Symbiosis: Why CFD and wind tunnels need each other

By Joe Stumpe|June 2018

As powerful as computational fluid dynamics and supercomputing are, they have not come close to relegating wind tunnels to history. In fact, in the U.S., a new tunnel is going up at MIT, and NASA is deliberating whether it should close a historic tunnel at NASA’s Langley Research Center in Virginia four years from now as planned.

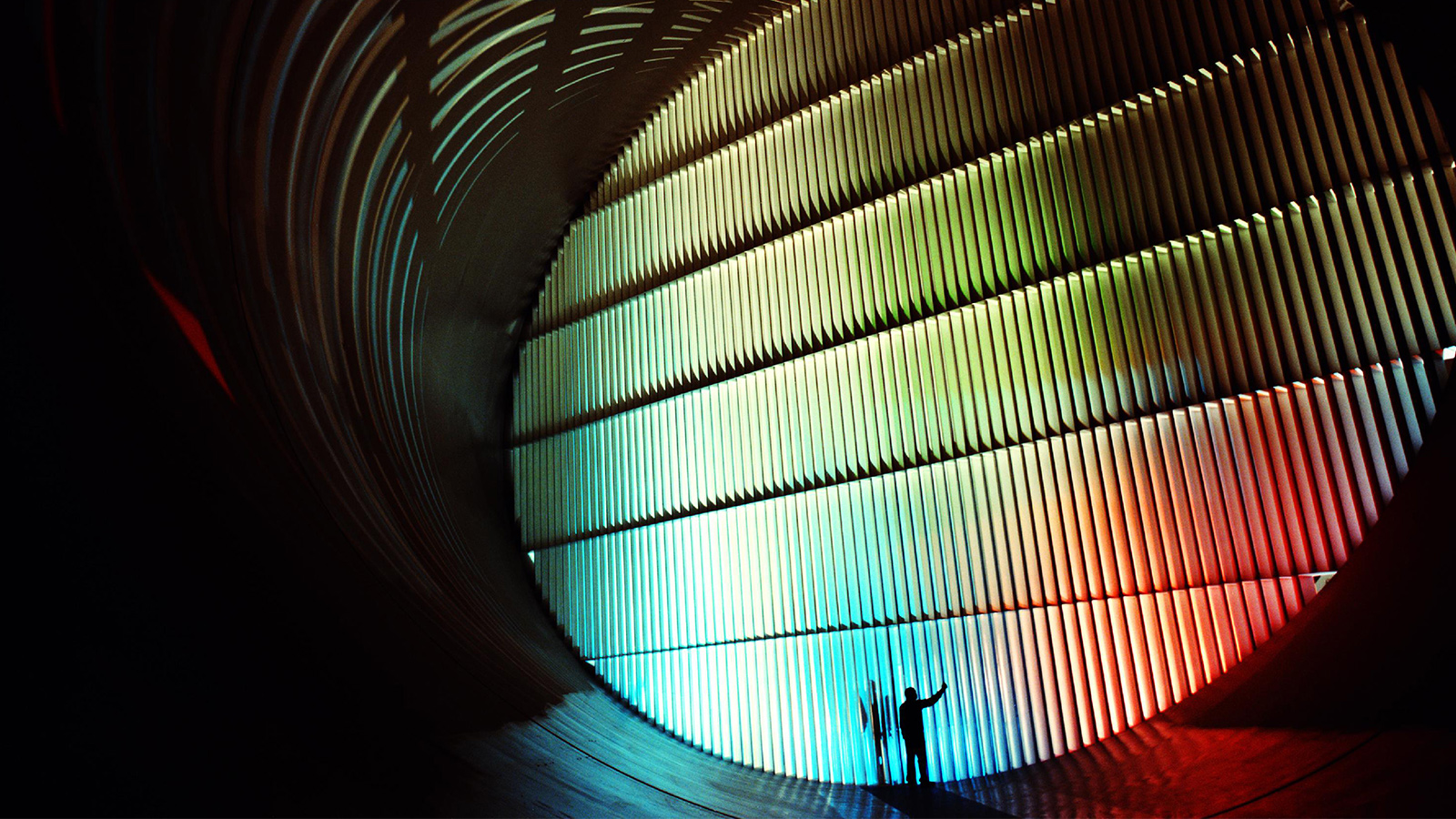

As an engineer doing research under contract for NASA in the 1980s, Scott Imlay remembers what it took to fire up the agency’s 16-foot Transonic Tunnel in Virginia, whose massive fans were driven by a 60,000-horsepower motor.

