Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.

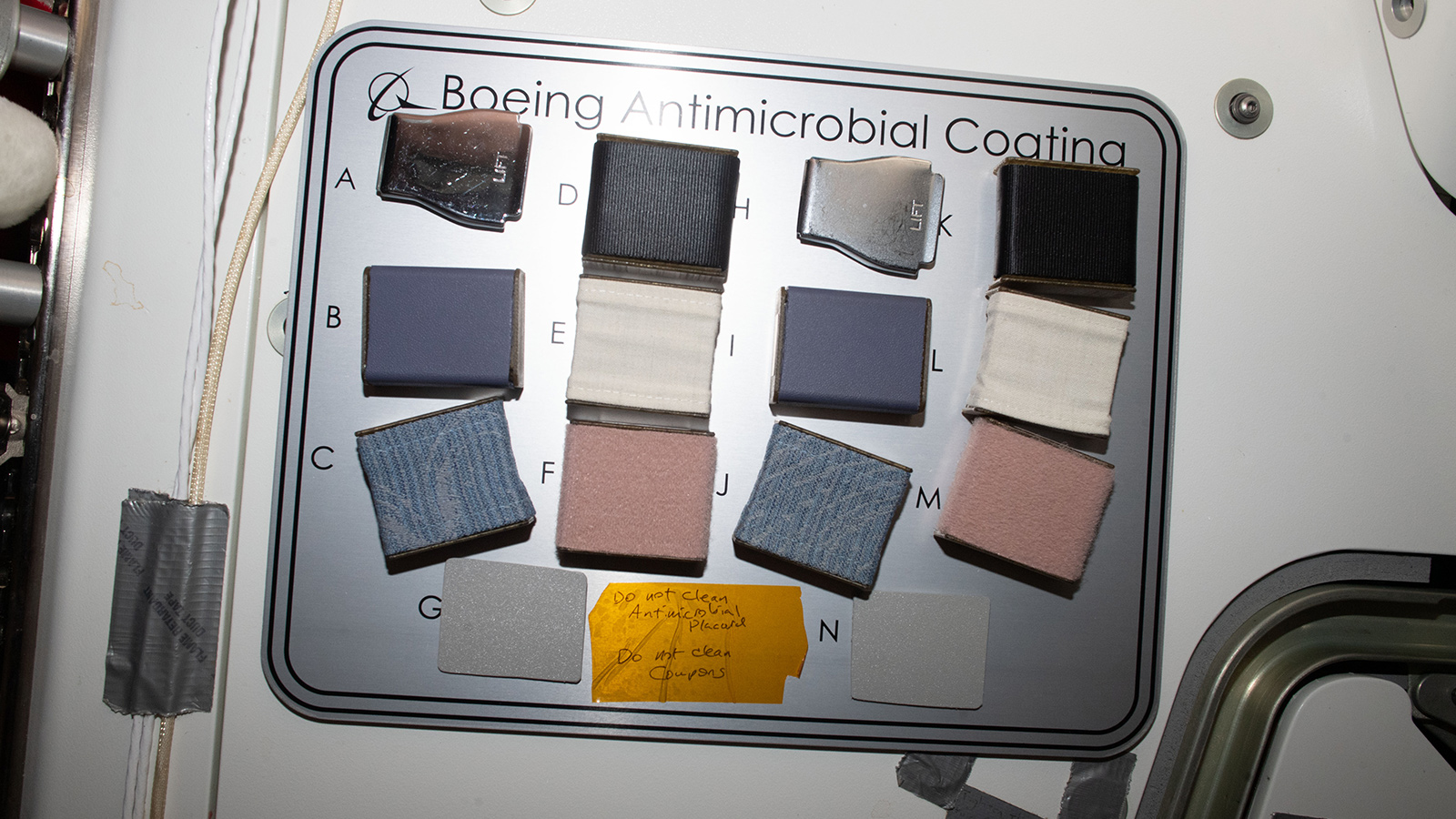

Every few days, the NASA astronauts aboard the International Space Station float through the U.S. Harmony module and brush their fingertips across a swatch of woven aircraft seat cloth, a seat buckle and other samples coated with a clear, proprietary polymer.

It’s all part of a Boeing and University of Queensland experiment set to run through July to test the ability of this polymer to tear apart microbes, meaning viruses and bacteria, left by an airline passenger or a spacecraft crew member bound for Mars. Among the patches on the wall-mounted plaque are padding and other materials one would expect in the interior of a spacecraft. Any microbe is trapped by charged particles in the polymer, and the heat from the astronaut’s fingertips changes the shape of the polymer “and tears the microbe apart to rupture it,” says Jason Armstrong, head of the team of Boeing researchers at the Australian branch of the company’s Research & Technology division.

The researchers prepared two identical sets of patches, one of which was sprayed with the polymer coating before it was launched to the station in December aboard a SpaceX Dragon 2 capsule. Once the patches are brought home, Boeing researchers at the company’s Houston labs will swab both sets and look under a microscope to compare the number of intact microbes. The polymer-coated patches should show a 3-log, or thousand times, reduction in the number of intact microbes.

The researchers began developing the coating four years ago for future crewed missions to Mars — the goal being to protect astronauts from unknown pathogens while also preventing naturally occurring microbes on human skin from eroding spacecraft surfaces over the course of long-duration missions. But after the onset of the pandemic, they decided to modify the polymer to bind and destroy the SARS-CoV-2 virus that causes covid-19.

Early laboratory tests in Australia in which patches were coated with the polymer and then swabbed with samples of influenza viruses and salmonella bacteria showed “really promising” results, Armstrong says. The researchers decided to apply through the United States ISS National Lab process, and they won a coveted experiment spot.

Beyond human spaceflight and passenger air travel, Armstrong says the polymer coating could also be adapted for use in hospitals or other applications. Just dissolve the polymer in water and it could be “sprayed over anything that’s already been manufactured, or it could be put into a manufacturing assembly line and sprayed there and then components are assembled somewhere else.”

As for space applications, Armstrong says it’s likely the polymer coating could win regulatory approval in time for early crewed missions under NASA’s Artemis program, which plans to land two astronauts on the lunar surface in 2024.

About cat hofacker

Cat helps guide our coverage and keeps production of the print magazine on schedule. She became associate editor in 2021 after two years as our staff reporter. Cat joined us in 2019 after covering the 2018 congressional midterm elections as an intern for USA Today.

Related Posts

Stay Up to Date

Submit your email address to receive the latest industry and Aerospace America news.