Hydrogen: coming to an aircraft near you

By Karen Kwon|July/August 2022

Hydrogen-powered aircraft could prove to be the best way for the air travel industry to meet its bold commitment to net-zero carbon emissions by 2050. For that to happen, hydrogen must be stored safely on these next-generation aircraft, and the question is the best way to do it. Karen Kwon tells the story.

Most executives like to use specification sheets to illustrate the benefits of new products. Paul Gloyer likes to show a photograph. In it, two kindergarten-aged children clutch the ends of a black cylindrical tank at least 10 times their size, lifting it off the ground with ease.

“This is a really good example of highlighting how light the tank is,” says Gloyer, president of Gloyer-Taylor Laboratories, or GTL, a Tennessee aerospace research and development company. The girls in the photo are children of a company employee.

Gloyer’s composite tanks are among those in the works by a handful of companies vying against metallic versions as the best method of storing molecular hydrogen as an aviation fuel. Researchers know they must get that answer right if hydrogen-powered aircraft are to lead the way in decarbonizing air travel. At stake could be whether the air travel industry meets its commitment of achieving net-zero carbon emissions by 2050, a target set in 2021 by the International Air Transport Association, an airline membership organization.

Molecular hydrogen is an attractive option because, whether combined with oxygen in a fuel cell to create electricity to power motors or combusted in liquid or gaseous form, the main byproduct is water vapor. While both water vapor and carbon dioxide contribute to atmospheric warming by trapping heat radiating from the Earth, water molecules remain in the atmosphere a handful of days before dissipating or falling to Earth as precipitation instead of lingering for decades as carbon dioxide molecules do. Not only that, hydrogen molecules unleash three times the amount of energy of traditional jet fuel by mass.

But that advantage is offset by a volume conundrum: It would take 3,000 liters of unpressurized, ambient-temperature gaseous hydrogen to release the same amount of energy as a liter of conventional jet fuel, according to Airbus, which is studying aluminum fuel tanks for a future hydrogen passenger airliner. This volume could be reduced by pressurizing hydrogen and storing it at cryogenic temperatures to keep it in a liquid state. But even then, it would take four liters of hydrogen to deliver the punch of a liter of jet fuel. The fuel tanks would still be too large to fit inside an airliner’s wings and center section, which is the common strategy today.

Success will largely depend on designing and building lightweight tanks that can carry large amounts of liquid hydrogen and meet the industry’s lofty standards for passenger safety. Airbus and other companies pursuing aluminum and other metallic designs are betting that these widely used materials offer the quickest route to bringing hydrogen-powered aircraft to market, while Gloyer is among those who believe composite tanks are the best way to meet the weight goal.

Weighing the challenge

Just the basic premise of a hydrogen fuel tank makes the extent of the challenge apparent. Packing the molecules together in liquid form and keeping them that way requires extremely low temperatures — at least minus 253 degrees Celsius. This in turn calls for a multilayer tank that needs, for long-distance flights, an active cooling system that basically works like a refrigerator by circulating cryogenic fluid such as helium gas through high and low pressures.

All these extra parts, of course, would add more weight to a design and reduce the amount of fuel that can be carried.

“Looking at tank mass, there’s been discussion of composite tanks versus metallic tanks,” says Wesley Johnson, a NASA engineer whose focus is on cryogenic technologies. In the past, NASA has used cryogenic tanks made from composites for various spacecraft, “but there’s different requirements on the airplane side that may drive how you design and develop those.” Hydrogen tanks for aviation must endure multiple uses, for example.

Gloyer’s GTL company sees its carbon fiber composite design as a way to keep the tanks light enough for aircraft of all sizes, from turboprop planes and jets that conduct regional flights to the large passenger airliners needed for long-haul travel. Located near the University of Tennessee Space Institute, GTL has until recently mostly concentrated on building space hardware, especially on reducing the propellant tank mass for launch vehicles. Then, “a few years back, we had some customers in the aviation industry come to us and say, ‘Your technology that works for cryogenic propellants for rockets, can that work for hydrogen for airplanes?’ And we were like, ‘It should,’” Gloyer says.

