FAA advances testing for airworthiness of electric aircraft battery

By Paul Brinkmann|January 5, 2023

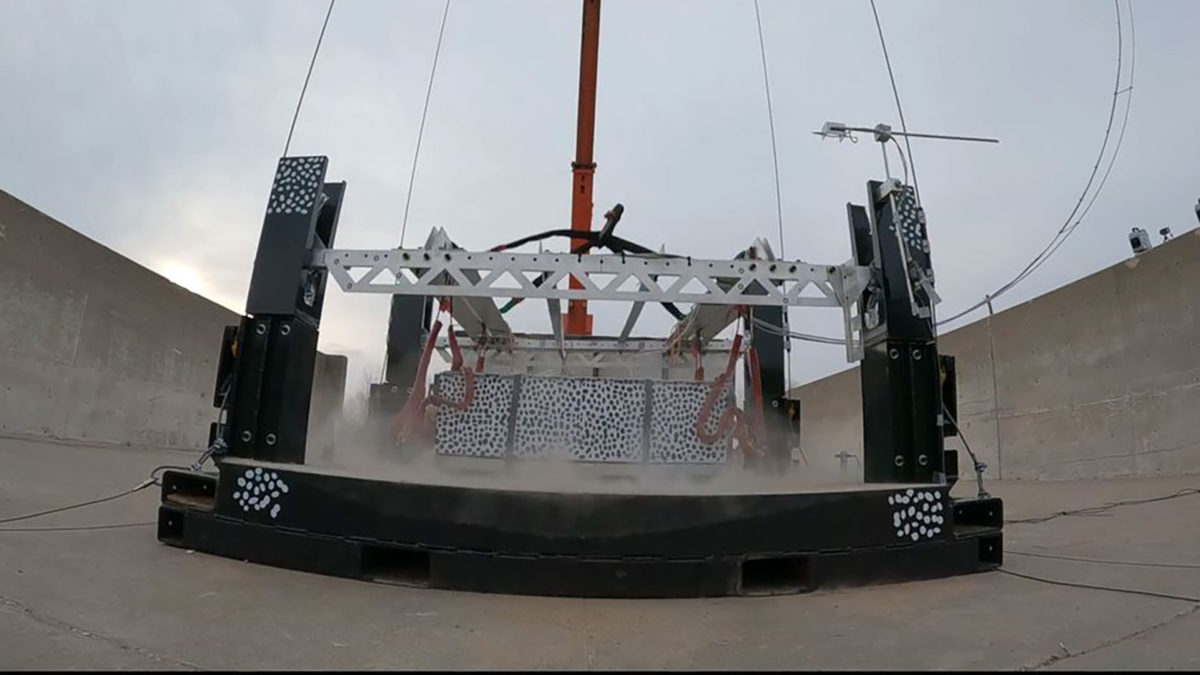

Electric aircraft battery survives 50-foot drop test

On a gloomy winter day in Kansas last month, researchers working for FAA gathered in an open field and released a lithium-ion battery from a crane, videotaping it as it fell onto a flat concrete surface 15 meters below to mimic the force of a crash or hard landing.

After the Dec. 7 drop test, researchers disassembled the battery and inspected all the cells. “Everything seems to look pretty good,” says Gerardo Olivares, the director of crash dynamics at Wichita State University’s National Institute for Aviation Research, home to the FAA Center of Excellence for Composites and Advanced Materials.

The FAA facility is run under contract by the institute, where Olivares oversaw the battery drop test.

Vermont-based aircraft developer Beta Technologies provided NIAR with the battery and details on its materials and specifications. The institute has run virtual simulations using that information. Beta is developing the Alia electric vertical takeoff and landing aircraft, or eVTOL, and has completed thousands of hours of piloted flights with test versions.

The drop test performed in December was just one test in the FAA program run by NIAR to develop testing standards for lithium-ion batteries, and was likely the first of many, Olivares said.

“I think it’s good for the industry because we’ve had some concerns about lithium-ion batteries during an impact, whether they would rupture or catch fire,” Olivares said. “I think it’s very good that one of the industry’s OEMs [original equipment manufacturers] was able to pass one of these tests.”

The “50-foot drop” was the same as required by FAA to demonstrate airworthiness of a standard fuel tank when dropped full of fuel. Similarly, the battery was nearly fully charged during the test, Olivares said.

He said FAA officials couldn’t be on site for the test itself but monitored it remotely via live video.

“We are still evaluating data from cameras, high-speed video and sensors on all the cells and throughout the frame and protective structure,” Olivares said.

FAA’s equivalent in Europe, the European Union Aviation Safety Agency, has adopted the 50-foot drop test as a formal part of its certification for battery-powered aircraft, but FAA is continuing to evaluate how it wants to conduct such physical tests.

“The simulations were great, but one thing we could not understand with simulations is the electrical and thermal behavior, like if there were shorts internally that could cause thermal runaway and eventual explosion. We couldn’t model for that without more data,” Olivares said.

He added: “We’re going to try to convince more manufacturers to contribute their batteries for testing.”

Another point of the drop test was to evaluate risk of high-voltage discharge to the surrounding eVTOL structure, occupants or first response personnel. Firefighters were on the scene for the test but were not needed as no fire threat emerged, Olivares said.

Beta believed its batteries were ready for such testing and the company wanted to acquire more data on its performance, Sean Donovan, a mechanical engineer and member of Beta’s battery team, told me in an email.

“This was a chance to really put our work to the test. It was also an important opportunity to help set the foundation for safety and standards within the industry,” Donovan said, adding that the test “proves that batteries are safe and behave how we predict they will.”

Get the latest news about advanced air mobility delivered to your inbox every two weeks.