“At that time, you could only run it at night, it pulled so much power off the grid,” he tells me from his office at Tecplot, an aerospace engineering software company in Washington state where he is chief technical officer.

To gather data, engineers at this and other wind tunnels learned to introduce streams of dye or smoke into the airflow or to attach strings to the airframe or airfoil so they could see air flowing across it.

To Imlay and others, the advent of computational fluid dynamics seemed to promise a more efficient way of determining airflow. For instance, it takes time to repeatedly attach string or set up a smoke wand in a wind tunnel, while a CFD can run certain visualizations in a minute or two — at any time. CFD can also predict performance under extreme velocity, pressure and other conditions that wind tunnels cannot reproduce.

Nearly four decades later, wind tunnels retain a key role in aerospace engineering and probably will for some time. Engineers don’t generally take a one-or-the-other view of CFD compared to wind tunnels. CFD reduces the scope of expensive wind tunnel testing, but time in tunnels is still required to validate far-reaching designs or even aspects of conventional designs that CFD software cannot yet model well enough. Researchers attach sensors to models in wind tunnels to measure the pressure exerted on their surfaces. Equations scale up the data to help designers measure how the aircraft would perform if it were actually flying.

“I don’t really ever see wind tunnels going away, personally,” says Carolyn Woeber of Pointwise in Fort Worth, Texas, which like Tecplot designs software for CFD. “There are still so many unsolved problems when it comes to fluid dynamics.”

The most recent count of wind tunnels in operation in the United States that I could find came in a 2010 report by Lockheed Martin researchers. It showed the number falling from 120 in 1985 to 61 in 2009 as CFD became more common.

NASA is a major operator of tunnels, but not the only one. The agency operates 14 “critical” wind tunnels at centers in California, Ohio and Virginia at a cost of about $100 million a year, plus 20 smaller tunnels. These tunnels are not just for NASA researchers. Private industry and other government agencies conduct experiments in them. NASA has mothballed about 60 tunnels over the past several decades.

As one indication of CFD’s progress, NASA is evaluating whether to stick with a plan to close a historic supersonic wind tunnel at its Langley Research Center in Virginia in 2022. Everything from Mercury spacecraft in the 1950s to commercial space vehicles from Boeing and SpaceX have been tested there.

But wind tunnels are hardly headed for extinction anytime soon. MIT announced in November that it will replace its 79-year-old subsonic Wright Brothers Wind Tunnel with an $18 million version it describes as “the largest and most advanced academic wind tunnel in the United States.”

For wind tunnels to become a thing of the past decades from now, CFD would first have to be brought to the point where it can supply some of the most complex and critical data needed in aerospace design — data that engineers now rely on wind tunnels to provide. One area where the physics of CFD still falls short is in predicting turbulent flows, which are irregular, drag-inducing patterns of airflow created off an airfoil by a high angle of attack and other conditions.

CFD models “work really well for problems that are ‘nice,’ in quotes,” Imlay tells me by phone. “If you’re flying in cruise conditions they work really well. If you get out of nice regions, they don’t work so well.” Engineers can’t mimic that turbulence “on computers we have or will have in 20 years.”

CFD is also inadequate for modeling conditions at a high angle of attack, such as when the wings are pitched up so high relative to the airflow that the plane is close to stalling. “That’s a big concern to airplane companies,” Imlay says. “You’re close to that region every time you land an airplane.”

Aeroacoustics — the sound generated by aircraft — and vortices created at the tip of rotor blades are two more areas where the current batch of CFD codes “don’t do so well,” Imlay says.

David Schuster, a NASA technical fellow at Langley, says CFD “might have advanced further than we anticipated, but it’s still not in any position to do a full flight analysis of aircraft and spacecraft.” As an example, he says CFD modeling has not proved as helpful as hoped in calculating re-entry conditions for the Orion crew capsule that Lockheed Martin is building to carry astronauts to the moon and Mars.

