OSAM-2.

Knowing this, the Made In Space engineers instead induced artificial convection with a fan that blew air around the station’s 3D printer. “Without gravity or a fan, the hot molecules just sit there [on a hot surface],” says Shestople. “You can force convection with a fan. That’s what we do on the ISS, which has atmosphere but microgravity.”

That solution, however, won’t do in the airlessness of space.

Truly “made in space”

Shestople and the Made In Space engineers therefore devised a new, space-tailored 3D printer for OSAM-2 dubbed ESAMM, for Extended Structure Additive Manufacturing Machine, the device that the robotic arm will swivel. “ESAMM is made for building in zero-G and very low pressure, very low atmosphere, and through a wide variety of temperature swings,” says Shestople.

Those temperature swings further complicate the dynamics of desirable heat transfer. Although interstellar space sits only a smidge above absolute zero at minus 270 degrees Celsius (minus 455 degrees Fahrenheit), thankfully, the Earth is close enough to a star and radiates enough heat that the mercury doesn’t plummet that low. Instead, engineers must deal with the wild differences between “night,” when an orbiting spacecraft passes through Earth’s shadow, and “day,” when the spacecraft is hit with direct sunlight. In shadow, temperatures can plunge to ballpark minus 100 degrees Celsius (minus 148 degrees Fahrenheit), while in direct sunlight, temperatures spike to around 100 degrees Celsius (212 degrees Fahrenheit).

In such an airless and extreme thermal environment, versus an air-filled room or space station module, engineers have to exert exceptional control over the various paths of heat transfer to print accurately. “The main difference, as far as how you do that, is paying attention to those heat paths,” says Shestople. “You need to make sure that the area where the printer is printing is maintained at a good temperature profile, while at the same time making sure you can take heat and transfer it away from that area so it doesn’t get red hot.”

Radiation, a third mode of heat transfer conveyed by electromagnetic waves (that is, light, typically infrared), does some, but far from all of the necessary heat transfer for OSAM-2’s print head. “The print head is inside the satellite and is pretty small,” says Shestople. “It doesn’t have sufficient radiative surface to get rid of all the heat it generates.” The engineers therefore had to find a way to pull more heat from the print head to cooler areas within OSAM-2, and they did, courtesy of the metal copper, an excellent heat conductor. “Since we can’t rely on convection, the heat has to be conducted away through the printer surface and printer elements,” says Shestople. “Unfortunately, there isn’t enough conductive material to transport enough heat away, so we augment it with copper straps.” The overall design shuttles this heat to external surfaces of the spacecraft to radiate away into space — the eventual fate of all the heat generated on OSAM-2, seeing as there is nowhere else for it to go.

For proprietary reasons, Made In Space won’t go into further details. Nor will the company reveal the polymer OSAM-2 will use, except to say it must resist degradation by ultraviolet light, which is a challenge outside the shelter of an ISS module. Made In Space has, however, tried the aerospace-grade polymer, PEI/PC, or polyetherimide/polycarbonate aboard the space station and in ground tests of ESAMM, suggesting this may be the polymer of choice.

Those tests, performed in 2017, were part of the $20 million proof phase to demonstrate that ESAMM could churn out beams in simulated space conditions. Based on that success, NASA’s Space Technology Mission Directorate then awarded Made In Space a $73.7 million contract in 2019 to carry out the mission, provided the company covered additional expenditures amounting to at least 25% of the total mission cost. The contract brought the latest version of ESAMM through testing in late 2020 at a Jacksonville hangar, confirming the printer can operate in weightlessness. Testing ESAMM on a free-falling airplane (in popular parlance, a vomit comet) was never feasible, given the too-short-for-printing, half-minute windows of micro-G such planes provide. Instead, through a gravitational sleight of hand, engineers effectively mimicked printing in weightlessness. The engineers pointed the printer up in order to print a beam vertically, attached a wire to the top of the forming beam, and then ran the wire through a pully to a counterweight. As the beam increased in length and mass, the team added mass to the counterweight, thus effectively counteracting the mass of the beam.