That pivot has worked in the company’s favor. GTL announced in March that it had built a 2.4-meter-long cryogenic tank — the same one that the two girls were lifting in the photo. Weighing in at 12 kilograms when empty, the tank weighs a quarter of what the other state-of-the-art aerospace cryogenic tanks weigh, according to Gloyer. And to keep the inside temperature of the tank from rising during flight — which would result in boiling, turning the liquid hydrogen into gas — the tank is double-walled with a vacuum in between the layers to reduce heat transfer from the tank’s exterior.

For the insulation, many manufacturers apply spray-on foam insulation. “All of that gets really heavy,” Gloyer says. “The best way to do it is with a vacuum-insulated system, like a Yeti cup,” which also relies on a double-walled design to minimize heat transfer.

Based on his review of published specifications from other companies, U.S. Department of Energy reports and what GTL’s customers have shared about the performance of competitors’ tanks, Gloyer says that typically, only 5% to 7% of the total weight of a tank comes from the fuel itself. The rest is due to the tank structure, though some are now reporting 10% to 12% thanks to the industry-wide push for higher hydrogen percentages. But the hydrogen fraction is much higher for GTL’s new tank: 60% to 70%.

“So what that ends up meaning is that for the same 100 kilograms with our tech versus somebody else’s tech, you can carry 10 times as much hydrogen fuel as you could with current technology,” Gloyer says. “That’s the game changer.”

GTL in March announced it would sell its tanks alongside fuel cell stacks from HyPoint of California to aircraft manufacturers. According to HyPoint’s internal analysis, pairing GTL’s 150-kilogram tank with HyPoint’s fuel cell stacks would almost triple the range of a 50-seat De Havilland Canada Dash 8 Q300 to 4,500 kilometers, compared to the 1,500-kilometer-range the same plane would have with its two turboprop engines burning conventional jet fuel.

Separately, Gloyer says GTL is in discussions with several customers to conduct flight demonstrations with the new tank in vehicles including airships, helicopters and airplanes. The company is also planning an in-house flight demonstration of a liquid-hydrogen-powered hovering drone in 2023.

One of the goals of these demonstrations is showing off the increased range that is possible with GTL’s design, Gloyer says. “There’s a lot of people doing demos right now where they put the hydrogen in vehicles, they basically take off, fly for a few minutes, and then they land because they’re out of fuel. The hard part is having enough fuel to go far.”

And the lighter the tank, the more fuel the aircraft could carry, which would reduce the operating cost per passenger for airlines. Gloyer says that according to his calculations, the GTL tank would make it cheaper to operate regional jets and long-haul aircraft on liquid hydrogen than conventional jet fuel.

“So you end up with a new paradigm” where the switch to hydrogen would be driven by financial incentives in addition to the desire to reduce carbon emissions, he says. “You’ll be stupid not to transition to hydrogen.”