“We had envisioned that since it was so much like Apollo we would be able to do virtually all of our aerodynamic analysis using CFD,” he says. However, Orion’s size, construction materials and other features led the agency to rely on wind tunnel testing “as much as with the original Apollo in the 1960s.” Schuster adds, though, that the use of CFD in conjunction with wind tunnel testing on the Orion means the agency’s analysis is “much more refined” than it would be otherwise.

Schuster predicts that wind tunnels will be used at their current rate for the next 10 years or so.

NASA, in a 2014 report titled “CFD Vision 2030 Study,” said improvements in CFD would happen only by improving the algorithms, software and hardware, requiring significant infusions of government and private funding.

CFD, as the report noted, has already dramatically altered the aerospace design process. A detailed physical model of an aircraft to be tested in a wind tunnel, made of metal with moving parts, might cost $1 million to produce — not to mention the costs of running a tunnel, which can be $20,000 per hour. By first testing simulated models through CFD, Woeber says, “Maybe instead of making 20 or 30 different models for a wind tunnel, they can narrow it down to the two or three that have the most promise.”

As Woeber notes, “Initially when CFD came out, most experimentalists were quite suspicious of it. I think with good cause. We didn’t know if we could trust the data.”

However, with every successful validation, confidence in CFD increases.

Still, with CFD’s limitations, it’s more efficient to test certain scenarios in a wind tunnel — for instance, a plane in landing configuration, with its wheels down and flaps out.

“That’s a case where I think most [aerospace] companies do it in a wind tunnel,” Imlay says.

Wind tunnels have their own limitations, Imlay notes, such as being unable to simulate the Mach 24 or Mach 26 speeds of a vehicle entering the atmosphere from space. He estimates that the ratio of wind tunnel-to-CFD use in aerospace design is “about 50-50.”

“If it’s a change to a design, like adding something, it’s probably going to be done with CFD. If it’s a brand-new airplane, they may do some wind tunnel” tests.

The Wright Brothers Wind Tunnel (named for the aviation pioneers but never used by them) opened at MIT in 1938. The school hopes to break ground on its upgrade in the coming months. Mark Drela, director of the tunnel, says wind tunnels are necessary because “there are a lot of things you can’t compute with sufficient confidence. It’s that simple. The geometry or physics may be too complicated.”

NASA is studying whether it needs the Unitary Plan Wind Tunnel at NASA’s Langley Research Center in Virginia. In use since the 1950s, it’s scheduled to be dismantled in 2022. However, it could have its lifespan extended if the agency were to decide it’s still needed.