The development of the rest of OSAM-2 has likewise proceeded in recent months. In December small-satellite maker Blue Canyon Technologies of Colorado provided the spacecraft’s bus to another OSAM-2 subcontractor, Northrop Grumman, which will further assemble and install OSAM-2’s elements. One of those will be the robotic arm, provided by Motiv Space Systems of California. The engineering design unit — a rough-draft version of the arm, made of less expensive materials and not fully vetted for flight — was readied earlier this year.

Cosmic print shop

After its several years of development, OSAM-2 is now up for a critical design review midyear and is slated for launch no sooner than 2023. Should OSAM-2 proceed into full fabrication and fly, the satellite would enter a low-Earth orbit and ESAMM would begin its first print job, a beam 10 meters long extending out into space. A unique situation with 3D printing in the vastness and weightlessness of space, Made In Space’s Campbell points out, is that there is no limited or defined printer volume, as is the norm for 2D and 3D printers. Instead, so long as ESAMM has raw material fed into it, it can print beams to extreme lengths in marked defiance of rocket fairing-imposed limits.

As this beam grows, it will pull the film-like simulated sheet made of Mylar, Kapton and other materials from a compartment at the base of the beam until it stretches the length of the beam. The film will be about the same thickness and flexibility as an actual sheet of flexible solar material. Initially, Made In Space was going to unfurl an actual solar sheet, but this plan was scaled back to a simluated one.

The benefits of a broad shift to flexible solar materials would be considerable, given the significantly greater surface area that flexible arrays could provide compared to the standard, fairing-folded arrays. In the specific case of the relatively small, refrigerator-sized OSAM-2 spacecraft, the proposed solar sheet would have generated five times as much power as a traditionally sized array.

After the first beam prints, the robotic arm will flip ESAMM around in order to print a beam out of the other side of the spacecraft. The fabricating of this second beam, measuring 6 meters, would demonstrate the ability to handle multiple jobs, while hinting at the sort of on-orbit object manufacturing complexity that could be achieved once coupled with robotic arm-enabled assembly.

As a bonus, printing these kinds of long beams in weightless space requires less material than if the same beams were made under gravity’s relentless pull, says Shestople. That weight forces one to include thicker, load-supporting elements. Proving out just how much less material one could skate by with would be the province of a future mission. For now, as the first mission of its kind, engineers intend to load OSAM-2 with about 50 kilograms of printer stock material, enough to print beams matching those already produced and tested at Earth-level gravity. “There’s the saying ‘test like you fly, fly like you test,’” says Shestople.

An enhanced future in space

Although at this point, the additive manufacturing process would be a slow one — with the entire OSAM-2 demonstration expected to take several weeks, including some stoppage time built in for assessment — the overall time and cost savings of this approach to building space hardware should be significant, Shestople says.