Betting on metal

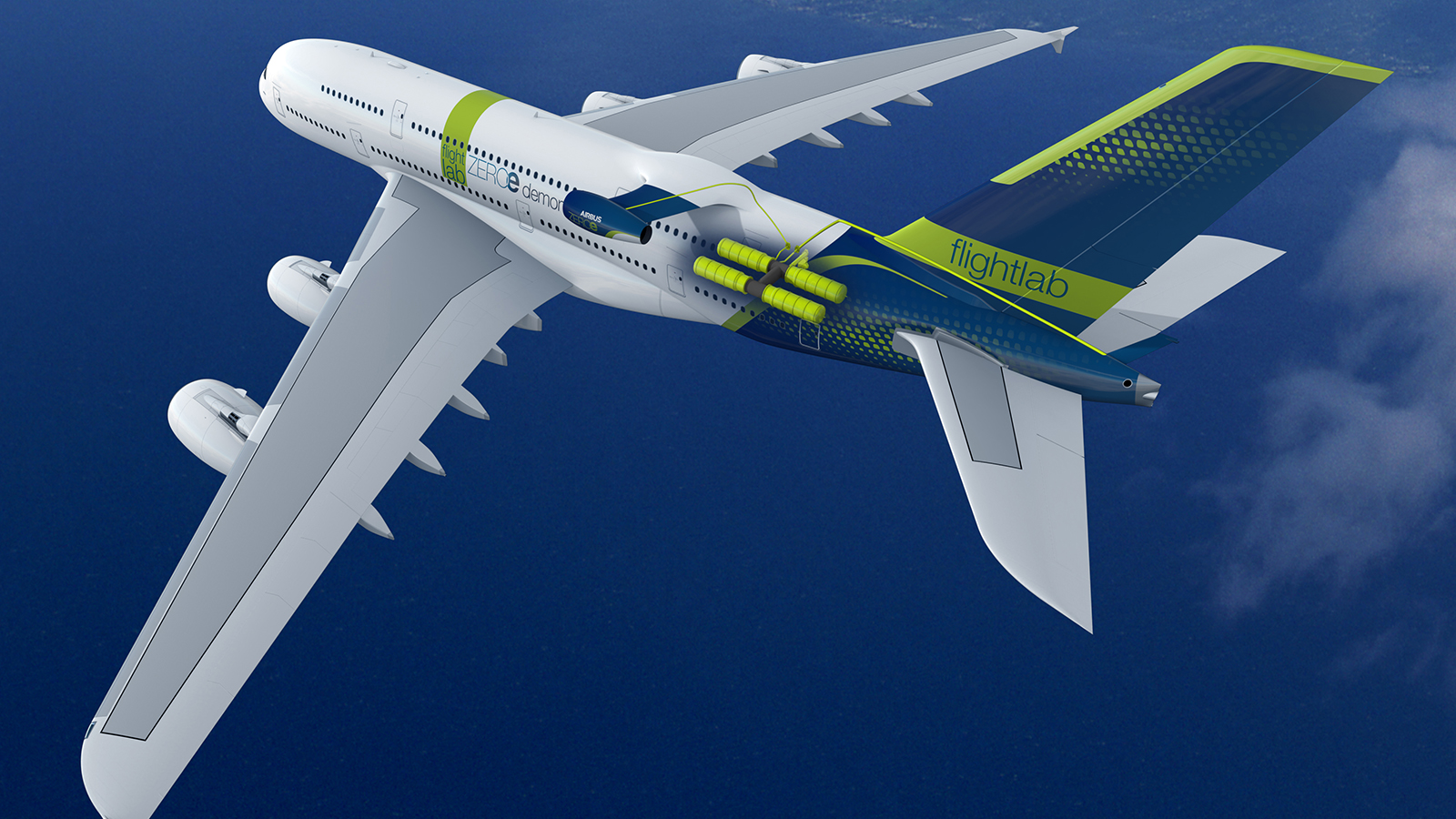

Despite the potential for lighter-weight designs that composites afford, Airbus is one of the companies sticking with metallic tanks for the time being. As part of its ZEROe initiative to design and build a hydrogen passenger airliner that would begin service in 2035, the company is developing cryogenic aluminum tanks at its various Zero-Emission Development Centers throughout Europe.

“Maybe in the future, we will explore CFRP [carbon-fiber-reinforced polymers]-like tanks,” says Mathias Andriamisaina, head of Airbus’ ZEROe demonstrators. “But for the moment, we are looking at metallic.”

He says that the weight of the tanks could be reduced by getting rid of the active cooling system and changing the type of insulation inside the tank, to name a couple strategies. Plans call for installing four of these aluminum tanks on an A380 test aircraft Airbus is modifying into the ZEROe demonstrator. In the first round of test flights scheduled for late 2026, liquid hydrogen in the tanks would be directly combusted in a modified turbofan engine from CFM International, a joint venture between GE and Safran.