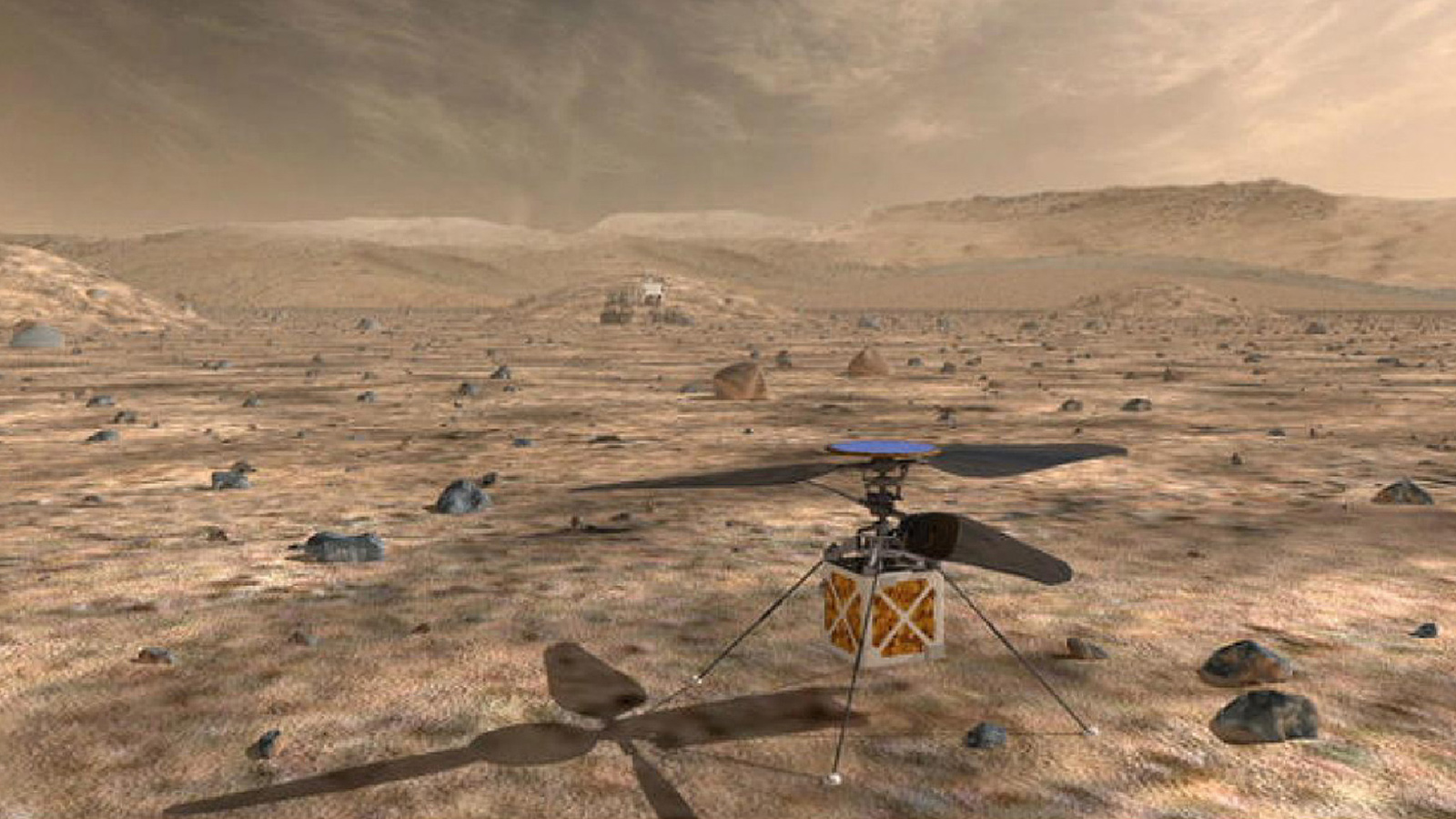

The agency plans to compare data from the tunnel with CFD simulations for four vehicles that would fly between Mach 2.6 and Mach 6 speed: an entry capsule, launch vehicle, hypersonic aircraft and capsule that would be subjected to supersonic retro propulsion, as if it were landing on Mars. “Somebody brought up the thought that if there was any speed regime that CFD was ready to take over the wind tunnel in, it was this supersonic regime,” Schuster says. “The whole purpose [of the study] is to understand just how true that statement is — if we were to close the tunnel down and rely on CFD, how much more risk would we be taking as an agency in going down that analysis path?”

In addition to accuracy, the agency will consider efficiency. Echoing Imlay’s comments, Schuster says there is certain data that a wind tunnel test can generate “in literally 30 seconds,” while calculating it using CFD would take weeks. Schuster says the study, in which researchers at all three of NASA’s main wind tunnel sites are participating, is expected to take about five years and will be presented to “management at headquarters level.” The concern of engineers, Schuster says, “is that a problem we don’t envision today will crop up in the future when we don’t have the [wind tunnel] test capability and we aren’t confident in the CFD for the specific problem under consideration.”

Whatever the fate of that wind tunnel, some engineers believe the devices that helped usher in manned flight will never completely disappear.

“We will always need to go into wind tunnels,” says Bob Stuever, a safety and certification engineer at Textron Aviation who is part of the team designing the Cessna SkyCourier. Planes “are just too complex. There are things you can’t model.”

The NASA photo at the top of this story shows the 16-foot Transonic Tunnel at NASA Langley Research Center in Virginia.

“There are a lot of things you can’t compute with sufficient confidence [with CFD]. It’s that simple.”

Mark Drela, director of MIT’s Wright Brothers Wind Tunnel