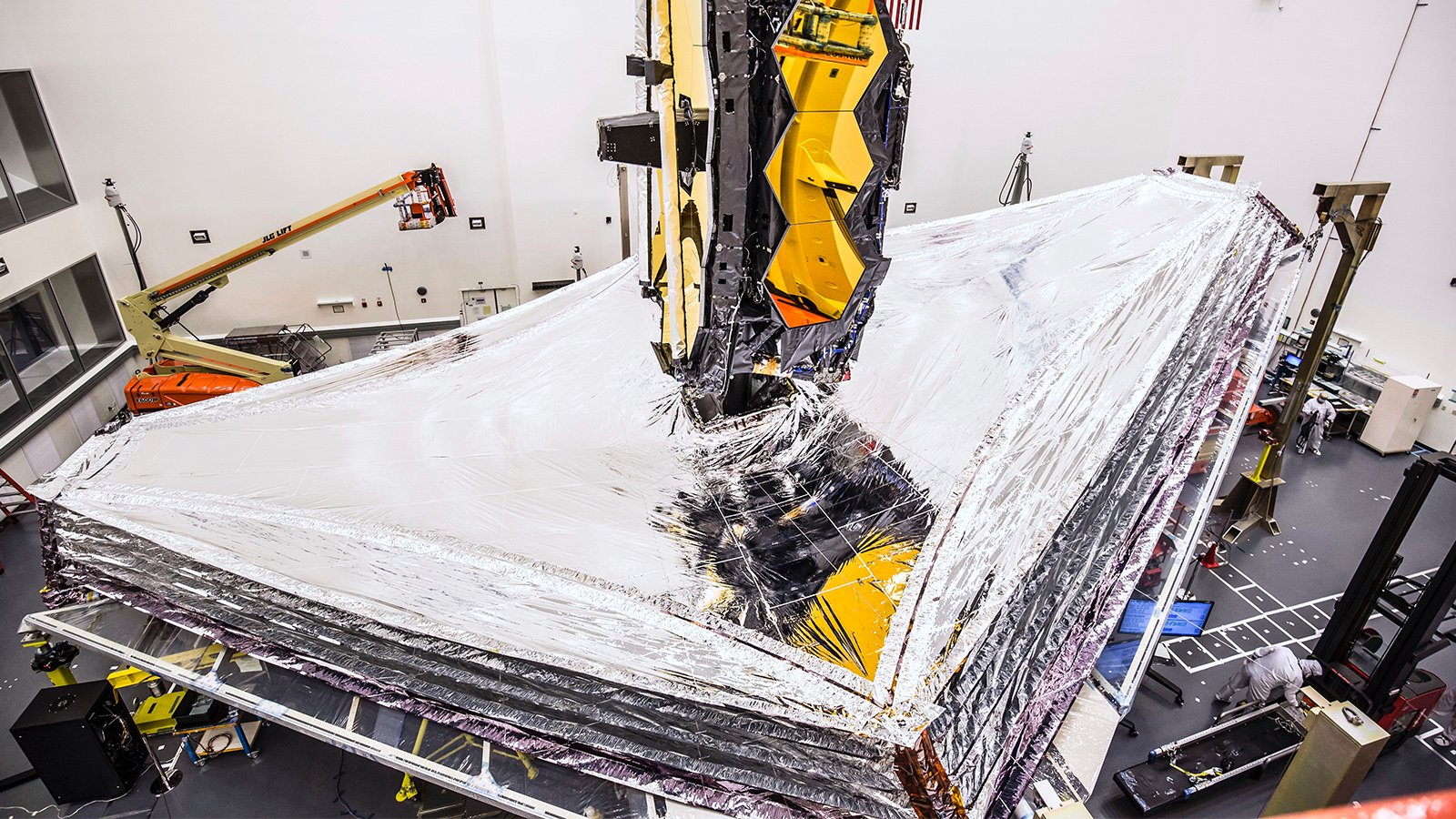

He points to the James Webb Space Telescope, the NASA flagship astrophysics mission, as a prime example. Wildly overbudget and behind schedule, its original 2007 launch and $500 million price tag have since slipped to late 2021 and swelled to $9.6 billion including cost of operations. A major reason: In order to stay extremely cold for conducting infrared observations, Webb requires a tennis court-sized sunshield. That piece of hardware is far too big to fit in any of today’s fairings.

Engineers have thus had to devise means of folding up the sunshield like an umbrella to squeeze within an Ariane 5 rocket’s standard 5-meter-diameter fairing. The shield has to then unfold and stretch taut in space, a process that involves 139 actuators, eight motors and thousands of other components. Nightmarishly, engineers have had to test and retest this mechanism in terrestrial gravitic conditions, completely unlike the actual scenario in space, as well as ensure that all components can endure the strain of launch and ascent.

“With [OSAM-2] technology, you’re not designing these super-complicated mechanisms like on JWST, you’re building structure on-orbit and assembling it there,” says Charlie Adams, the NASA mission manager for OSAM-2. “That’s an advantage.”

This liberation from Earth’s gravity well could jump-start space exploration and eventually empower a genuinely space-based economy, OSAM-2’s backers say.

“To carry out human missions, we need to put a basic infrastructure in place — power, water, communications — oxygen, since we’re in space — transportation, et cetera,” says Dittmar. She calls OSAM-2 a “significant step” toward proving that those power needs, which are the linchpin for everything else, can be met.

“If we want men and women to live and work in space, there’s got to be an economy there,” adds Campbell. “And to have an economy, you’ve got to have manufacturing.”

About Adam Hadhazy

Adam writes about astrophysics and technology. His work has appeared in Discover and New Scientist magazines.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.