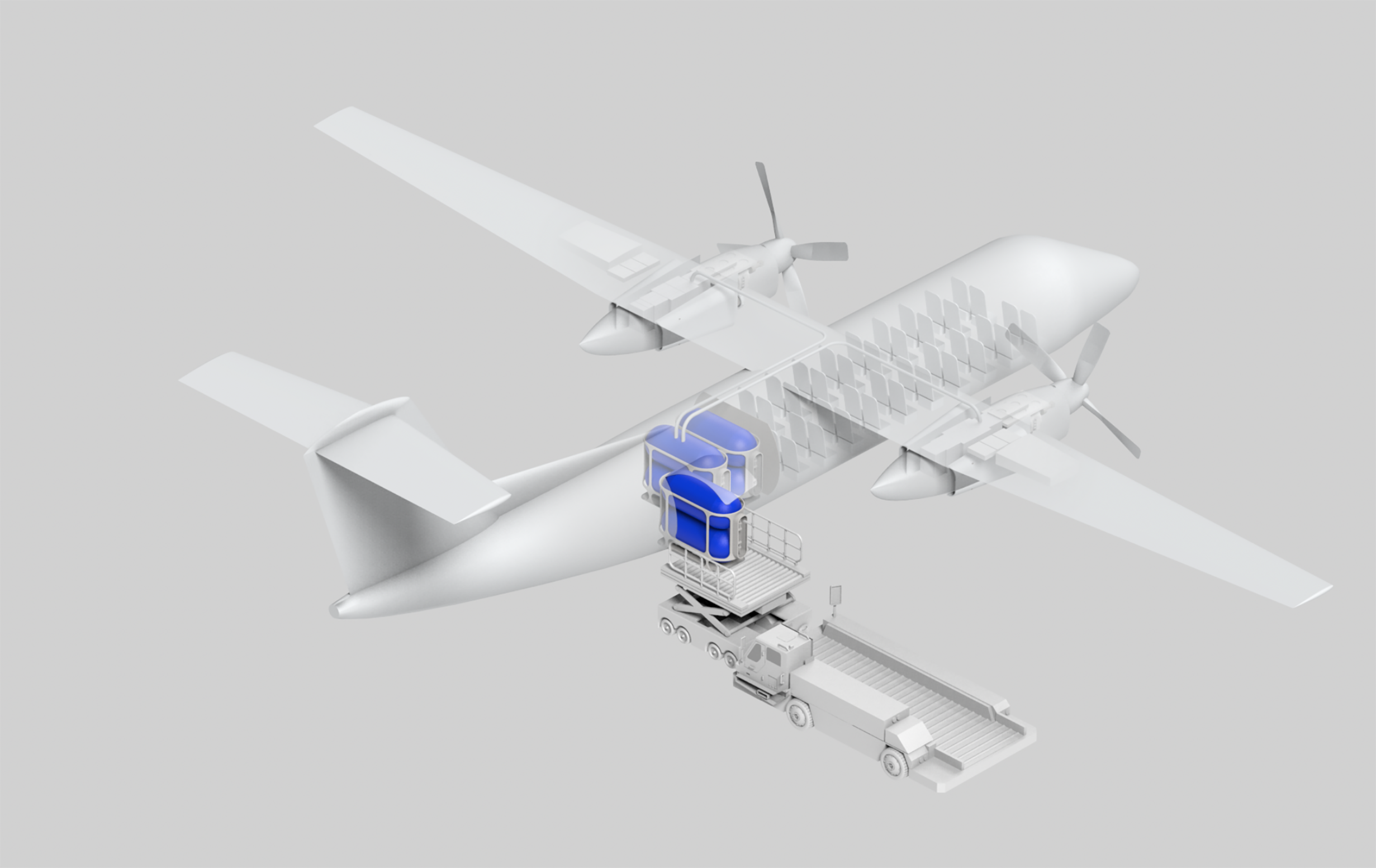

Similarly, California startup Universal Hydrogen plans to use aluminum to construct the liquid hydrogen tanks that would be part of the company’s first product: retrofit kits for converting today’s turboprop regional planes to hybrid-electric ones. The company wants to begin selling the kits — consisting of the fuel tanks, electric motors from magniX of Washington and fuel cells from Plug Power in New York — to regional airlines in 2025.

“We don’t really need to go to composite tanks to solve the regional aircraft — the problem that we’re trying to address now,” says Mark Cousin, chief technology officer at Universal Hydrogen.

That doesn’t mean that the company is ditching composite materials completely, however. Universal Hydrogen is also constructing composite tanks for gaseous hydrogen. Because it does not need to be kept at cryogenic temperatures, the fuel is easier to store and transport in that form. The gaseous tanks could also power collections of fuel cells or electric motors for regional aircraft conducting shorter-range flights. These high-pressure vessels would consist of inner and outer layers made from carbon fiber, either wound or braided around a plastic or metallic liner, according to Cousin.

Ultimately, the decision of whether to choose metals or composites will come down to a variety of factors, Johnson the NASA engineer told me by email. Some companies may consider the composite tank technology not mature enough and therefore risky for near-term applications, or that one material works better than the other for a particular aircraft market.

Companies will ask themselves these questions and more as they refine their tank designs, he said. That’s “part of the technology development cycle.”

For Universal Hydrogen, the reason is quite simple: metallic tanks are well-understood. “With a metallic-type design, we’re really not inventing anything new,” Cousin says. “We don’t have any particular problems with the materials for a metallic cryogenic tank.”

New airframes for new tanks

Regardless of what they are made of, there is at least one thing that the various hydrogen tanks will have in common: their shapes.

“It’s better to have something which is cylindrical or spherical and not having something which is square or flat” like the fuel tanks in today’s airliners, says Airbus’ Andriamisaina. And this isn’t just true for hydrogen; manufacturers favor cylindrical tanks for storing many kinds of gas because the shape evenly distributes pressure across the tank, improving storage efficiency.

This new shape requires a departure from the centurylong method of placing fuel tanks in the wings of regional jets and, in the case of passenger airliners, also in the center section. Instead, hydrogen tanks would need to be placed in the fuselage. Airbus’ current plan places the tanks in the rear part of the fuselage, Andriamisaina says, though he adds that the design has not been finalized. For regional jets, Universal Hydrogen is also planning to do the same by removing a few seats from the back of the aircraft.

“So we’re reducing a 70-passenger airplane to a 55-passenger airplane, for example,” Cousin says.

Storing hydrogen tanks in an aircraft’s fuselage could sound scary to passengers as hydrogen, like other fuels, is highly flammable and could easily be ignited. Something unique is the extremely small size of the hydrogen molecules. This means some could escape the container, even slipping through the densest potential tank material of all, a layer of steel. But Johnson and the other experts say there aren’t undue safety concerns for hydrogen, especially since other industries have been using hydrogen safely for decades.

“We believe that hydrogen is as safe as kerosene,” Andriamisaina says.

He adds: “We will never make any compromise on the safety. I can tell you, when I make my project objective, safety is the objective No. 0” — the absolute top of the list.

To ensure safety, Airbus plans to place active detection sensors for hydrogen and oxygen in the ZEROe demonstrator that would be capable of detecting any leaks in milliseconds. Additionally, the hydrogen valves will be insulated to prevent leakage, and there will be active and passive hydrogen ventilation systems to avoid hydrogen from concentrating in any part of the aircraft.

“Safe hydrogen is just a matter of taking the right precautions and using the state-of-the-art technologies,” he says.

NASA’s Johnson says history has unfairly tainted the American public’s view of hydrogen. Even though there have been successful hydrogen-powered flights in the past — most notably the Soviet Union’s Tu-155 airliner that first flew on hydrogen in 1988 — the phrase “hydrogen aviation” conjures up images of the 1937 Hindenburg airship disaster that killed 36 people.

Despite the obstacles, Cousin makes a bold prediction.

“I think by the end of this decade, [hydrogen] will be a major player in the regional aircraft business,” he says.

And once that happens, public pressure will grow for Airbus and Boeing to craft new hydrogen-powered designs for the single-aisle market.

“If companies expect to be able to launch an airplane in 2035 that still burns dinosaur juice, I think they’re going to find that that’s difficult to do,” he says.

“Safe hydrogen is just a matter of taking the right precautions and using the state-of-the-art technologies.”

Mathias Andriamisaina, Airbus